Knee joint load-bearing power assisting exoskeleton device and working method thereof

A knee joint and exoskeleton technology, applied in the manufacture of tools, appliances to help people walk, manipulators, etc., can solve the problems of large structural errors, complex structures, and large volumes, and achieve small structural errors, small volume, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned features and advantages of the present invention more obvious and easy to understand, the following specific embodiments are given and the accompanying drawings are described in detail as follows.

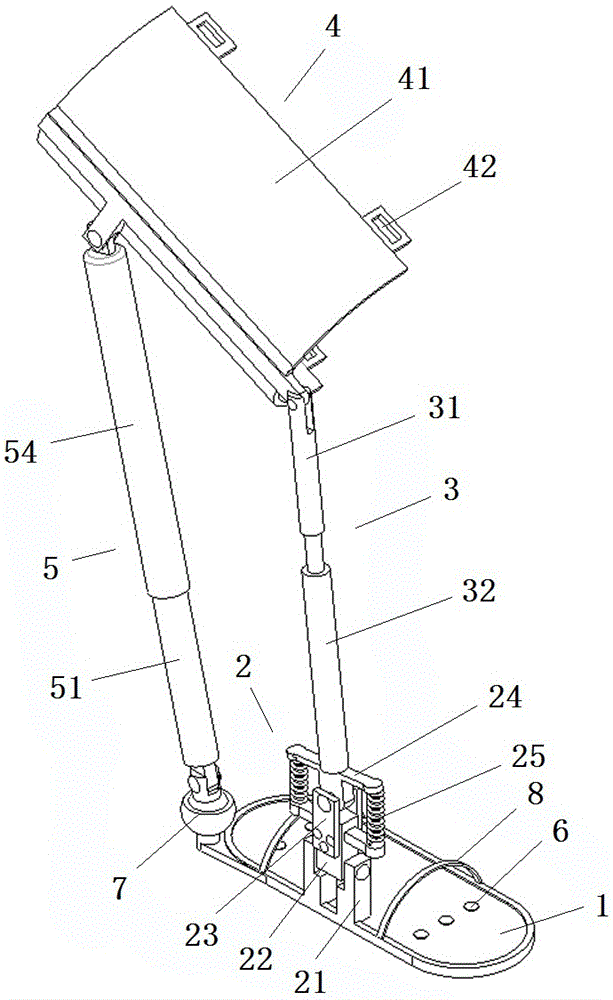

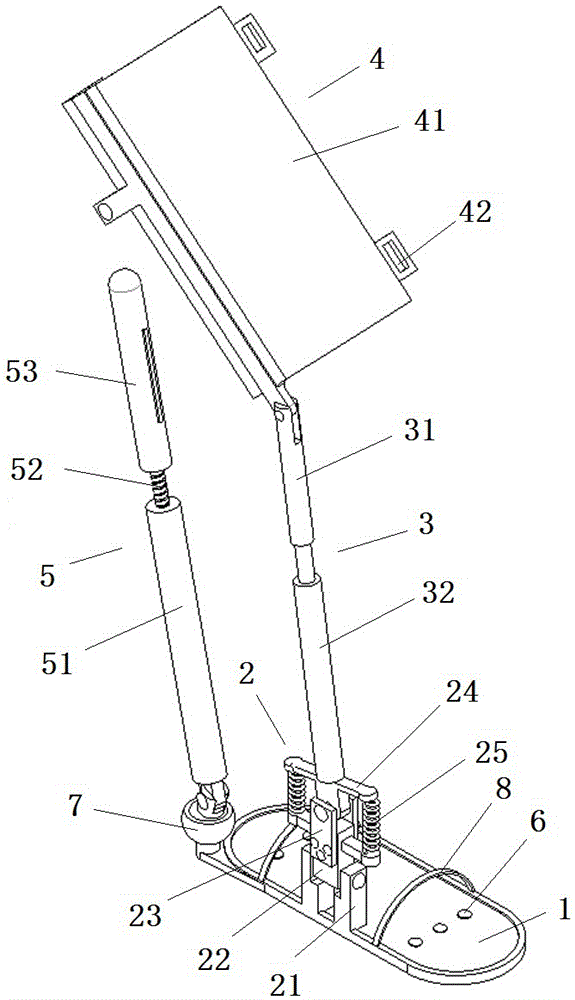

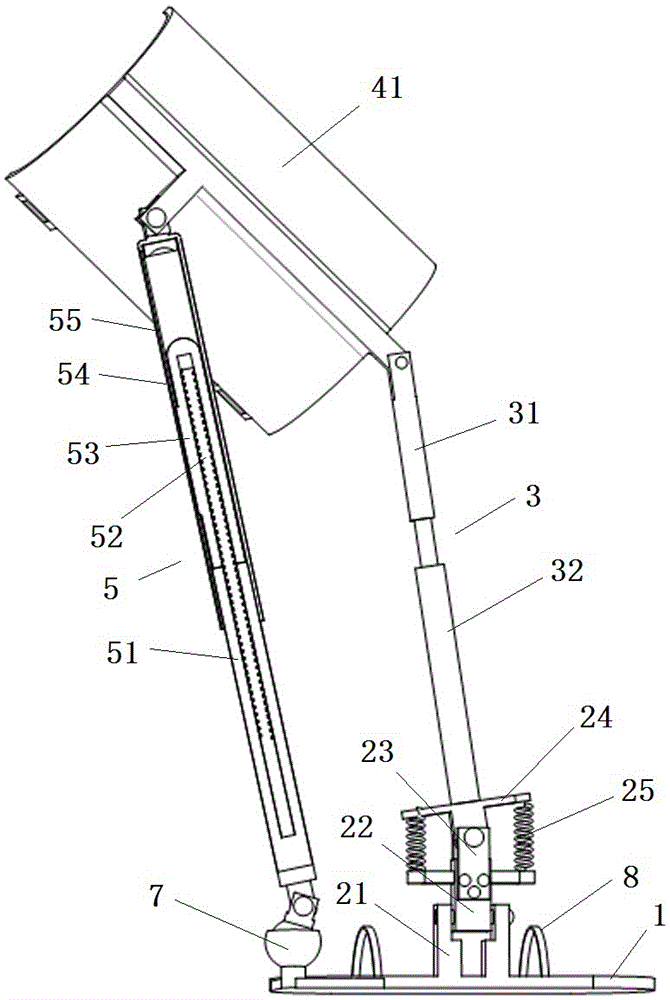

[0024] like Figures 1~4 As shown, a knee joint weight-bearing exoskeleton device includes a sole plate 1, an ankle joint 2 is provided at the outer end of the sole plate 1, and the ankle joint 2 is hinged with a calf rod 3, and the calf rod 3 is hinged with the thigh rod 4, and a servo electric cylinder assembly 5 that drives the movement of the thigh rod 4 is hinged between the rear end of the foot bottom plate 1 and the thigh rod 4, and the foot bottom plate 1 is arranged with several The pressure sensor 6 is electrically connected with the control module, and the control module is electrically connected with the servo electric cylinder assembly 5 .

[0025] In the embodiment of the present invention, the servo electric cylinder assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com