Corrosion equipment for copper clad plate

A copper-clad plate and equipment technology, which is applied in the field of copper-clad plate corrosion equipment, can solve the problems of mixing, environmental pollution, etc., and achieve the effect of reducing the number of times and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

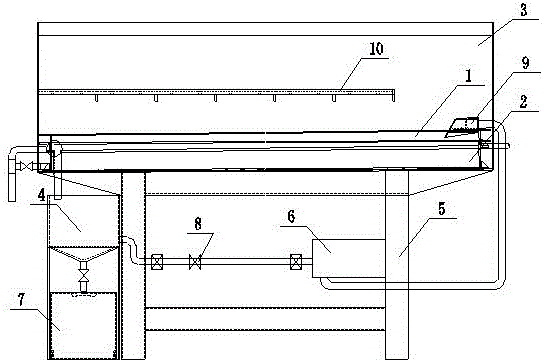

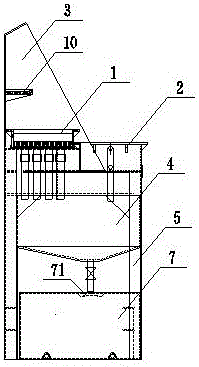

[0014] like figure 1 and figure 2 As shown, a copper-clad plate corrosion equipment includes a bracket 5, a corrosion tank 1, a liquid storage tank 4 and a magnetic centrifugal pump 6, the corrosion tank 1 is slightly inclined, and the liquid storage tank 4 is located below the water outlet at the lower end of the corrosion tank 1. The liquid storage tank 4 is connected to the water inlet of the magnetic centrifugal pump 6 through a pipeline and a switch 8. The top of the bracket 5 is in the shape of a step, the front is low and the back is high. The corrosion tank 1 is fixed on the upper step, and the water tank 2 is fixed on the lower step. The length of the water tank 2 is approximately equal to that of the corrosion tank 1, and the high end of the corrosion tank 1 is provided with a bulk liquid box 9, which is connected to the water outlet of the magnetic centrifugal pump 6 through a pipeline; the water inlet of the magnetic centrifugal pump 6 is arranged horizontally , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com