Multi-air-channel stopper rod

A multi-air channel and stopper technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of single argon blowing function and affect the quality of billet, and achieve a balanced and stable flow field of molten steel, ensuring Quality, the effect of preventing slag entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

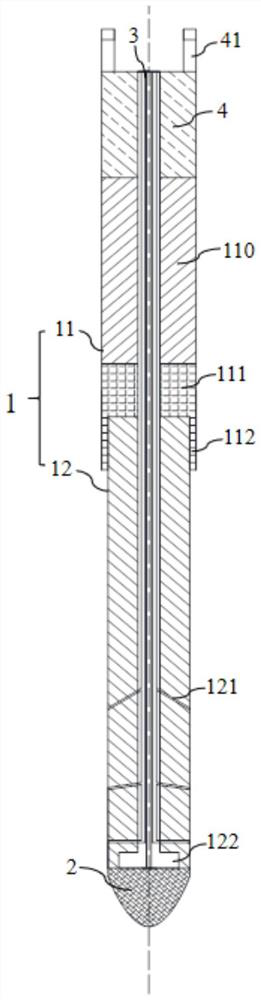

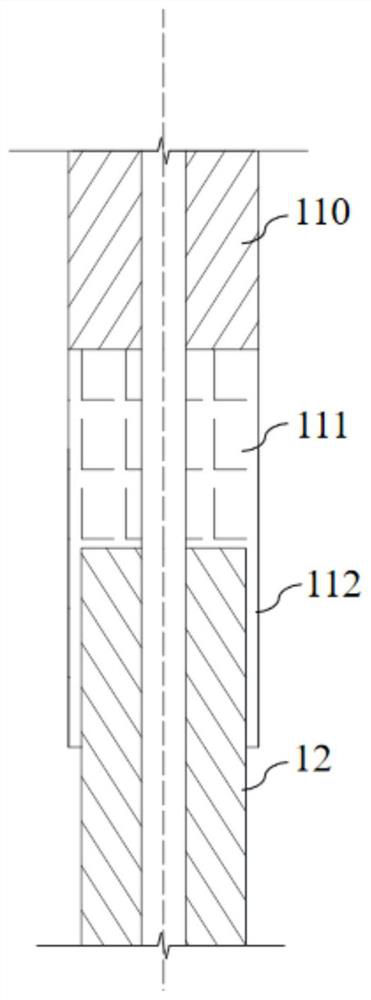

[0038] like figure 1As shown, a multi-airway stopper rod of this embodiment includes a stopper rod body and a stopper rod head 2, the bottom of the stopper rod body is connected to the stopper rod head 2, the stopper rod body includes a stopper rod shell 1 and a rod core 3, and the stopper rod body The rod core 3 is nested in the inner layer of the rod shell 1 . Wherein, the rod core 3 is prepared separately from the stopper shell 1, and the main material of the rod core 3 is high temperature resistant metal. The stopper shell 1 has a plurality of sets of side channels 121 communicating inside and outside, and the core 3 contains an argon gas channel, an important part of the stopper rod. The inner side channel 121 and the bottom argon channel are connected, and each argon channel is made of refractory material, and the argon flow can be controlled in groups from the outside. By setting multiple sets of side channels 121 in the stopper shell 1, the argon flow can be blown ou...

Embodiment 2

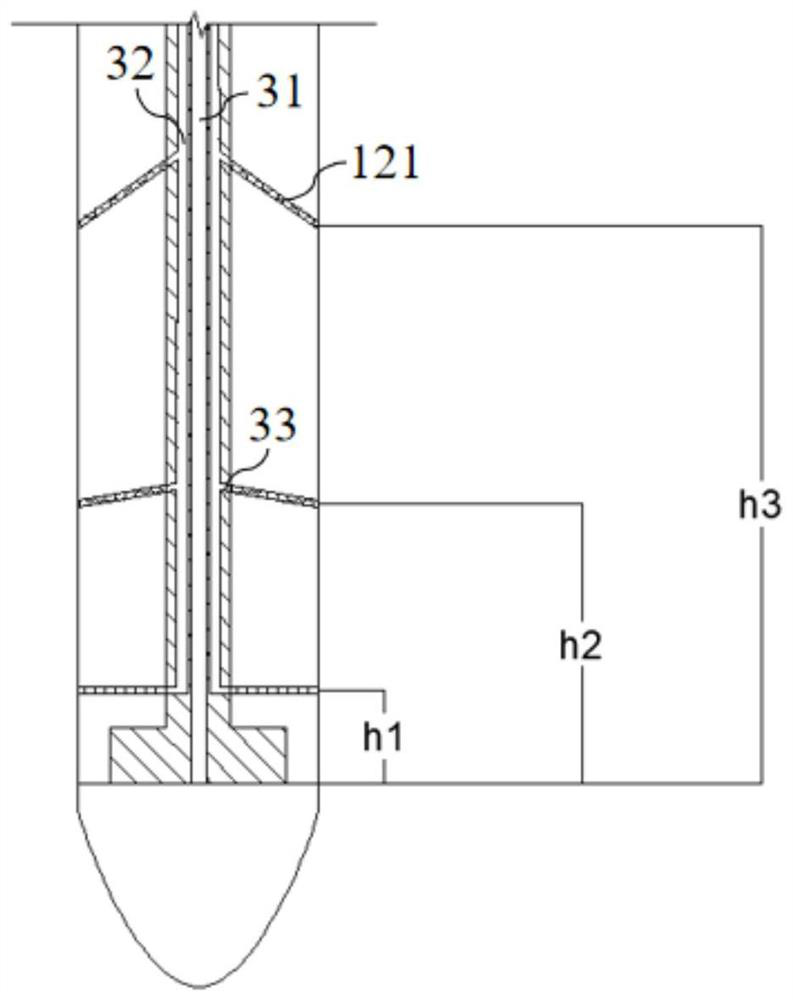

[0047] A kind of multi-airway stopper rod in this embodiment, its structure is basically the same as embodiment 1, and its main difference is: the specific structure of described rod core 3 is different, as Figure 5 As shown, the rod core 3 is designed with a special argon gas channel, which has an axial through pipe as the main channel 31, the upper part is the entrance, and the lower part is connected to the lower rod head. The rod core 3 is provided with six branch channels 32, Each branch channel 32 is provided with a plurality of air guide holes 33 along its axial direction, and an annular transition channel 5 is arranged between the two branch channels 32 distributed symmetrically with the main channel 31, and the branch channels 32 are located at the same height. The air guide holes 33 are connected through the transition channel 5, and the transition channel 5 communicates with the side channel 121, and the connection between the side channel 121 and the transition cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com