Fertilizer placement drill

A fertiliser and controller technology, applied in fertilizer distributors, fertilization devices, direct liquid fertilizer conveying systems, etc., can solve the problems of high labor intensity, inconvenient operation, insufficient durability, etc., and achieve reduced labor intensity and fast fertilization. , the effect of not wasting fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

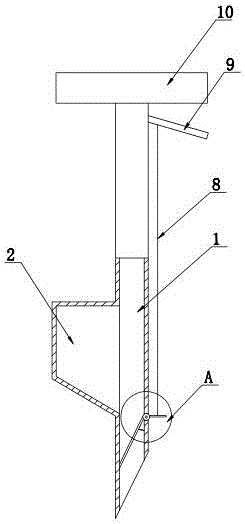

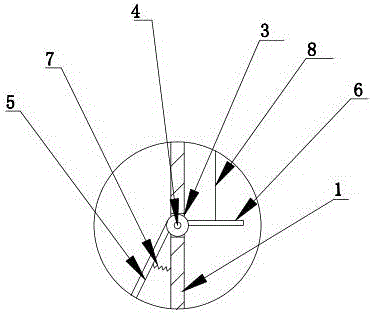

[0014] figure 1 , figure 2 Shown is a top dressing device provided by the present invention, including a cylinder 1 and a hopper 2; the hopper 2 is connected to the cylinder 1, and the outlet of the hopper 2 communicates with the cylinder 1; the cylinder 1 There is a mounting hole 3 on the top, and a rotating shaft 4 is installed in the mounting hole 3. The outer surface of the rotating shaft 4 fits around the mounting hole 3, and a baffle 5 and a fixed plate 6 are installed on the rotating shaft 4. The baffle 5 and the fixed plate 6 are fixedly installed on the rotating shaft 4; the baffle 5 is located in the cylinder 1, and a compression spring 7 is arranged between the baffle 5 and the inner wall of the cylinder 1; the fixed plate 6 is located in the cylinder 1 In addition, through the operation of the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com