Preparation method of pure vegetable cleanser essence

A detergent and pure plant technology, applied in the field of preparation of pure plant detergent, can solve the problems of detergent stimulation, groundwater pollution, difficult rinsing, etc., and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

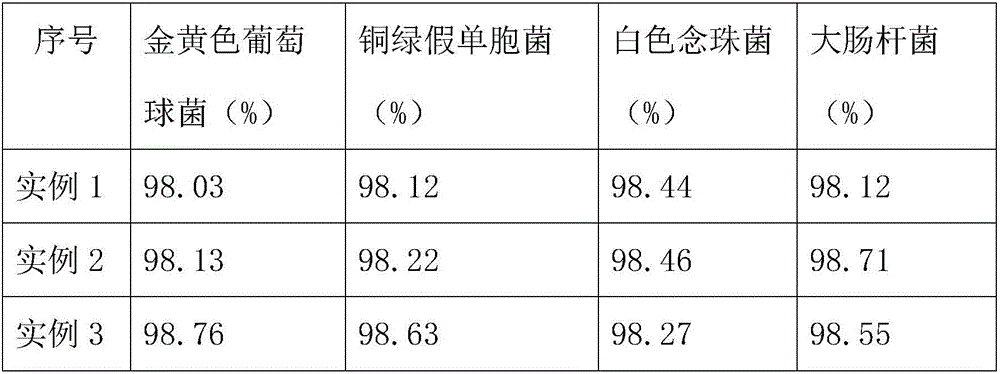

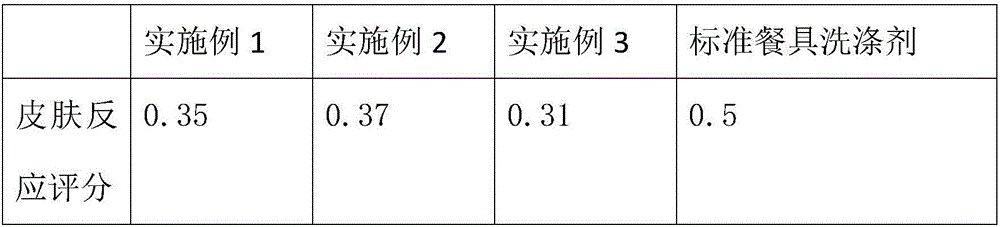

Examples

Embodiment 1

[0017] Embodiment 1: a kind of preparation method of pure plant detergent, it comprises the following steps: a, prepare oat extract; b, prepare nettle extract; powder; e, preparation of pure plant detergent;

[0018] a. Preparation of oat extract: Mix 1 part of oat grains with a mesh number of 1000 and 5 parts of drinking water with a pH of 6.5, heat at 900°C for 8 minutes, and then filter through two layers of filter cloth, the upper layer The filter cloth filter diameter is 1.5mm, and the filter cloth filter diameter of the lower layer is 0.5mm, and the filtrate obtained after filtering is cooled at -40°C for half an hour to obtain oat extract;

[0019] b. Preparation of nettle extract: Mix 1 part of nettle and 5 parts of drinking water with a pH value of 6.5 and heat at 900°C for 8 minutes, then filter through two layers of filter cloths, the filter cloth of the upper layer has a filter diameter of 1.5mm, the filter diameter of the lower filter cloth is 0.5mm, and the filt...

Embodiment 2

[0023] Embodiment 2: A kind of preparation method of pure plant detergent, it comprises the following steps: a, prepare oat extract; b, prepare nettle extract; powder; e, preparation of pure plant detergent;

[0024] a. Preparation of oat extract: Mix 1 part of oat grains with a mesh number of 1000 and 10 parts of drinking water with a pH of 6.5, heat at 1050°C for 8 minutes, and then filter through two layers of filter cloths, the upper filter cloth The cloth filter diameter is 1.5mm, and the lower filter cloth filter diameter is 0.5mm, and the filtrate obtained after filtering is cooled at -40°C for half an hour to obtain oat extract;

[0025] b. Preparation of nettle extract: mix 1 part of nettle with 10 parts of drinking water with a pH value of 6.5 and heat at 1050°C for 8 minutes, then filter through upper and lower layers of filter cloth, wherein the filter cloth diameter of the upper layer is 1.5mm, the filter diameter of the lower filter cloth is 0.5mm, and the filtr...

Embodiment 3

[0029] Embodiment 3: a kind of preparation method of pure plant detergent, it comprises the following steps: a, prepare oat extract; b, prepare nettle extract; powder; e, preparation of pure plant detergent;

[0030] a. Preparation of oat extract: Mix 1 part of oat grains with a mesh number of 1000 mesh and 18 parts of drinking water with a pH of 6.5, heat at 1200°C for 8 minutes, and then filter through two layers of filter cloths, the upper filter cloth The cloth filter diameter is 1.5 mm, and the filter cloth filter diameter of the lower layer is 0.5 mm. The filtrate obtained after filtration is cooled at -40°C for half an hour to obtain the oat extract;

[0031] b. Preparation of nettle extract: Mix 1 part of nettle with 18 parts of drinking water with a pH value of 6.5 and heat at 1200°C for 8 minutes, then filter through two layers of filter cloth, wherein the filter cloth diameter of the upper layer is 1.5mm, the filter diameter of the lower filter cloth is 0.5mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com