A kind of polyurethane elastomer composite material and preparation method thereof, preparation and application of polyurethane elastomer

A polyurethane elastomer and combined material technology, applied in the field of polyurethane elastomer, can solve the problems of not being able to improve the elasticity of fitness equipment and not being environmentally friendly, and achieve the effects of shortening demoulding time and curing time, high production efficiency, and realizing room temperature curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

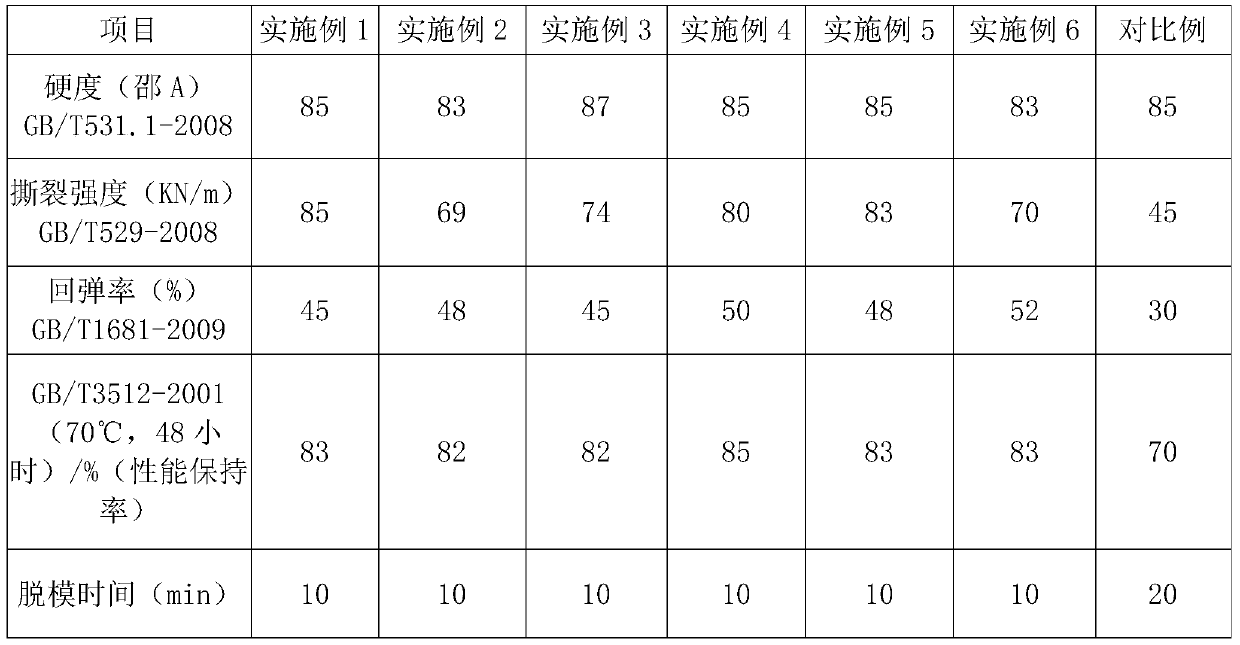

Examples

Embodiment 1

[0040] Curing agent components: GEP-560S 75%, Uric H-30 2%, HLBH-P 2000 3%, 3,5-dimethylthiotoluenediamine 20%, composed of bismuth isooctanoate and zinc isooctanoate The mixed catalyst 2‰ (the content of bismuth in bismuth isooctanoate is 18%, and the content of zinc in zinc isooctanoate is 22%) is mixed and then dehydrated at 100°C and below -0.1MPa to a water content of ≤500ppm to obtain a curing agent component.

[0041] Prepolymer component: take 54% of DL-1000 polyether polyol and 46% of MDI-50, and react at 75°C for 3 hours to obtain a prepolymer with an isocyanate content of 11%.

[0042] Mix the prepolymer and curing agent components in a mass ratio of 100:100. The temperature of the prepolymer is 45°C, the temperature of the curing agent is 45°C, the mold temperature is 90°C, and the mold is demolded in 10 minutes. The product is vulcanized at room temperature for 72 hours to obtain Shao A85 polyurethane elastomer.

Embodiment 2

[0044] Curing agent components: EP-330N 65%, Uric H-30 2%, HLBH-P 3000 3%, 3,5-dimethylthiotoluenediamine 30%, composed of bismuth isooctanoate and zinc isooctanoate The mixed catalyst 2‰ (the content of bismuth in bismuth isooctanoate is 18%, and the content of zinc in zinc isooctanoate is 22%) is mixed and then dehydrated at 100°C and below -0.1MPa to a water content of ≤500ppm to obtain a curing agent component.

[0045] Prepolymer component: take 54% of DL-1000 polyether polyol and 46% of MDI-50, and react at 75°C for 3 hours to obtain a prepolymer with an isocyanate content of 11%.

[0046] Mix the prepolymer and curing agent components in a mass ratio of 100:100. The temperature of the prepolymer is 45°C, the temperature of the curing agent is 45°C, the mold temperature is 90°C, and the mold is demolded in 10 minutes. The product is vulcanized at room temperature for 72 hours to obtain Shao A83 polyurethane elastomer.

Embodiment 3

[0048] Curing agent components: GEP-560S 75%, Uric H-30 2%, HLBH-P 2000 3%, methylene bis-o-chloroaniline 20%, mixed catalyst composed of bismuth isooctanoate and zinc isooctanoate 2‰ (Wherein, the content of bismuth in bismuth isooctanoate is 18%, and the content of zinc in zinc isooctanoate is 22%). After mixing, dehydrate at 100°C and below -0.1MPa until the water content is less than or equal to 500ppm to obtain the curing agent component.

[0049] Prepolymer component: take DL-2000 polyether polyol 60%, MDI-50 40%, react at 75°C for 3 hours to obtain a prepolymer with an isocyanate content of 11%.

[0050] Mix the prepolymer and curing agent components in a mass ratio of 100:100. The temperature of the prepolymer is 45°C, the temperature of the curing agent is 45°C, the mold temperature is 90°C, and the mold is demolded in 10 minutes. The product is vulcanized at room temperature for 72 hours to obtain Shao A87 polyurethane elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com