Limestone powder porous cement concrete material for dock chamber bottom plate drainage cushion layer and preparation method thereof

A technology of cement concrete and limestone powder, which is applied in application, household appliances, ceramic products, etc., can solve the problems of high maintenance cost, large impact on erosion, short service life, etc., and achieves enhanced mechanical properties, reduced cement consumption, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

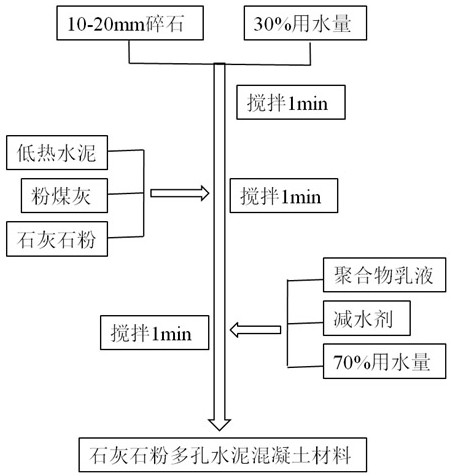

Image

Examples

Embodiment 1

[0036] The cement is Gezhouba Shimen P•LH42.5 low-heat cement, with a compressive strength of 46.1MPa at 28 days; the fly ash is F II grade fly ash of Hainan Dongfang Power Plant, with a fineness of 15%, a water demand ratio of 97%, and an activity of 77% at 28 days; The limestone powder is Hainan Lingshui limestone powder, 45μm square hole sieve 19%, calcium carbonate content 82%, 7d compressive strength ratio 64%, 28d compressive strength ratio 70%; polymer emulsion is Suzhou Institute of Building Research Co., Ltd. The SJ type milky white liquid produced by the company has a solid content of 50% and a density of 1.07g / cm 3 , pH value 5; the crushed stone is Hainan Tiefugang crushed stone, 10-20mm continuous gradation, crushing value 10.8%; the water reducer is high performance polycarboxylate water reducer, the solid content is 10%, 23%; water is tap water.

[0037] A preparation method for the limestone powder porous cement concrete material used for the drainage cushion ...

Embodiment 2

[0045]The cement is Gezhouba Shimen P•LH42.5 low-heat cement, with a compressive strength of 46.1MPa at 28 days; the fly ash is F II grade fly ash of Hainan Dongfang Power Plant, with a fineness of 15%, a water demand ratio of 97%, and an activity of 77% at 28 days; The limestone powder is Hainan Lingshui limestone powder, 45μm square hole sieve 19%, calcium carbonate content 82%, 7d compressive strength ratio 64%, 28d compressive strength ratio 70%; polymer emulsion is Suzhou Institute of Building Research Co., Ltd. The SJ type milky white liquid produced by the company has a solid content of 50% and a density of 1.07g / cm 3 , pH value 5; the crushed stone is Hainan Tiefugang crushed stone, 10-20mm continuous gradation, crushing value 10.8%; the water reducer is high performance polycarboxylate water reducer, the solid content is 10%, 23%; water is tap water.

[0046] A preparation method for the limestone powder porous cement concrete material used for the drainage cushion o...

Embodiment 3

[0054] The cement is Gezhouba Shimen P•LH42.5 low-heat cement, with a compressive strength of 46.1MPa at 28 days; the fly ash is F II grade fly ash of Hainan Dongfang Power Plant, with a fineness of 15%, a water demand ratio of 97%, and an activity of 77% at 28 days; The limestone powder is Hainan Lingshui limestone powder, 45μm square hole sieve 19%, calcium carbonate content 82%, 7d compressive strength ratio 64%, 28d compressive strength ratio 70%; polymer emulsion is Suzhou Institute of Building Research Co., Ltd. The SJ type milky white liquid produced by the company has a solid content of 50% and a density of 1.07g / cm 3 , pH value 5; the crushed stone is Hainan Tiefugang crushed stone, 10-20mm continuous gradation, crushing value 10.8%; the water reducer is high performance polycarboxylate water reducer, the solid content is 10%, 23%; water is tap water.

[0055] A preparation method for the limestone powder porous cement concrete material used for the drainage cushion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com