A stable transport chain for rod-shaped workpieces

A workpiece and rod-shaped technology, applied in the field of conveying chains for rod-shaped workpieces, can solve the problems of poor stability and low chain structure strength, and achieve the effects of good adaptability, prevention of detachment, and avoidance of chain plate deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

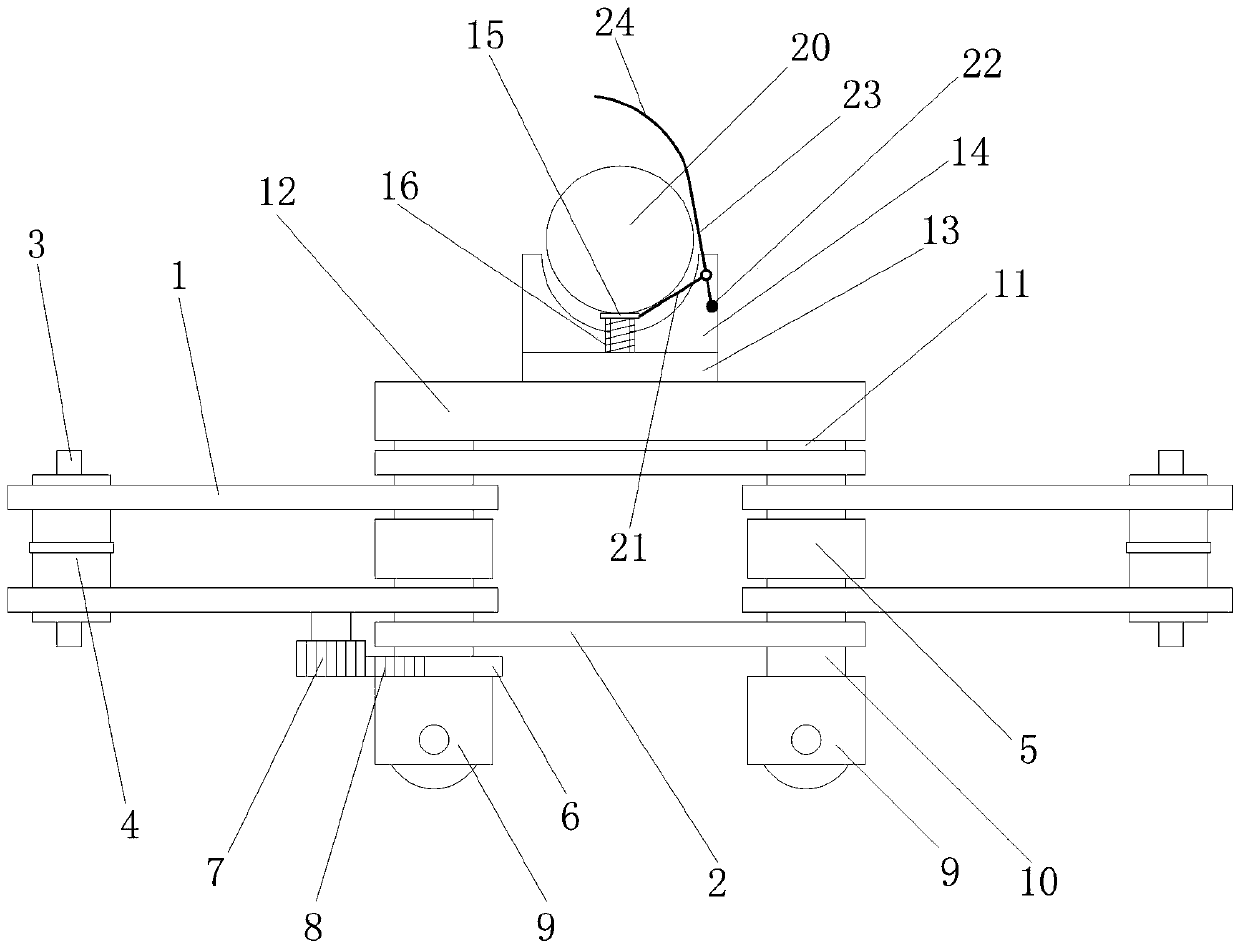

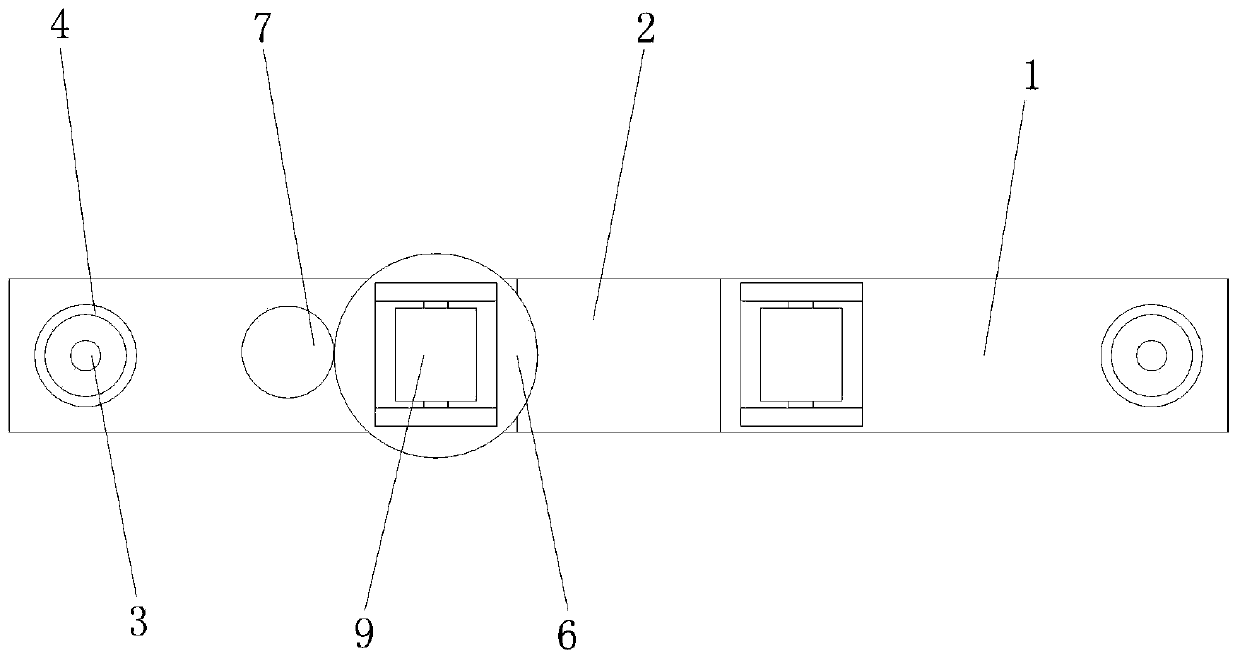

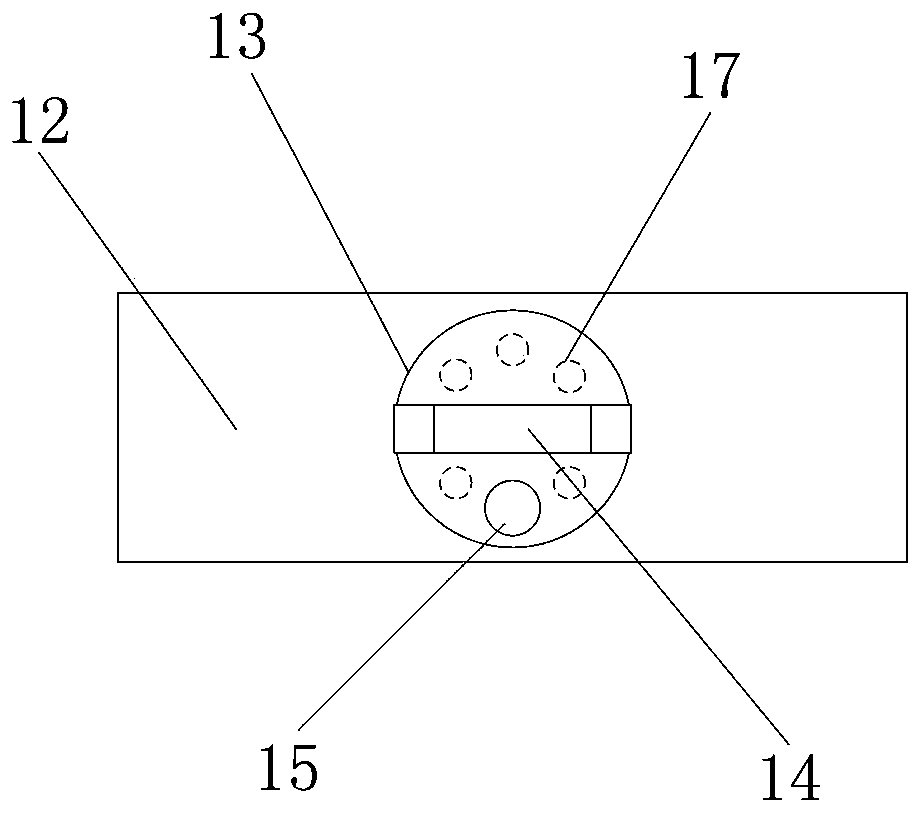

[0042] Such as Figure 1-4 As shown, a stable transport chain for rod-shaped workpieces provided by the present invention is formed by linking each chain link sequentially; each chain link includes two inner chain plates 1, two outer chain plates 2, two rollers 5, two A sleeve 4, two bearing pins 3, a support plate 12, two support wheels 9 and a blocking mechanism;

[0043] The two inner chain plates 1 are arranged parallel to each other up and down;

[0044] The two sleeves 4 are arranged in parallel on the two inner chain plates 1, and the two ends of the sleeves 4 pass through the two inner chain plates 1 to form anti-friction collars on the outside of the two inner chain plates 1, On the outer circumference of the sleeve 4, there is a limit convex ring, which can effectively reduce the friction between the outer chain plate 2 and the inner chain plate 1 by using the anti-friction convex ring, and prevent the outer chain plate 2 and the inner chain plate after long-term us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com