Shaping refractory material converter protection method for converter

A technology of refractory materials and converters, which is applied in the manufacture of converters, etc., can solve the problems of repairing materials blocking the bottom blowing capillary, affecting the ventilation effect, and existing safety hazards, so as to reduce the consumption of gunning materials, reduce production costs, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

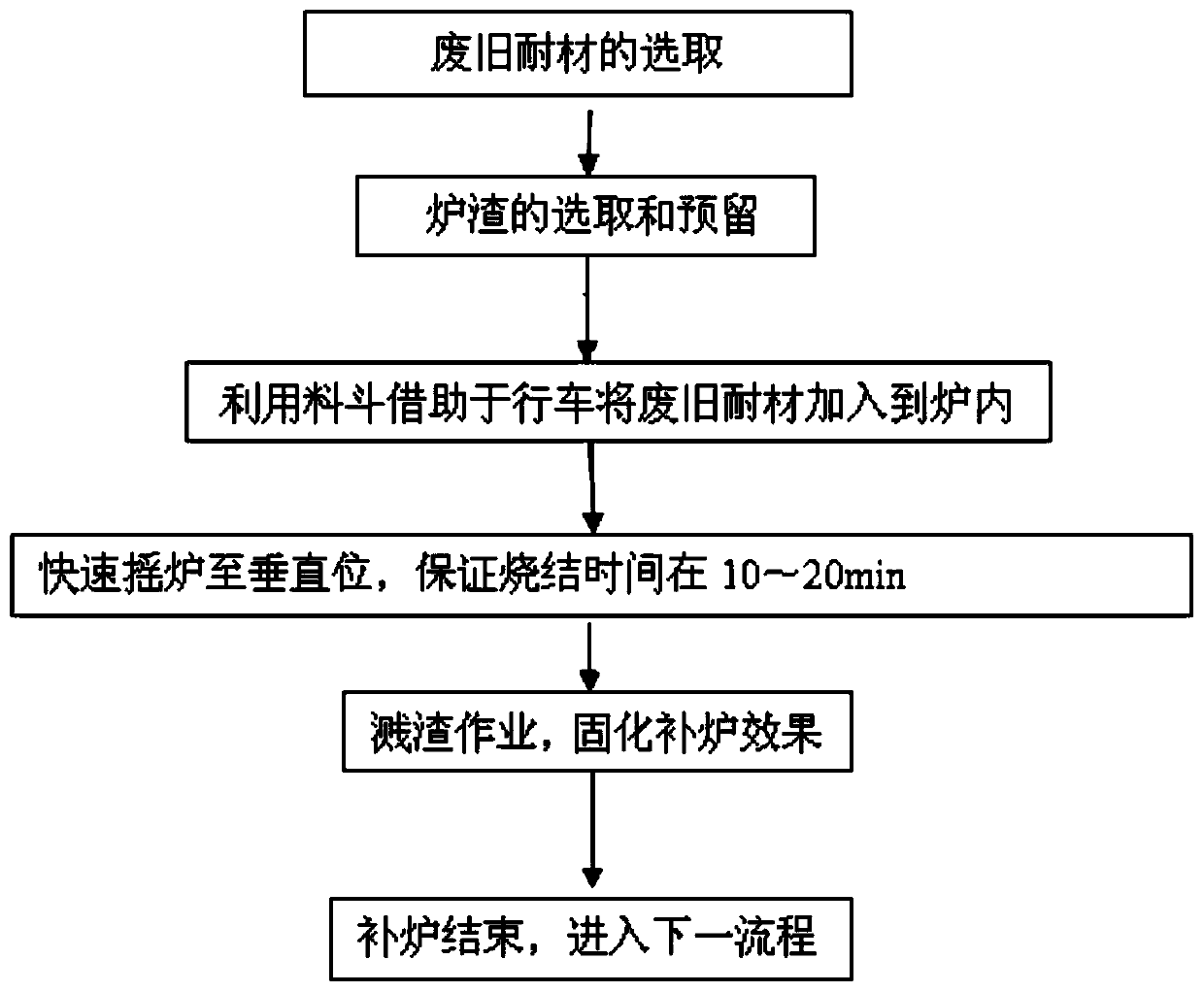

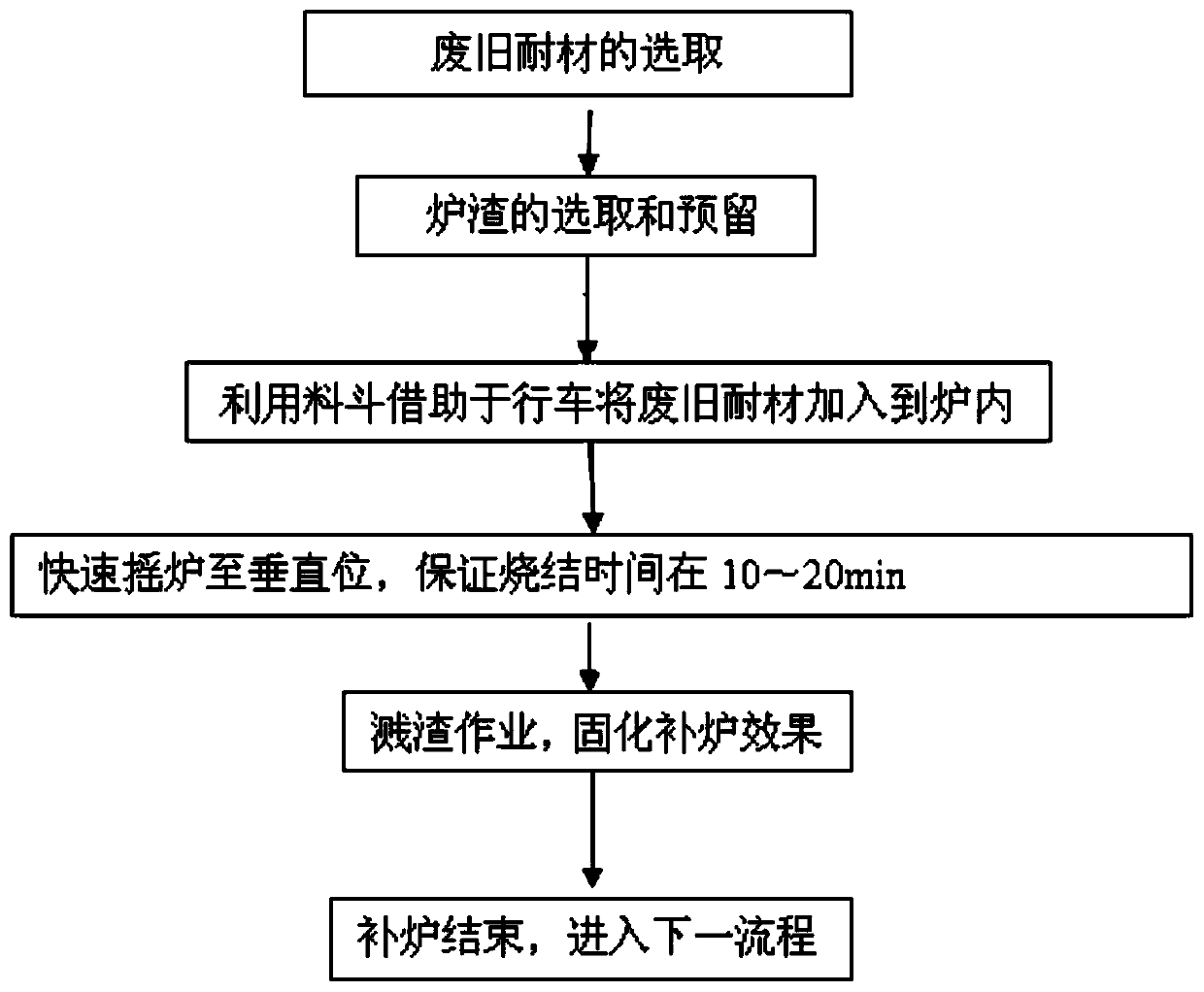

[0026] A method for protecting a converter with shaped refractory materials provided in this embodiment, such as figure 1 As shown, in this method, after the steel tapping of the converter is completed, the slag is left in the furnace according to the amount of slag and the amount of shaped refractory material required, and the waste brick or magnesite is added to promote the rapid cooling and bonding of the slag. The temperature difference between the slag and the lining interface, through the mutual diffusion of minerals, makes the slag and the lining a whole to achieve the effect of repairing the furnace.

[0027] In this example, the bottom position of the 3# converter lining of the No. The regional thickness of 700mm, which is lower than the target control value, is not conducive to the normal organization of on-site production and affects the safety of the furnace condition. According to this method, the bottom of the furnace has fallen faster. Now use this method to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com