Adjustable mulching film perforating machine

A punching machine and adjustable technology, applied in the field of agricultural machinery, can solve the problems of low efficiency, high labor intensity, non-adjustable hole spacing, etc., and achieve the effects of convenient adjustment, meeting planting needs and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

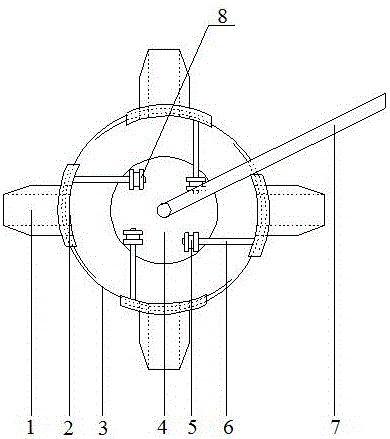

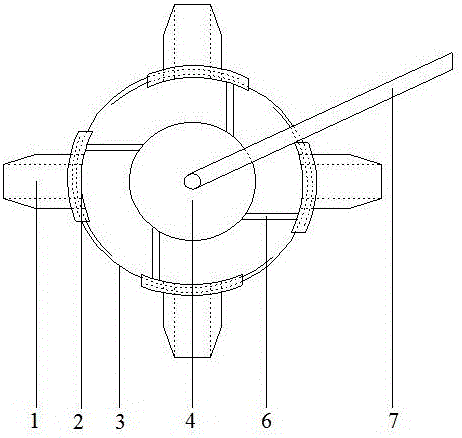

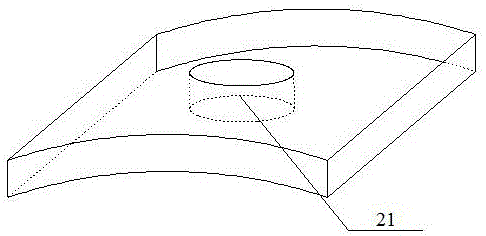

[0019] Such as figure 1 , 2 , A kind of adjustable mulch punching machine shown in 3, 4, comprises punching wheel and support frame 7, and punching wheel is connected with support frame 7 shafts, and punching wheel comprises punching cutter head 1, fixed piece 2, The web 4, the screw rod 6 and the rim, the punching cutter head 1 is fixedly connected with the fixed piece 2, and is socketed with the rim at the same time; the rim is composed of at least two wheel pieces 3, and the middle part of the wheel piece 3 is provided with a hole 31, and its The width is consistent with the outer diameter of the perforating cutter head 1, and the adjacent wheels 3 are connected end to end; at least two fixing rings 5 are arranged on the web 4, which are connected to the screw 6 through a nut 8, and the other end of the screw 6 is connected to the fixing piece. 2 fixed connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com