Heat treatment pit furnace automatic production and supporting equipment

An automation device and pit furnace technology, applied in the field of heat treatment, can solve the problems of wasting energy, rushing to the top, bottom, collision, and difficult to control, etc., to achieve the effect of eliminating shaking, increasing speed, and reducing mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

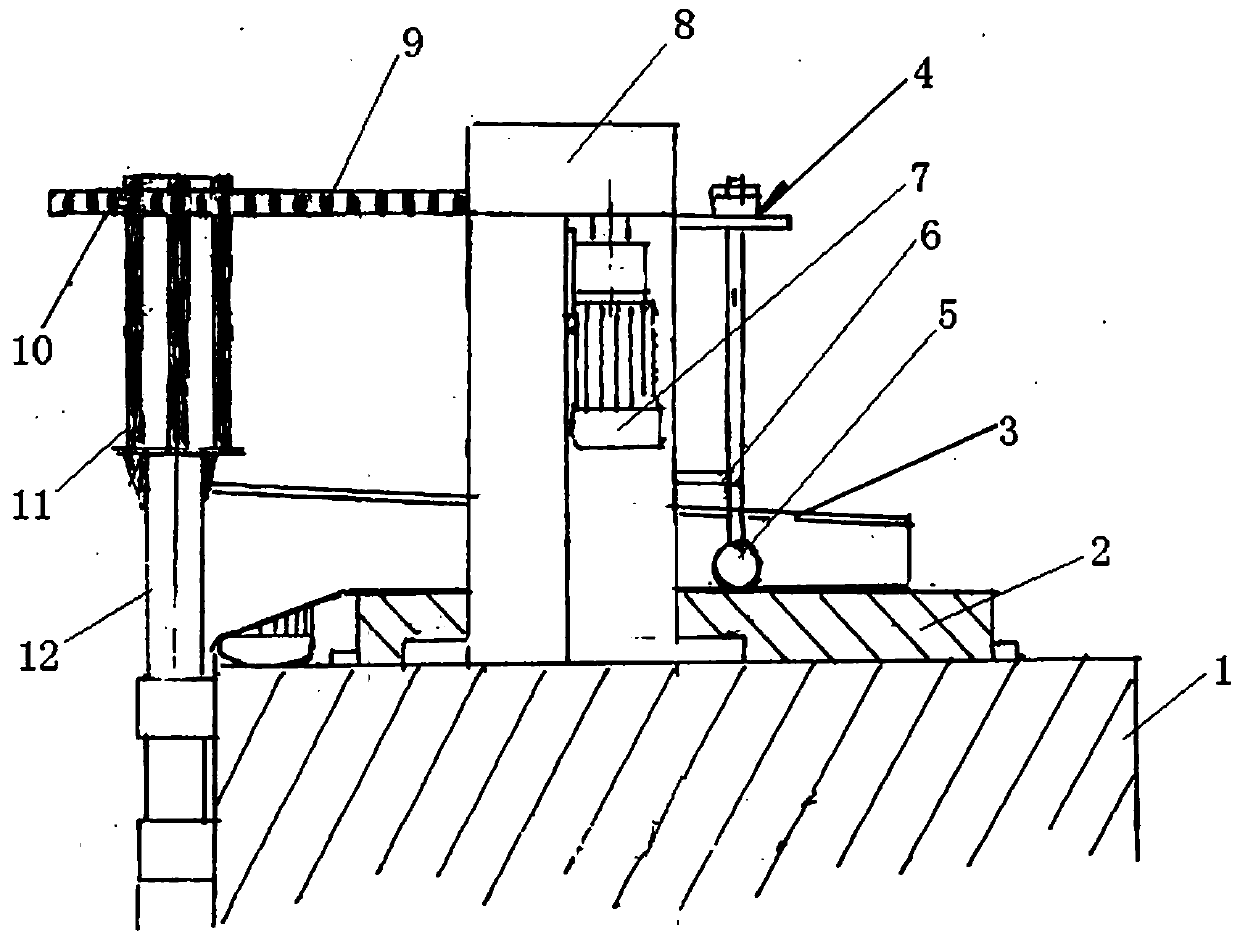

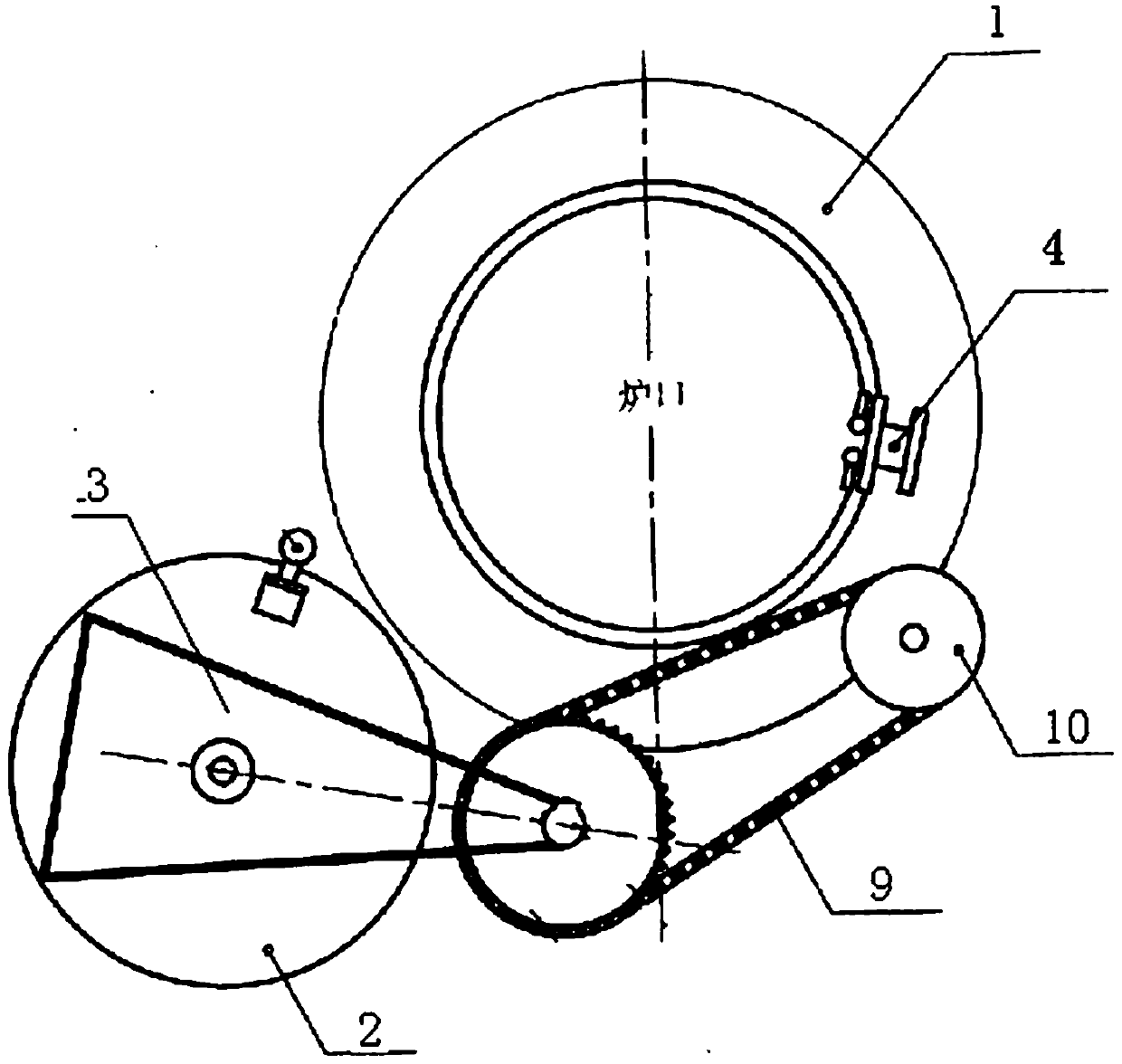

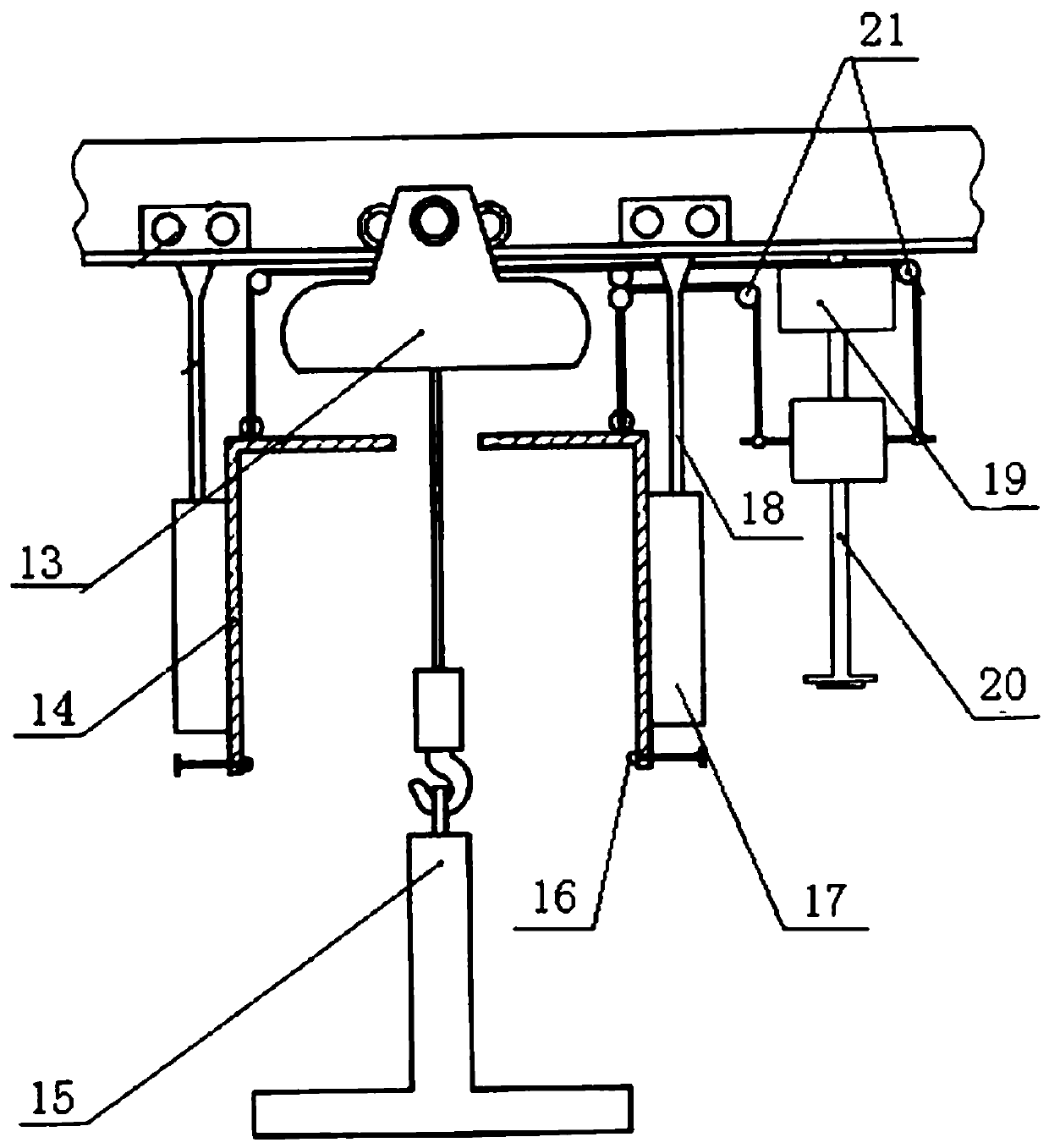

[0025] Heat treatment well-type furnace automatic production and supporting equipment, including well-type furnace cover automatic opening and closing device, well-type furnace hoisting tray moving shield locking device, program-controlled crane automatic hanging device, chain precision braking during crane travel device.

[0026] The described automatic opening and closing device for the well-type furnace cover includes a lifting shaft 12 mounted on the well-type furnace body 1, a furnace arm 3 mounted on the lifting shaft, and a well-type furnace cover 2 fixed under the furnace arm. , gear box 8, lifting spline shaft 11, driving sprocket 10, driving chain 9 and cover block 4 (see figure 1 , figure 2 ). The gear box 8 is driven by the motor 7 and installed on the pit furnace cover 2, the lifting spline shaft 11 is fixed on the top of the lifting shaft 12, and the center of the driving sprocket 10 is milled into a spline corresponding to the lifting spline shaft 11 Type in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com