Pipeline potential monitoring device and method for synchronously monitoring potentials in different areas of pipeline

A potential monitoring and pipeline technology, which is applied in the field of corrosion monitoring and detection, can solve the problems of inconvenient installation and use, inability to collect pipeline potential data intensively, and difficulty in realizing potential measurement, etc., and achieve the effect of convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is further described below in conjunction with embodiment.

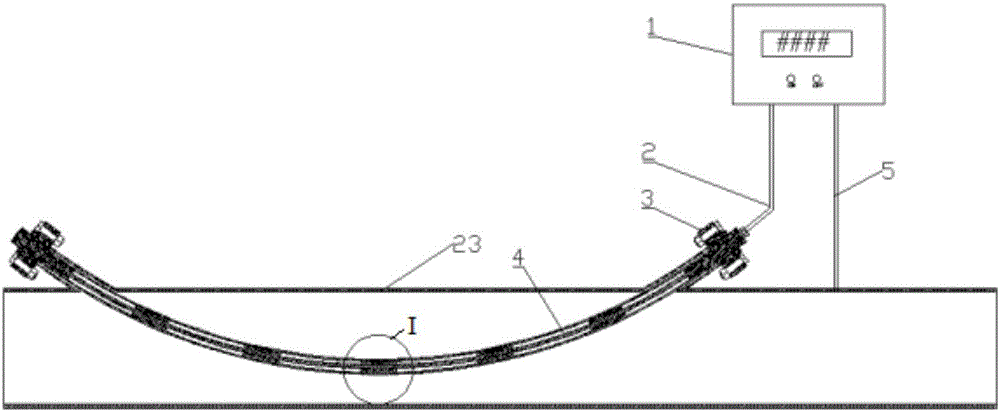

[0044] Such as figure 1 As shown, a pipeline potential monitoring device of the present invention includes a multi-channel potential collector 1 , a linear reference electrode 4 and a mounting flange 3 .

[0045] Wherein, the linear reference electrode 4 is installed inside the pipe to be measured 23 through the mounting flanges 3 provided at its two ends; the linear reference electrode 4 is connected with the multi-channel potential collector 1 through the multi-core shielded cable 2; The reference ground end of the channel potential collector 1 is connected to the pipeline 23 to be tested through a reference ground cable 5 .

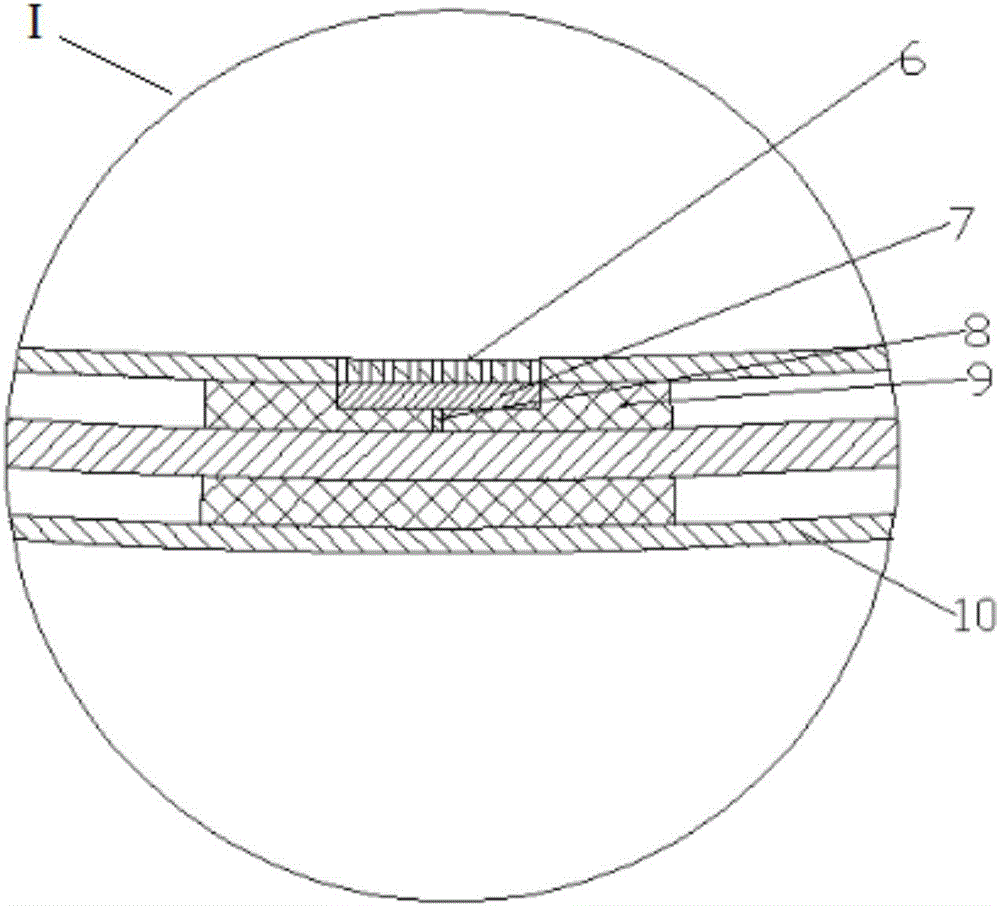

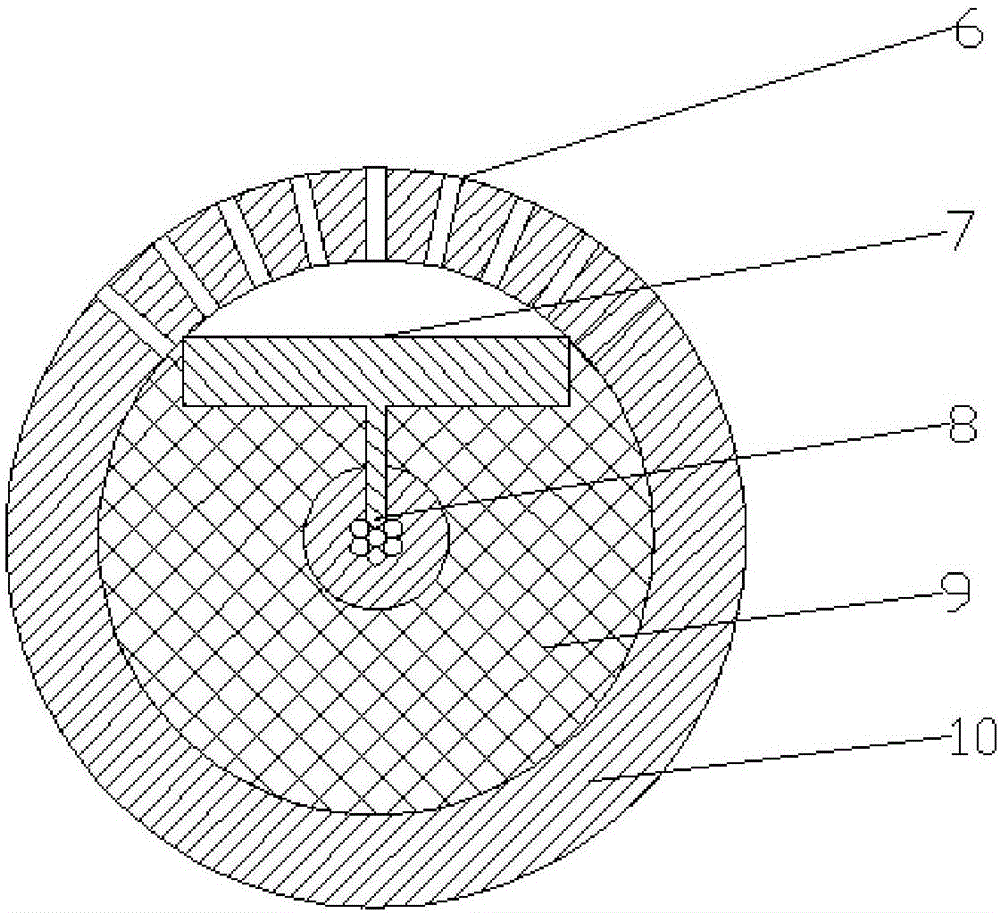

[0046] The linear reference electrode 4 is a linear array structure, including a plurality of uniformly distributed reference electrode units. The number and spacing of the reference electrode units are designed according to the area to be monitored in the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com