Compressor rotor blade meeting both pneumatic and strength requirements

A compressor rotor and blade technology, which is applied in the field of aerodynamic design of turbomachinery, can solve the problems of blade aerodynamic performance and strength at the same time, and achieve the effect of expanding the stable working range, good practical application value, and continuous curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

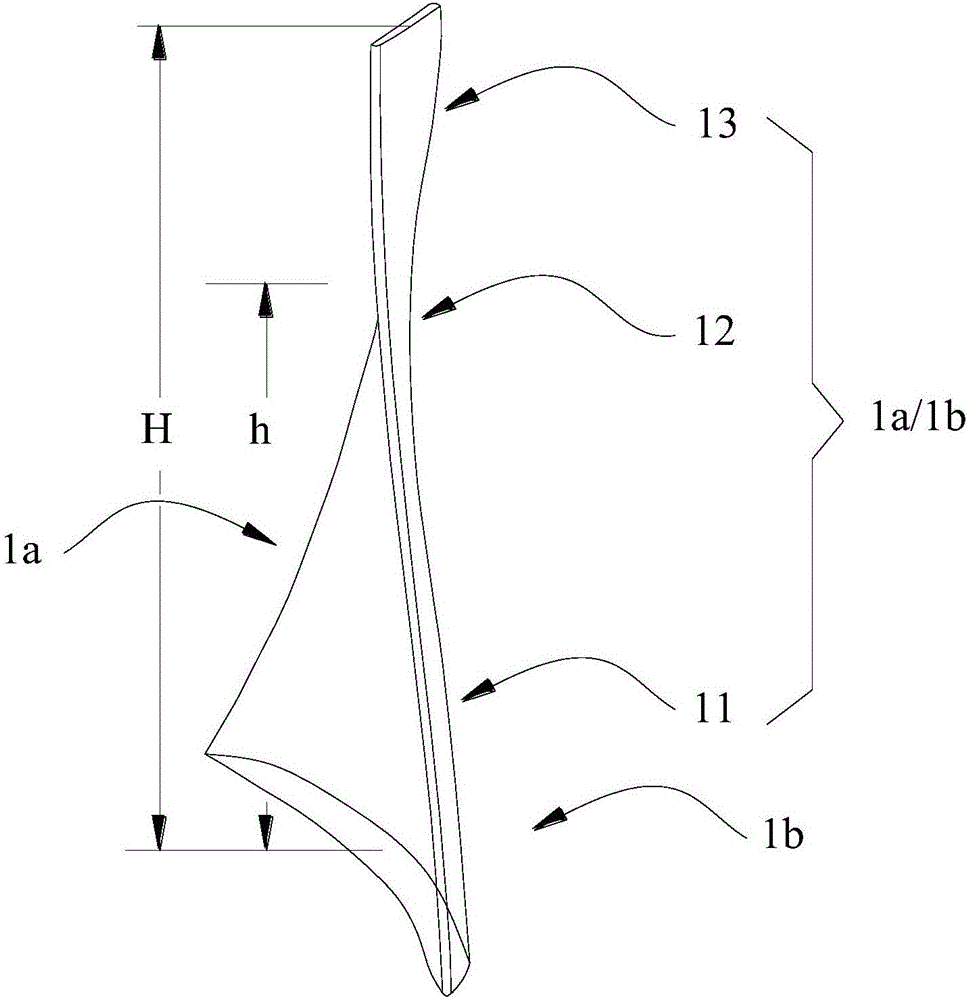

[0019] see figure 1 , the present invention provides a compressor rotor blade structure that takes into account both aerodynamics and strength. Half leaf 11, middle portion 12, and upper half leaf 13; the inner curved surface 1a is concave, and its concave degree gradually decreases from bottom to top; the outer curved surface 1b is convex, and its convex degree is from It gradually decreases from bottom to top; the curvature of the cross section of the middle part 12 is zero.

[0020] In the present invention, the inner curved surface 1a faces the air outlet, and the outer curved surface 1b is located on the side of the air inlet, and the height h of the lower half blade 11 accounts for 40-90% of the blade height H. Further, the cross-section of the blade along the length direction adopts the center-of-gravity stacking structure to construct a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com