Turbine movable blade pressure surface and top compound angle film hole layout structure

A technology of layout structure and compound angle, applied in the directions of engine components, machines/engines, blade support components, etc., can solve the problems of the influence of the mainstream aerodynamic performance on the blade surface, the complex air film hole structure, and the increase of aerodynamic losses, so as to increase the air flow rate. Membrane coverage area, overcoming adverse effects, reducing the effect of aerodynamic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, further detailed description will be given below with reference to the accompanying drawings.

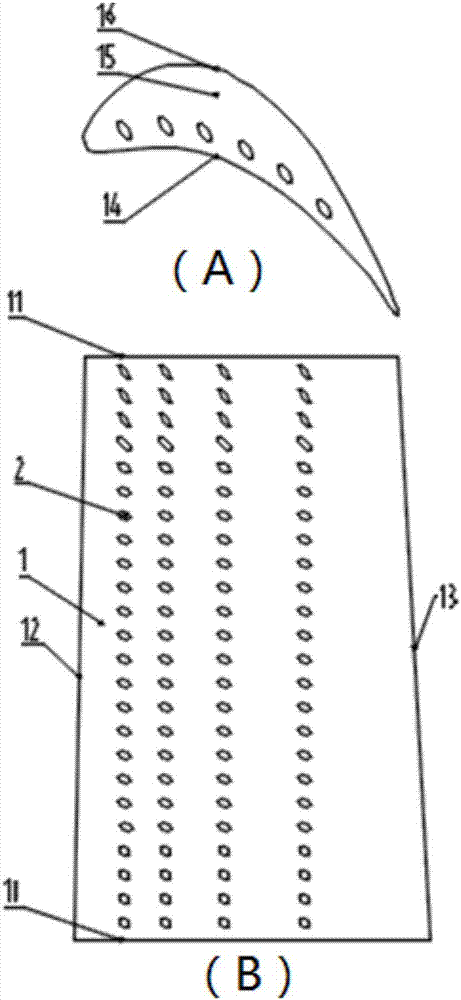

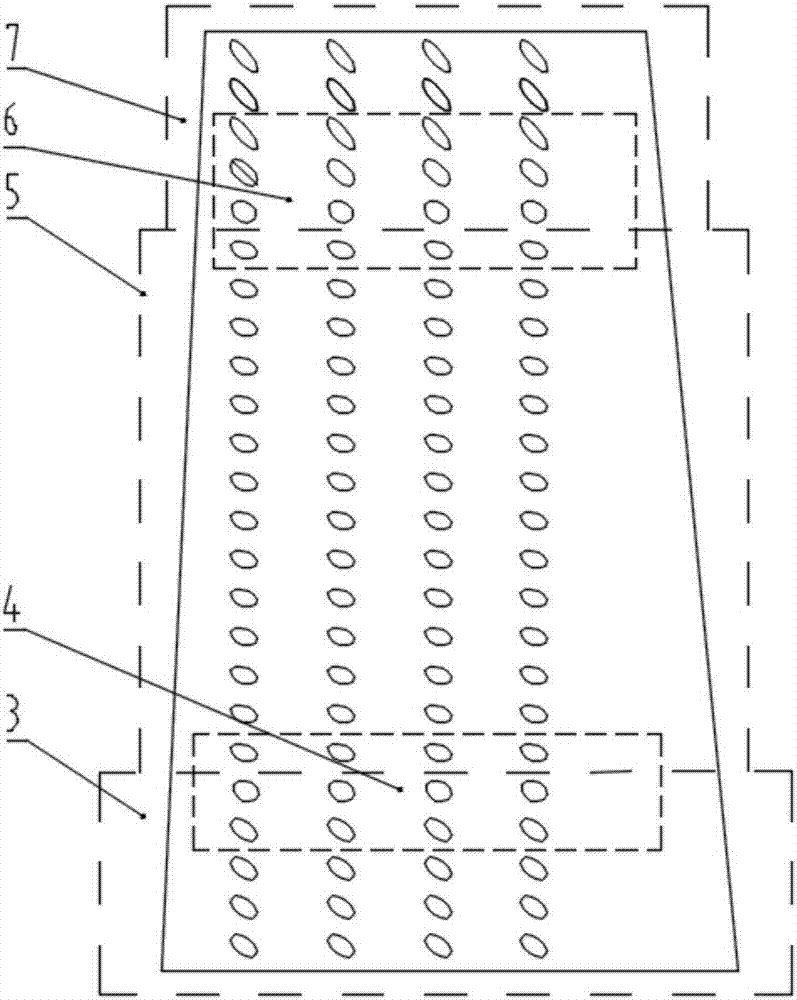

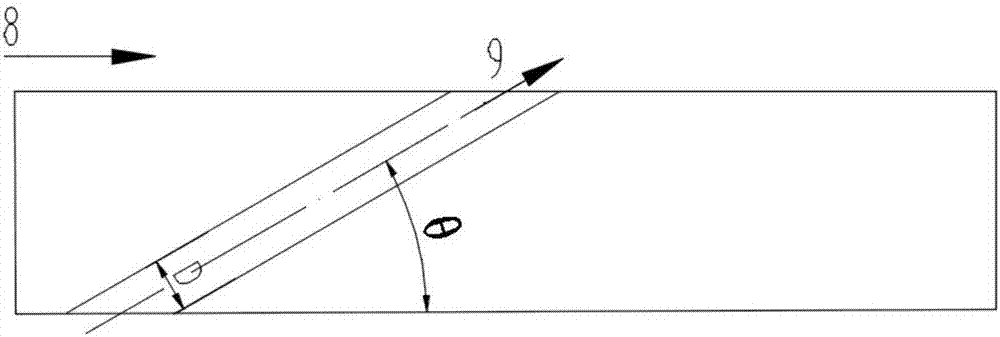

[0050] Such as figure 1Shown, the present invention is applicable to the compound angle film hole layout structure of aero-engine turbine blade pressure surface and top, turbine blade 1 comprises blade root 10, blade tip 11, leading edge 12 and trailing edge 13, turbine blade The pressure surface 14 of 1 is provided with 4 rows of compound corneum holes 2 arranged in parallel along the entire spanwise area from the blade root to the blade tip, and the top 15 of the turbine rotor blade 1 is provided with a row of compound corneum holes 2. The membrane hole 2 is in communication with the cooling air flow chamber inside the turbine blade 1 . The first row of holes is located at 0.12 times the chord length, the second row of holes is located at 0.25 times the chord length, the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com