Production process for full-shading coating fabrics with matte surfaces

A production process, full shading technology, used in coatings, textiles and papermaking, etc., can solve the problem of high surface gloss and achieve the effect of reducing gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

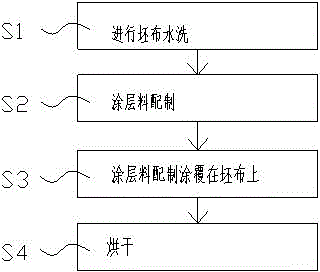

[0024] Such as figure 1 The production process of a full-shading coated fabric with a matte surface includes the following steps:

[0025] S1: washing gray cloth;

[0026] S2: Coating material preparation: The coating material includes 35-45 parts of large-particle-diameter resin, 10-20 parts of small-particle-diameter resin, 0.2-0.6 part of dispersant, and 0.1-0.5 part of defoamer in parts by weight , 0.5 to 3 parts of matting powder, 20 to 40 parts of titanium dioxide, 5 to 35 parts of filler, 0.1 to 0.8 parts of crosslinking agent and 0.5 to 2 parts of anti-sticking agent, and the particle size of the large particle diameter resin is 220nm to 300nm , the particle size of the small particle size resin is 90nm ~ 130nm, first mix and stir the large particle size resin, small particle size resin, dispersant defoamer, titanium dioxide, filler, crosslink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com