System and method for improving characteristics of coal as fired of slag tapping furnace by utilizing fly ash circulation

A technology of liquid slag discharge and coal characteristics, applied in the field of coal chemical industry, can solve the problems of safe and stable production test, high cost, high production and operation pressure of enterprises, achieve long-term operation, prevent gasifier slag collapse or slag blocking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

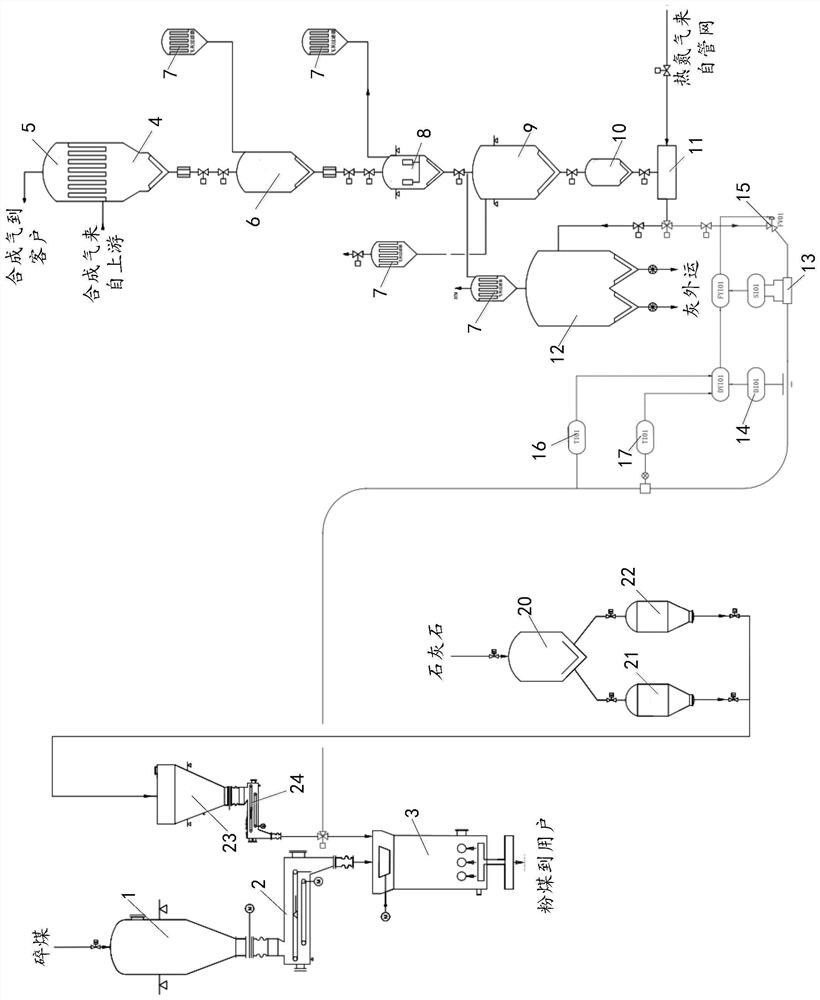

[0054] In this embodiment, the system for improving the coal characteristics of the liquid slagging furnace by using fly ash circulation includes a fly ash return device, a quantitative addition device and a fly ash collection device. The fly ash return device is connected to the fly ash collection device. The ash conveying device presses the fly ash from the fly ash collection device to the coal grinding system through pneumatic conveying, and the quantitative addition device controls the amount of fly ash added synchronously through the feeding chain of fly ash and raw coal. The gasifier is connected to the air inlet of the fly ash collection device through a pipeline through a fly ash return device, and the fly ash outlet of the fly ash collection device is connected to the coal grinding system through a fly ash circulation pipeline.

[0055] Such as figure 1 and figure 2 As shown, the coal grinding system includes a crushed coal bunker 1 and a pulverizer 3, the crushed c...

Embodiment 2

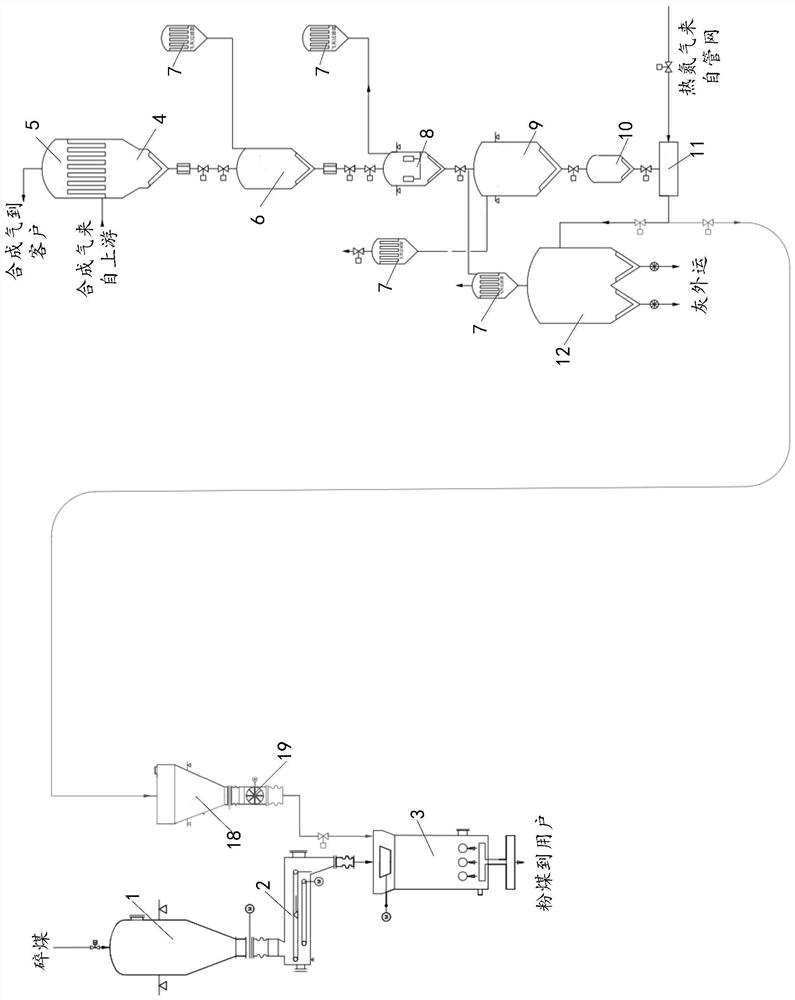

[0059] In this embodiment, the system for improving the coal characteristics of the liquid slagging furnace by using fly ash circulation includes a fly ash return device, a quantitative addition device and a fly ash collection device. The fly ash return device is connected to the fly ash collection device. The ash conveying device presses the fly ash from the fly ash collection device to the coal grinding system through pneumatic conveying, and the quantitative addition device controls the amount of fly ash added synchronously through the feeding chain of fly ash and raw coal. The gasifier is connected to the air inlet of the fly ash collection device through a pipeline through a fly ash return device, and the fly ash outlet of the fly ash collection device is connected to the coal grinding system through a fly ash circulation pipeline.

[0060] Such as figure 2 As shown, the system of this embodiment also includes a fly ash buffer bin 18, the quantitative addition device inc...

Embodiment 3

[0071] In this embodiment, the system for improving the coal characteristics of the liquid slagging furnace by using fly ash circulation includes a fly ash return device, a quantitative addition device and a fly ash collection device. The fly ash return device is connected to the fly ash collection device. The ash conveying device presses the fly ash from the fly ash collection device to the coal grinding system through pneumatic conveying, and the quantitative addition device controls the amount of fly ash added synchronously through the feeding chain of fly ash and raw coal. The gasifier is connected to the air inlet of the fly ash collection device through a pipeline through a fly ash return device, and the fly ash outlet of the fly ash collection device is connected to the coal grinding system through a fly ash circulation pipeline.

[0072] Such as figure 1 As shown, the quantitative addition device in this embodiment includes a speedometer, a flow regulating valve and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com