Abrasion-resistance sensor applied to mining industry

A sensor and anti-wear technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of short service life, low detection accuracy, inconvenient installation and disassembly, etc., to improve service life, improve strength and wear resistance, and maintain test results accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

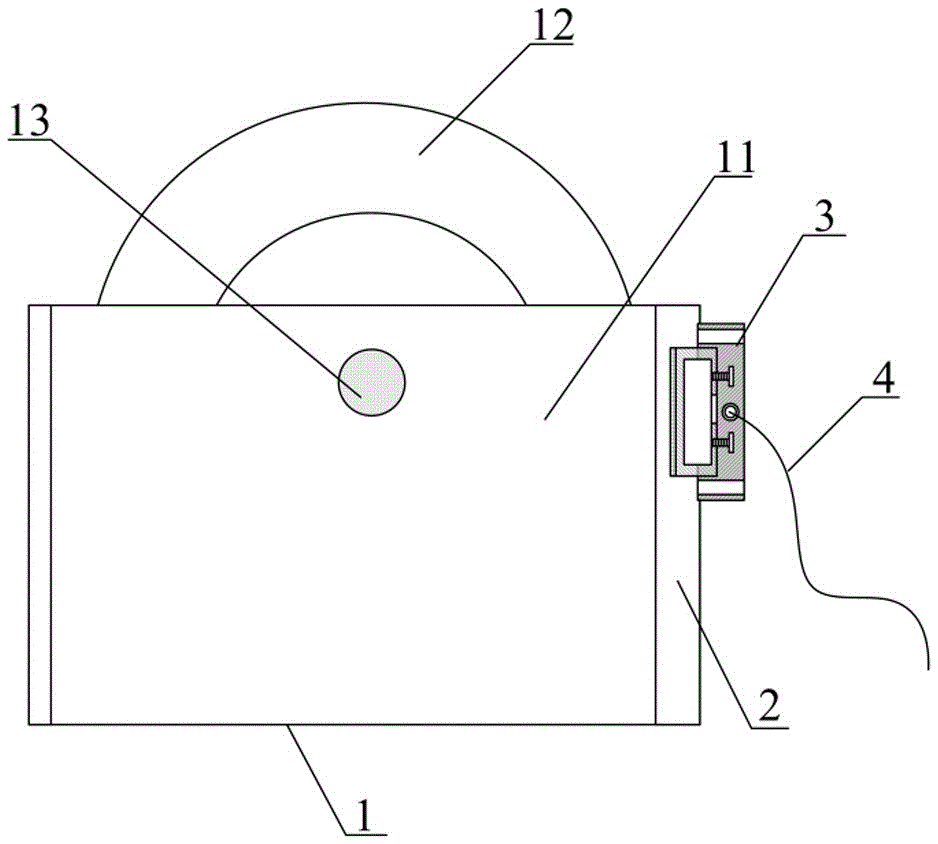

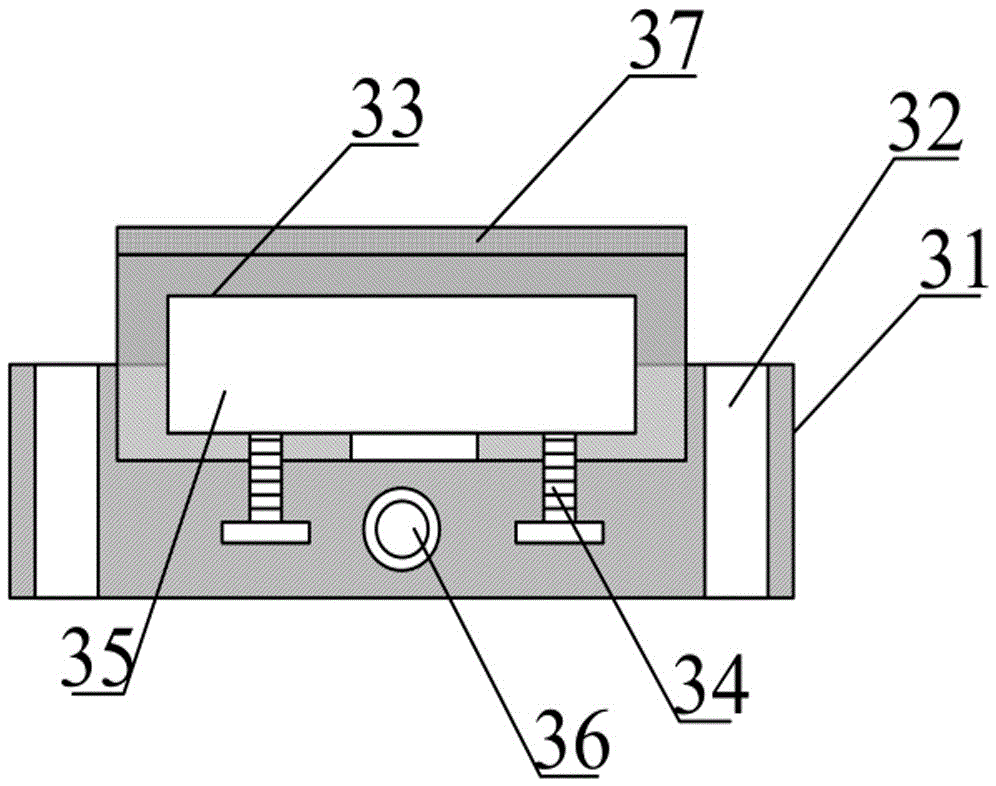

[0022] as attached figure 1 And attached figure 2 shown

[0023] The present invention provides a wear-resistant sensor in the mining industry, comprising a roller knife device 1, a mounting frame 2, a detection device 3 and an external cable 4, and the detection device 3 is connected to the roller knife device 1 through the mounting frame 2; The external cable 4 is electrically connected to the detection device 3; the roller cutter device 1 includes a shell 11, a roller cutter body 12 and an installation shaft 13, and the roller cutter body 12 is installed in the housing 11 by the installation shaft 13; The detection device 3 comprises a pedestal 31, a mounting hole 32, a protective shell 33, a fixing bolt 34, a sensor 35, a cable interface 36 and a superhard alloy plate 37, and the described mounting hole 32 is arranged on the pedestal 31; the protective shell 33 is installed in the pedestal 31 through fixing bolts 34; the sensor 35 is installed inside the protective shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com