A tundish composite flow control process and equipment for slab continuous casting machine

A technology of slab continuous casting machine and process equipment, which is applied in the field of steel plate casting, can solve the problems of difficulty in ensuring the stability of steel flow, rising of molten steel in the crystallizer, and affecting the life of the tundish, so as to reduce the erosion of stopper rods and reduce erosion Flushing, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

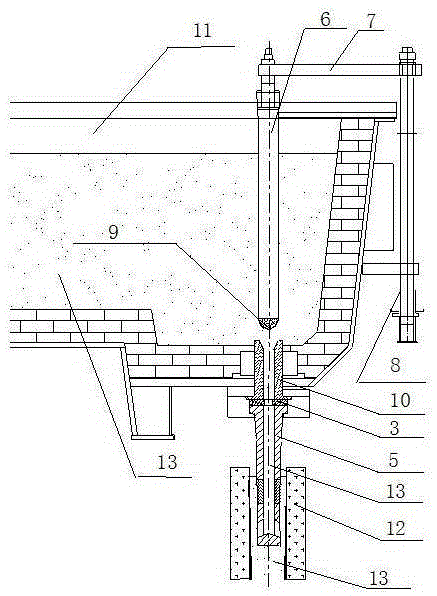

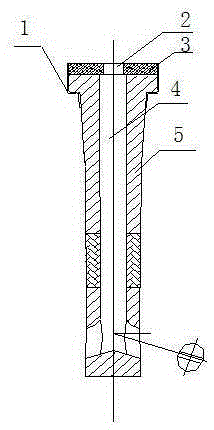

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings. The invention discloses a tundish composite flow control process for a slab continuous casting machine. The composite flow control process includes a stopper rod flow control operation stage and an immersed nozzle flow control stage, wherein the stopper rod flow control operation stage is applied in continuous casting In the low casting speed state of the machine, that is, the initial pouring of the tundish and the unsteady state of the continuous casting machine, the flow control stage of the submerged nozzle is applied in the normal casting speed state of the continuous casting machine. The stopper rod flow control operation stage refers to that the stopper rod head 9 is aligned with the upper nozzle 10, and the upper nozzle 10 is closed by the stopper rod 6 rising, lifting and lowering to complete the control of the size of the steel flow. The submerged nozzle flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com