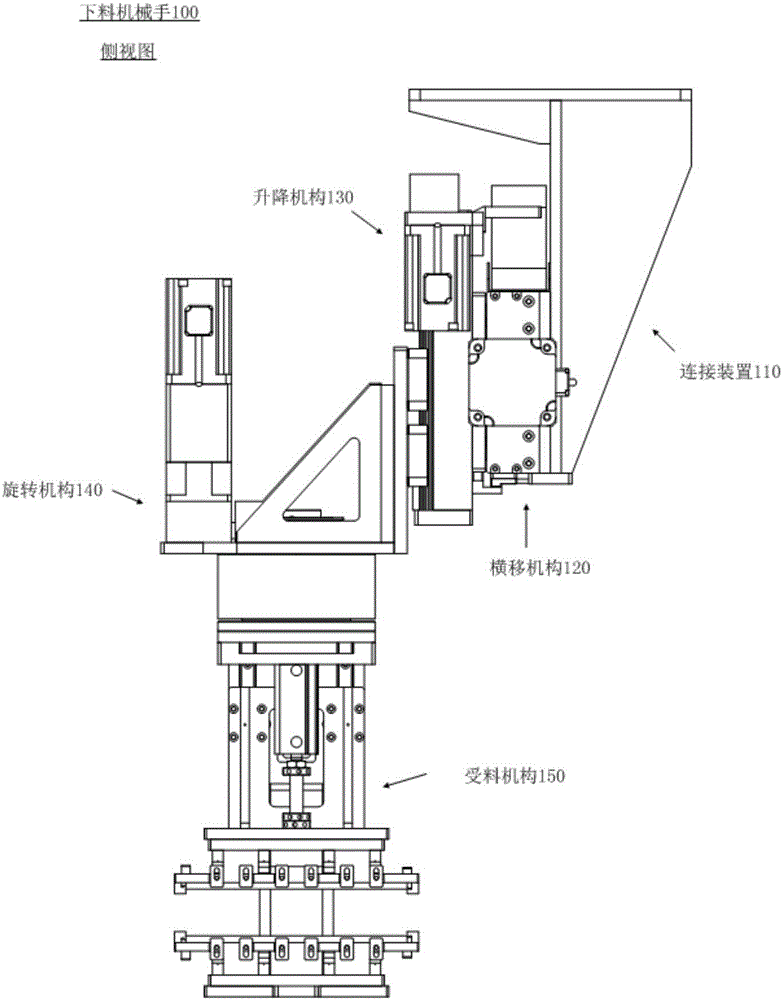

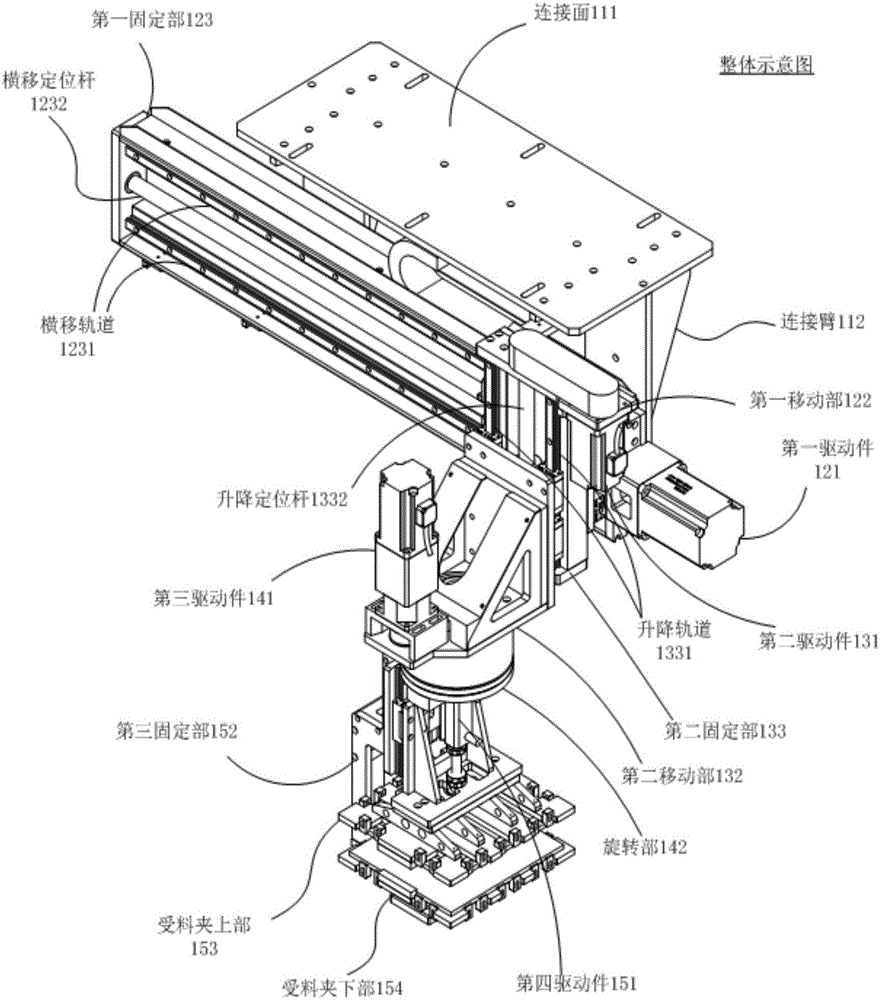

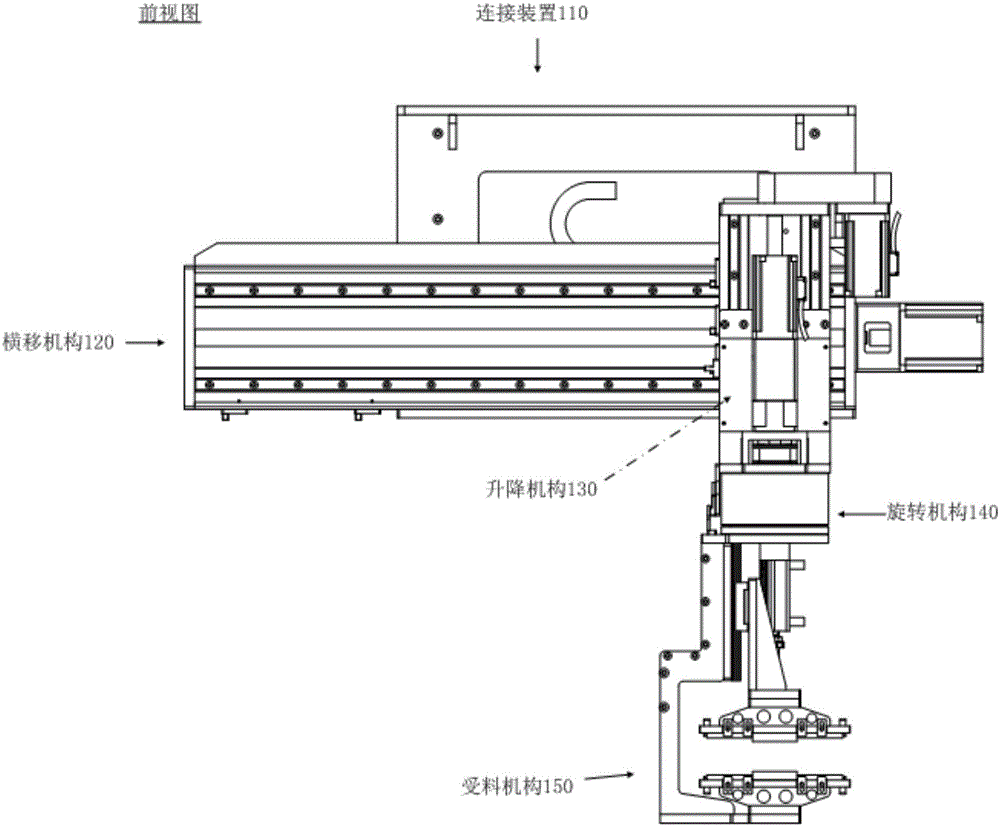

Discharging mechanical arm and discharging method thereof

A manipulator and blanking technology, which is applied to conveyor objects, sustainable manufacturing/processing, electrochemical generators, etc. Efficiency and solving the effect of large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The stacking machine generally consists of ten mechanisms: discharging mechanism, positive electrode material box, negative electrode material box, positive electrode secondary positioning mechanism, negative electrode secondary positioning mechanism, positive electrode feeding mechanism, negative electrode feeding mechanism, stacking table, material receiving Mechanism, gluing mechanism, unloading manipulator and discharging mechanism. The working principle of the laminator is to put the positive and negative poles into the material box, and the manipulator moves left and right to pick up the poles in the positive and negative material boxes. After secondary positioning, the positive and negative poles are placed on the stacking table alternately. . The diaphragm unwinds automatically, and the lamination table drives the diaphragm to move back and forth to form a Z-shaped winding. After the lamination is completed, it is cut according to the set length, and the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com