Constructional column for low multi-layer building and construction method thereof

A construction method and a technology for constructing columns, which are applied in the direction of building structures, buildings, columns, etc., can solve the problems of slag dropping at pre-buried places and easy falling off of prefabricated bolts, and achieve the effect of avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

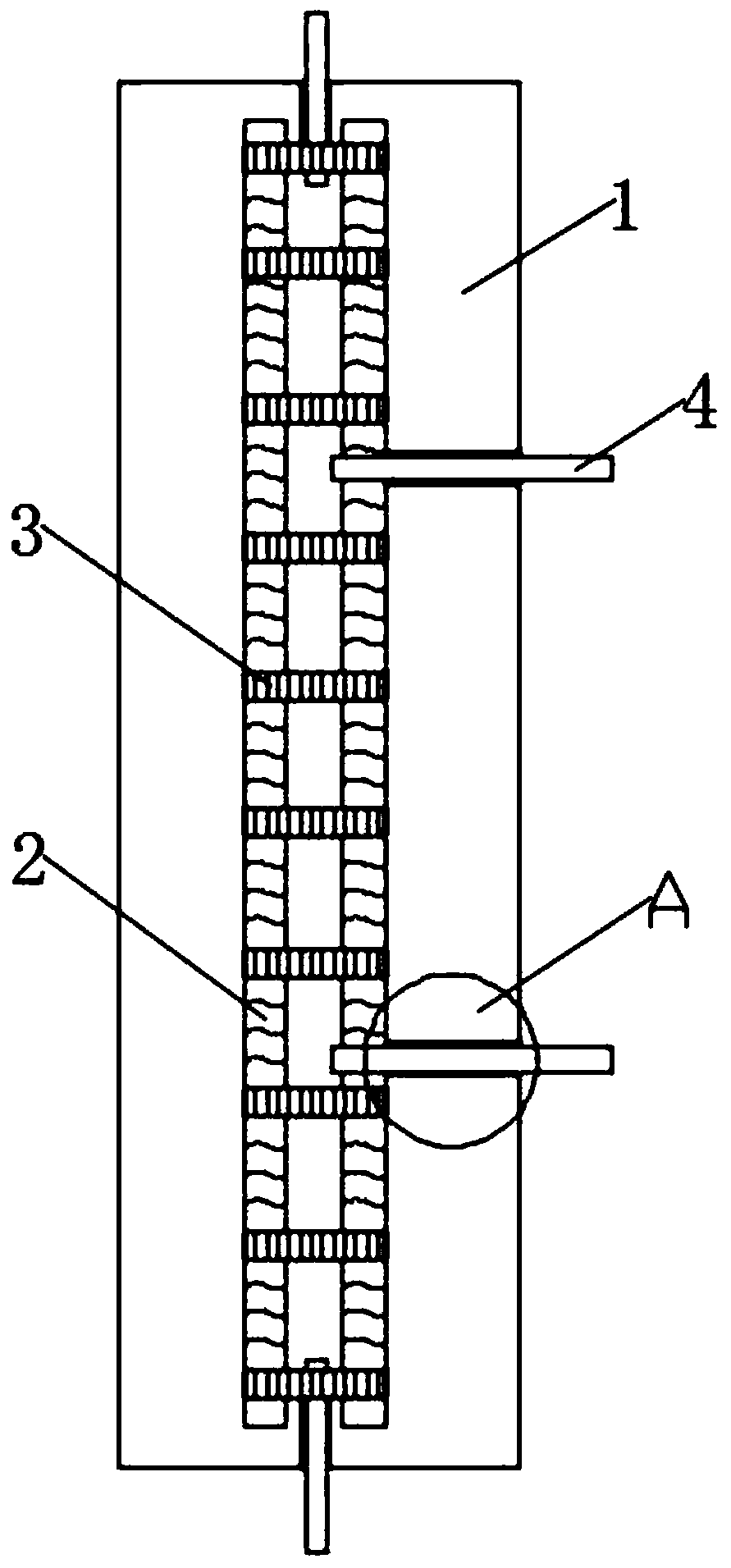

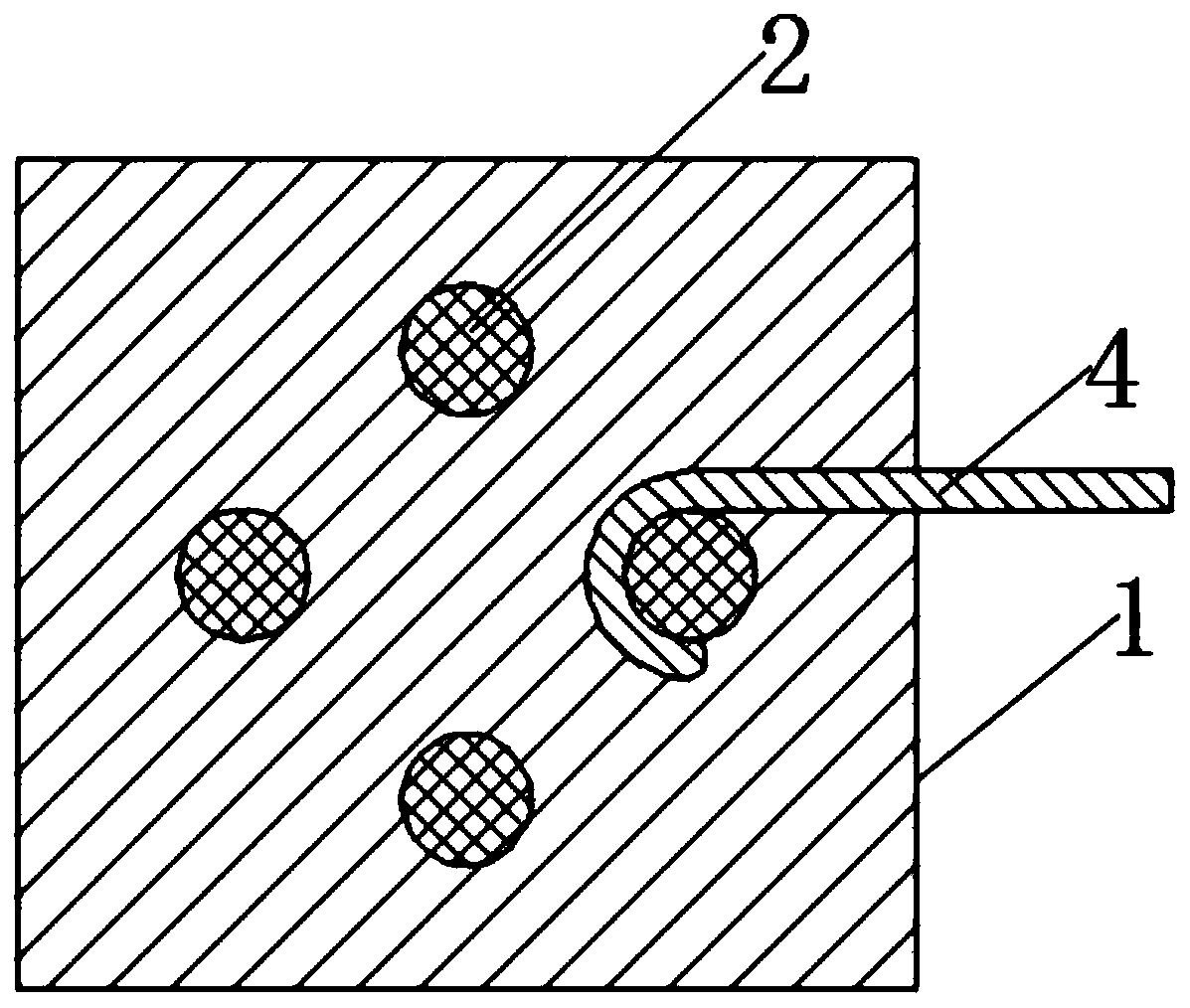

[0034] like Figure 1-Figure 3 As shown, a structural column for low-rise buildings includes a structural column body 1, and four longitudinal ribs 2 parallel to each other and arranged in a rectangular array are arranged in the structural column body 1, and the longitudinal ribs 2 are made of rebar , the rebar steel has excellent bending resistance, and its surface is not easy to produce cracks. Using rebar as the longitudinal reinforcement 2 can strengthen the overall structural stability of the structural column. The longitudinal reinforcement 2 is arranged along the length direction of the structural column body 1, and the four longitudinal reinforcement 2 A number of binding bars 3 are nested along the length direction, and prefabricated bolts 4 are pre-embedded on the top, bottom and side surfaces of the structural column body 1, and the prefabricated bolts 4 pre-embedded on the side of the structural column body 1 are located at the top of the structural column body 1. ...

Embodiment 2

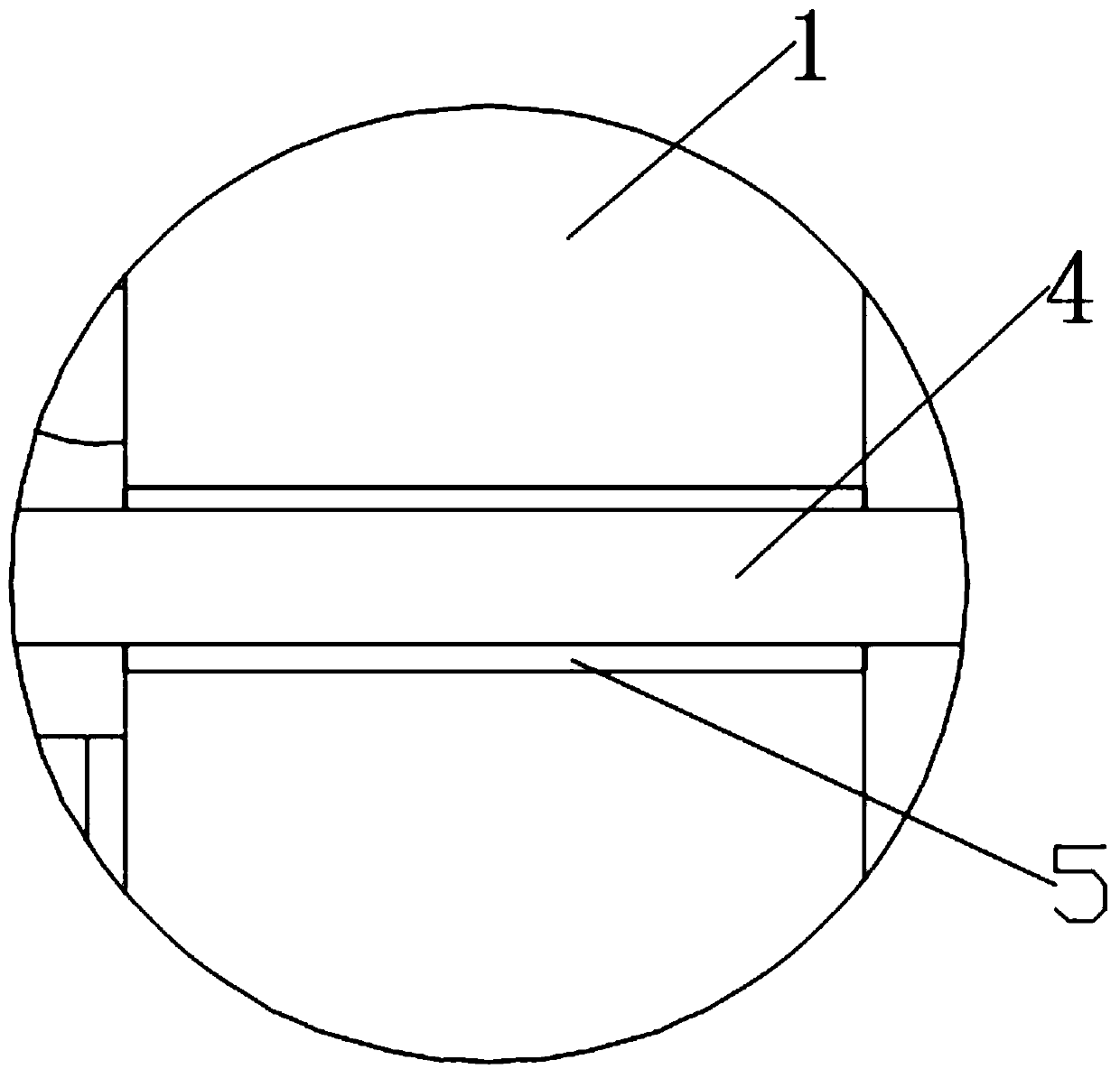

[0045] like figure 1 and image 3 As shown, in this embodiment, on the basis of Embodiment 1, the part of the prefabricated bolt 4 located in the construction column body 1 is tightly sleeved with a PVC pipe 5, and one end surface of the PVC pipe 5 is connected to the structure The surface of the column body 1 is even.

[0046] The PVC pipe 5 is fastened on the part where the prefabricated bolt 4 is located in the construction column body 1, and the outer end face of the PVC pipe 5 is flush with the surface of the construction column body 1, so that it can prevent that during the installation process, Due to the need to calibrate and adjust the position of the construction column, when the relative swing of the prefabricated bolt 4 relative to the construction column occurs, damage will be caused to the pre-embedded place of the prefabricated bolt 4 on the surface of the construction column, resulting in slag falling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com