Stepped tundish and casting control method thereof

A tundish and step-type technology, applied in the field of iron and steel metallurgy, can solve the problems of high requirements, difficult casting control in the process of stopping pouring, large amount of residual steel, etc., and achieve the effect of preventing slag entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

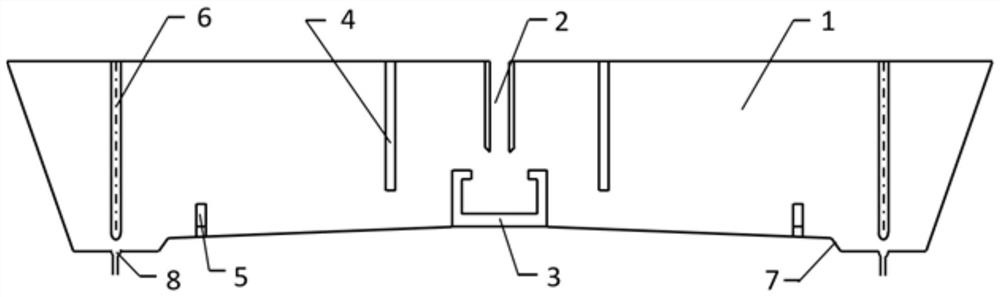

[0030] Combine figure 1 As shown, a dual flow step-in-band, including: Body 1, long water port 2, suppressor 3, upper retaining wall 4, damper 5, plunger 6 and upper water mouth bowl 8, long water port 2 and plug The rod 6 is fixed to the encapsulation body 1, and the suppressor 3 is mounted below the long water port 2, and the upper retaining wall 4 and the damper are located between the plug rod 6 and the long water port 2, and the upper retaining wall is located near the long water port 2 side, The bottom portion is located between the plug rod 6 and the baffle 5, and the body 1 is inclined toward the step portion 7 side to the step portion 7 side, and the inclination angle is 2-3 °. The upper retaining wall 4 includes two upper retaining walls mounted on both sides of the long water port 2; the damper 5 includes two dams disposed between the upper retaining wall 4 and the plunger 6 side sides of the long water port. 5; the damper 5 and the horizontal plane are vertically mount...

Embodiment 2

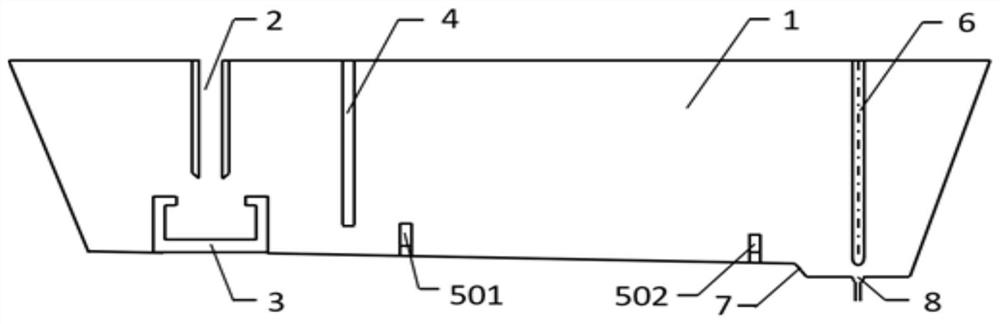

[0040] Combine figure 2 As shown, a single-flow step-in-one intermediate package, including: Body 1, long water port 2, suppressor 3, upper retaining wall 4, dam, plunger 6 and upper water mouth bowl 8, long water port 2 and plug The rod 6 is fixed to the encapsulation body 1, and the suppressor 3 is mounted below the long water port 2, and the upper retaining wall 4 and the first damper 501, the second damper 502 is located between the plug rod 6 and the long water port 2, and the upper retaining wall 4 is located adjacent to the long water port 2 side, and the cover body 1 is located between the plug rod 6 and the second bars 502, and the body 1 is in the bottom side of the inhibitor 3 to the step portion 7 side The lower inclinement is 2-3 °. The distance from the lower end distance of the upper retaining wall 4 is 150-300 mm. The preferred distance from the lower end distance of the upper retaining wall 4 is 200-250 mm. The upper retaining wall 4 and the plug rod 6 are provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com