A Method of Improving the Service Life of Converter Oxygen Lance

A converter oxygen lance and life-span technology, which is applied in the manufacture of converters, etc., can solve the problems of poor erosion resistance and failure to reach, achieve good slag removal, improve service life, and save processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]The treatment method to improve the life of the converter oxygen lance is divided into two parts: the treatment process of the bottom end surface of the oxygen lance nozzle and the treatment process of the side wall of the lance body.

[0042] Oxygen lance nozzle bottom surface treatment process:

[0043] 1) Use ultrasonic cleaning treatment on the bottom end surface of the oxygen lance nozzle to clean the residual dirt in the surface processing process;

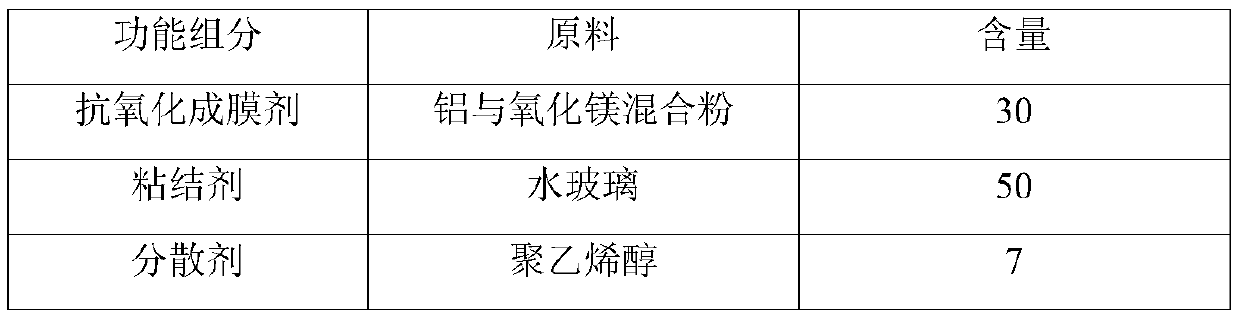

[0044] 2) Coating a layer of high-temperature-resistant anti-oxidation coating on the bottom end surface of the nozzle, the thickness of the coating layer is controlled at 0.2mm, and the composition of the coating is as shown in Table 1;

[0045] Table 1 coating composition and content (%)

[0046] functional components raw material content Antioxidant film former Aluminum and Magnesium Oxide Mixed Powder 35 binder water glass 45 Dispersant polyvinyl alcohol 8 D Titanium oxi...

Embodiment 2

[0055] The treatment method to improve the life of the converter oxygen lance is divided into two parts: the treatment process of the bottom end surface of the oxygen lance nozzle and the treatment process of the side wall of the lance body.

[0056] Oxygen lance nozzle bottom surface treatment process:

[0057] 1) Use ultrasonic cleaning treatment on the bottom end surface of the oxygen lance nozzle to clean the residual dirt in the surface processing process;

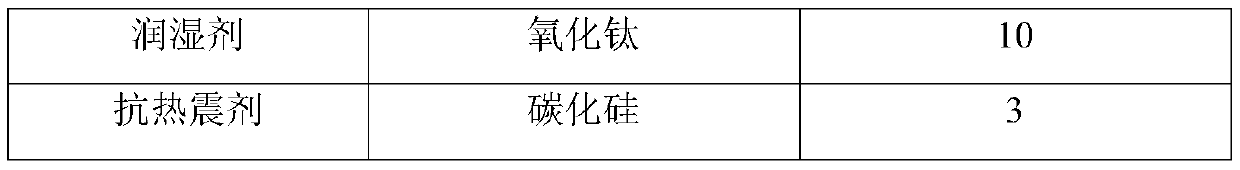

[0058] 2) Coating a layer of high-temperature-resistant anti-oxidation coating on the bottom end surface of the nozzle, the thickness of the coating layer is controlled at 0.3mm, and the composition of the coating is as shown in Table 2;

[0059] Table 2 coating composition and content (%)

[0060]

[0061]

[0062] 3) After the paint applied on the bottom end surface of the nozzle is solidified and dried, conduct induction heating or flame heating treatment on the end surface, and heat the surface to 800°C;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com