RH method vacuum tank with lifting gas pipeline and arrangement method of lifting gas pipeline thereof

A gas pipeline and arrangement method technology, applied in the field of RH method refining equipment, can solve the problems affecting the life of the lower groove of the vacuum tank, fast erosion rate, increase the cost of refractory materials, etc., to improve the life of refractory materials, reduce erosion erosion, reduce Effect of refractory cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

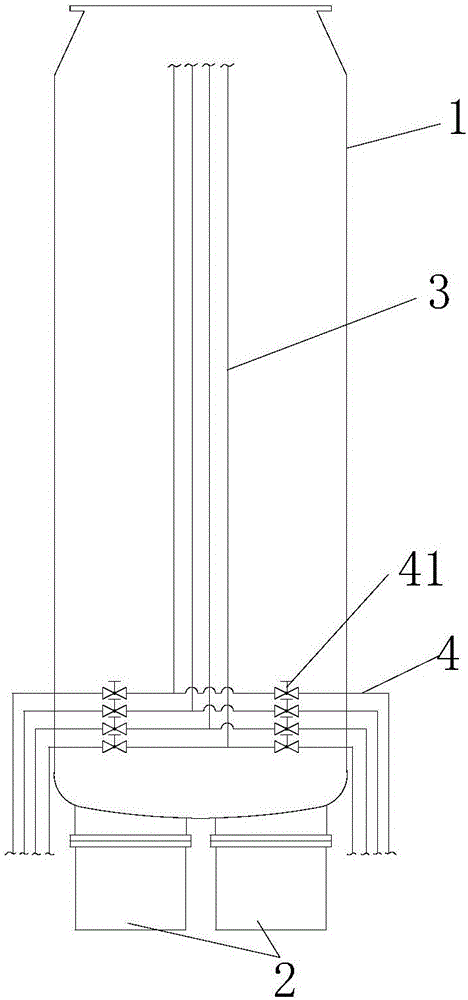

[0025] The present invention proposes a RH method vacuum tank with a lifting gas pipeline, comprising: a vacuum tank, the vacuum tank is vertically placed, and two dipping tubes are inserted at the bottom thereof, and the two dipping tubes are parallel to each other, and are respectively connected to The inner cavity of the vacuum tank is connected; at least one lifting pipeline is vertically arranged on the outside of the vacuum tank, and its lower end is connected with two branch pipelines, and a valve is respectively installed on the two branch pipelines. The free ends correspond to communicate with the two dipping pipes.

[0026] The present invention also proposes a method for arranging the lifting gas pipeline of the RH method vacuum tank, which includes the following steps: S1: Install two dipping tubes at the bottom of the vacuum tank placed vertically, and make the dipping tubes and the The inner cavity of the vacuum tank is connected; S2: At least one lifting pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com