Submersed nozzle with trumpet-shaped outlet and using method thereof

A trumpet-shaped, immersed technology, applied in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems affecting the quality of continuous casting billets, secondary oxidation of molten steel, and the impact of continuous casting production, and reduce leakage. Effects of steel risk, extended service life, improved erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

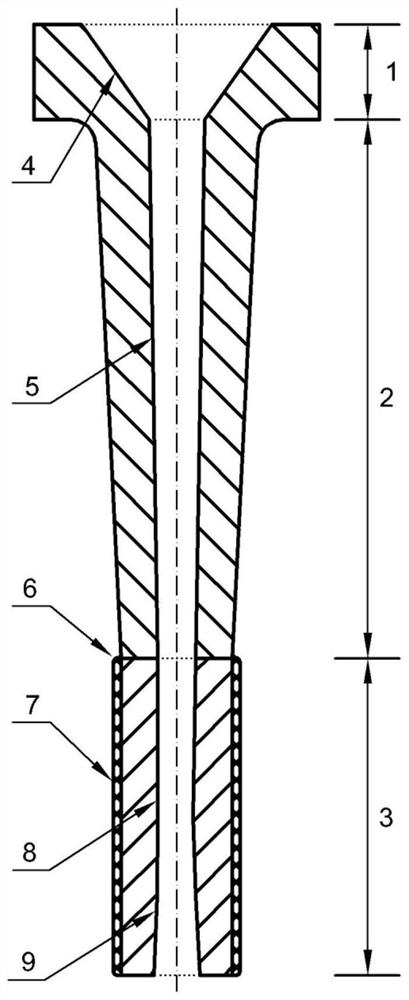

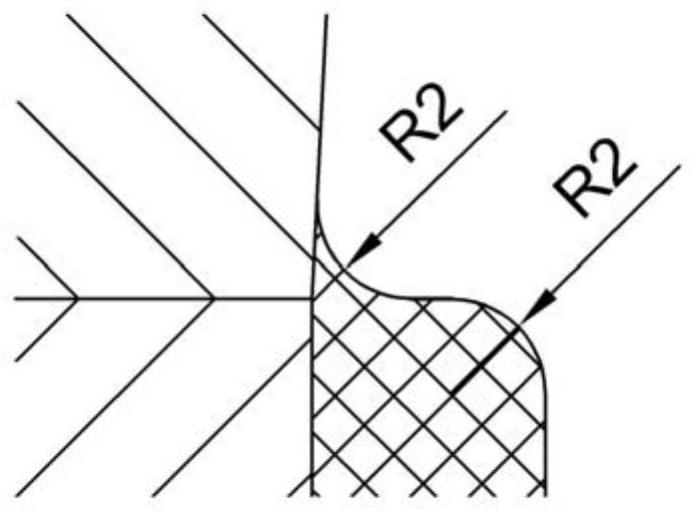

[0026] combine Figure 1-2 As shown, the present application provides a submerged nozzle with a trumpet-shaped outlet and its use method. A trumpet-shaped outlet 9 is provided in the inner cavity at the lower end of the submerged nozzle, with a radius of curvature of 1000 mm and a length of 100 mm.

[0027] The length of the main body of the nozzle is 700mm, the upper inner diameter of the inner cavity 4 of the nozzle chuck 1 is 110mm, the lower inner diameter is 35mm, and the length is 70mm.

[0028] The length of the conical section 2 of the nozzle is 430 mm, the inner diameter of the inner cavity 5 of the conical section of the nozzle is 25 mm, and the upper inner diameter thereof is equal to the lower inner diameter of the inner cavity 4 of the nozzle chuck.

[0029] The length of the nozzle vertical section 3 is 200mm, and the outer diameter is 70mm, and its upper inner diameter is equal to the lower inner diameter of the inner cavity 5 of the nozzle tapered section. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com