Torque control type nut and spanner special for same

A torque control and nut technology, applied in the direction of nuts, wrenches, screws, etc., can solve the problems of tensile permanent deformation of threads, loosening and damage of bolts, etc., and achieve the effect of solving tensile permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

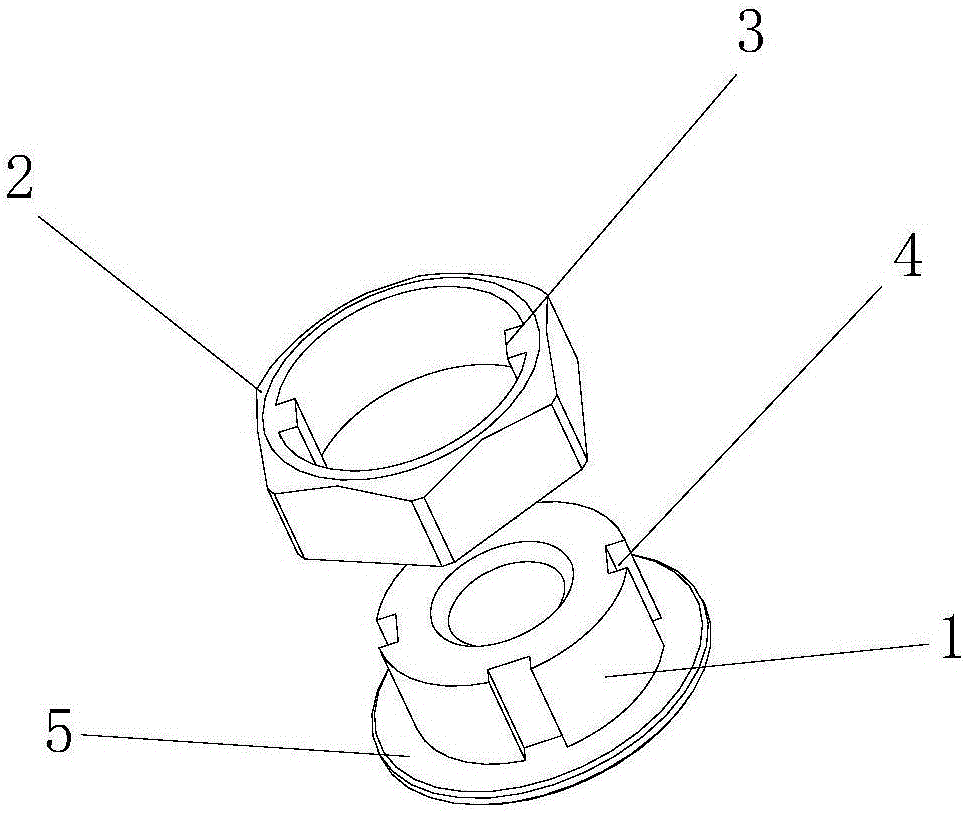

[0015] refer to figure 1 , a torque control nut, including a nut inner sleeve 1 made of low-carbon steel surface hot-dip galvanized material, a nut outer sleeve 2 sleeved outside the nut inner sleeve 1 and used to tighten the nut inner sleeve 1, The nut jacket 2 is a nut jacket made of POM material, wherein the outer edge of the cross section of the nut jacket 2 is a regular polygon, and the inner edge is a circular ring structure. The inner wall of the nut inner sleeve 1 has a thread structure, and the nut The outer edge of the cross section of the inner sleeve 1 is circular, the inner wall of the nut outer sleeve 2 is provided with two symmetrical first ribs 3 along the axial direction, and the outer wall of the nut inner sleeve 1 is provided with at least one pair to match the first ribs 3 The groove 4, the first rib 3 and the groove 4 are all arranged on the axis of the nut inner sleeve 1, and the first rib 3 is placed in the groove 4 respectively.

[0016] The nut outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com