Data table-based product tracing method and system

A data sheet and product technology, applied in the field of product traceability method and system based on data sheet, can solve the problems of production line production efficiency reduction, inability to trace product production, lack of products, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

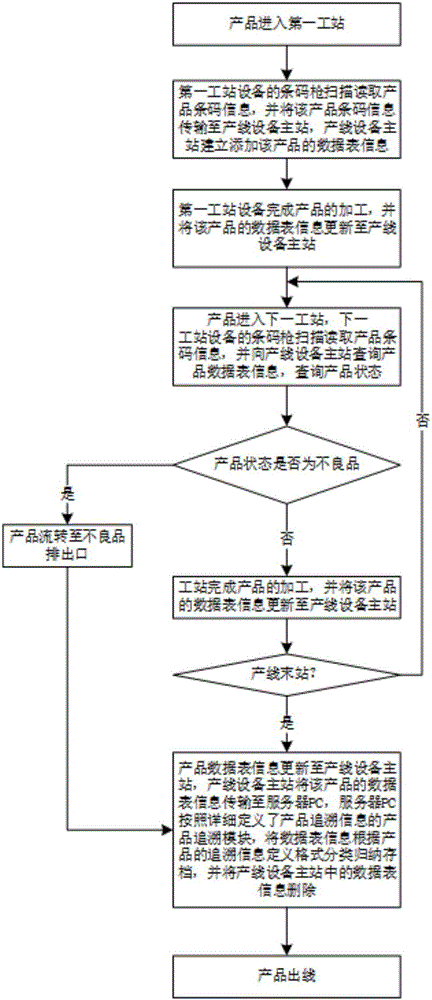

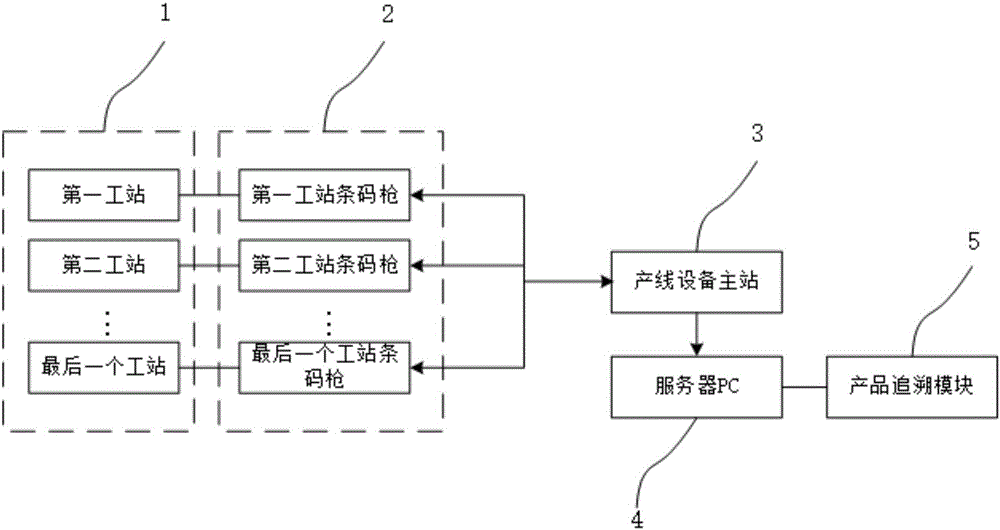

[0022] Such as Figure 1-2 As shown, a kind of data sheet-based product traceability method of the present embodiment includes the following steps:

[0023] S1: When the product enters the first station, the barcode gun of the first station equipment scans and reads the product barcode information, and transmits the product barcode information to the main station of the production line equipment, and the main station of the production line equipment establishes and adds the data of the product Table information, data table information includes product barcode, tool barcode, product station, product status, product inbound time, product outbound time, product defect occurrence station, defect code, defect cause description, key product process Parameter type, product key process parameter value and product key process parameter good or bad results, etc.;

[0024] S2: The equipment at the first station completes the processing of the product, and updates the data sheet informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com