A Smart Integrated Monitor for Pressure Flow of Air Source System

A system pressure and comprehensive monitoring technology, applied in the direction of fluid pressure control, control/regulation system, electric fluid pressure control, etc., can solve the problem of limiting the flexibility and reliability of gas source system detection work, detection data, accuracy and detection Problems such as method differences and low efficiency of gas source system detection work can be achieved to improve operating efficiency and detection accuracy, improve flexibility and reliability, and use flexibility and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

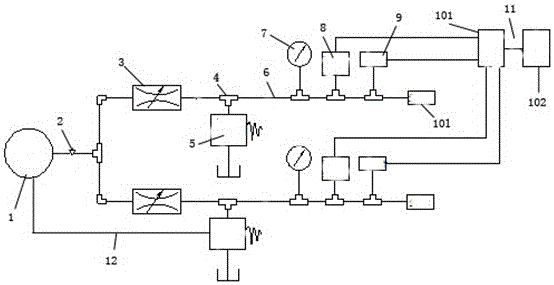

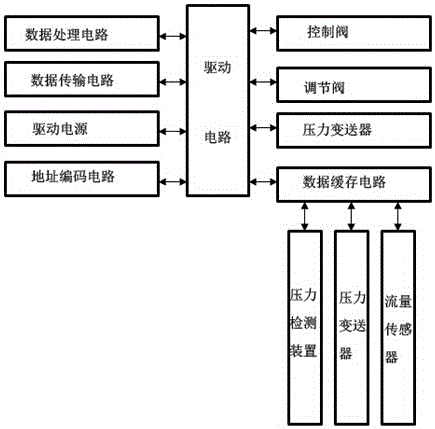

[0013] Such as figure 1 with 2 A gas source system pressure and flow intelligent comprehensive monitor is shown, including a simulated gas source 1, a control valve 2, a pressure reducer 3, a regulating valve 4, an overflow valve 5, a diversion tube 6, a pressure detection device 7, a pressure variable transmitter 8, flow sensor 9, simulated load 10, and control system 11. The simulated air source 1 is connected to the test pipeline through the control valve 2. There are at least two test pipelines. Each test pipeline is connected in parallel with each other, and each test pipeline The pipelines are all connected to at least one simulated load 10, and the test pipelines include a guide tube 6, a pressure reducer 3, a control valve 2, a relief valve 4, a pressure detection device 7, a pressure transmitter 8 and a flow sensor 9, wherein The pressure reducer 3 communicates with the control valve 2, the overflow valve 5 and the pressure detection device 7 respectively through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com