Automatic auxiliary material pasting device

An automatic sticking and auxiliary material technology, applied in the field of auxiliary material automatic sticking devices, can solve the problems of difficult alignment of auxiliary materials and product frames, limited continuous production capacity, and difficulty in guaranteeing product quality, so as to reduce manual intervention in the lamination process, The effect of reducing exposure time and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

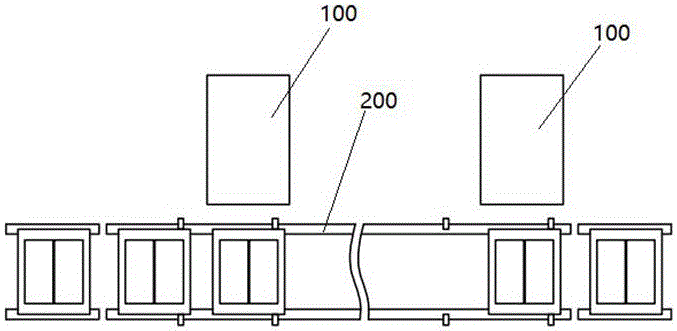

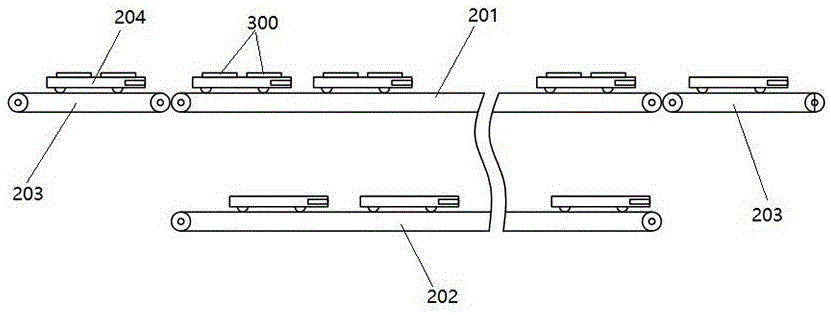

[0026] See figure 1 , an auxiliary material automatic sticking device, including an auxiliary material adsorption device 100 and a product delivery device 200, the number of auxiliary material adsorption devices 100 is determined according to the number of auxiliary materials to be bonded to the product and the number of process steps.

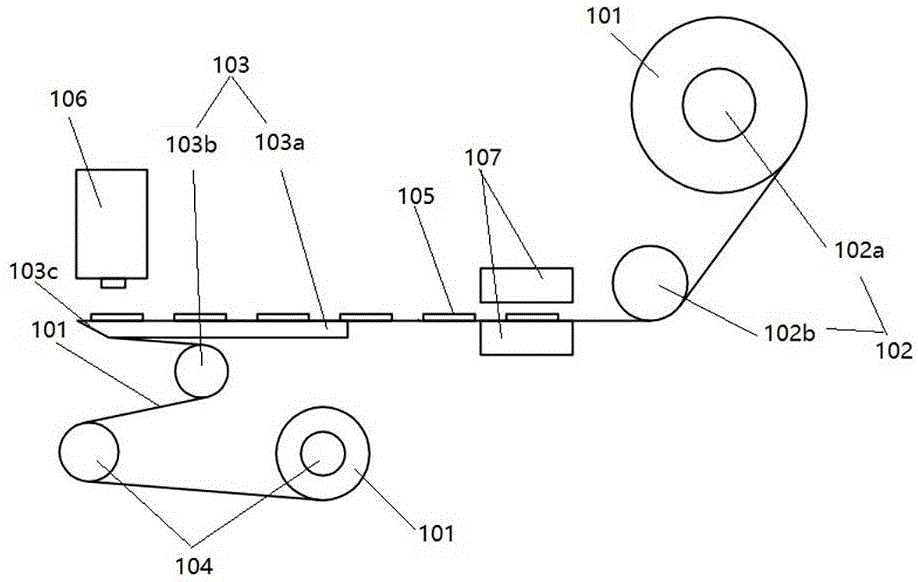

[0027] See figure 2 , wherein the auxiliary material adsorption device 100 includes:

[0028] The unwinding mechanism 102 for carrying the release paper roll 101 with the auxiliary material 105, the release paper 101 with the auxiliary material 105 is stored in a roll shape, so it is convenient to take out the release paper, the unwinding mechanism 102 includes several The unwinding rollers 102a, 102b are arranged in parallel, and the release paper 101 goes around the surfaces of these unwinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com