A device for removing waste fabric accessories

A technology for accessories and fabrics, applied in the field of waste fabric accessories removal devices, can solve the problems of reduced production efficiency, inconvenient removal, non-system, etc., and achieve the effect of reducing frictional force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

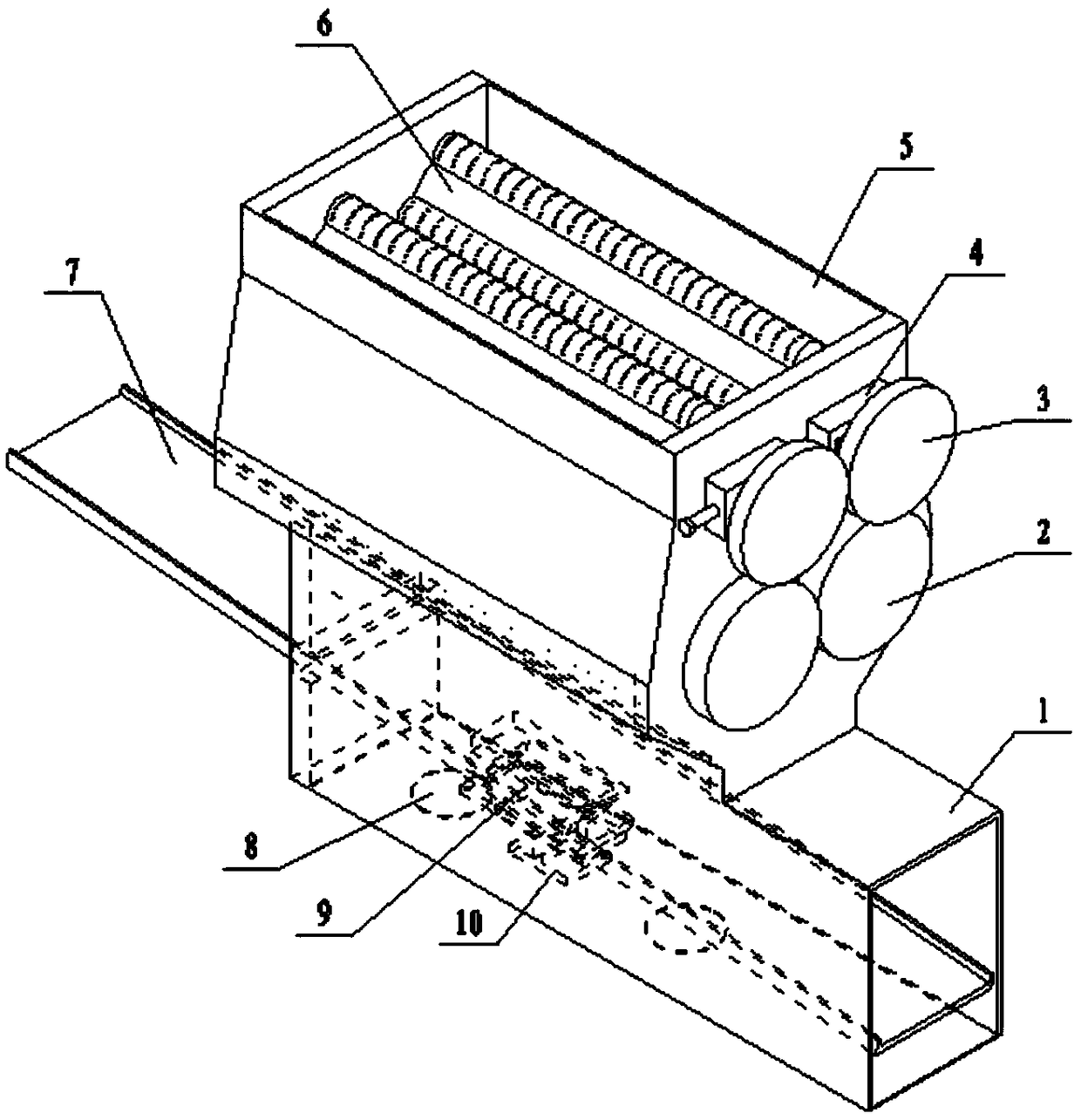

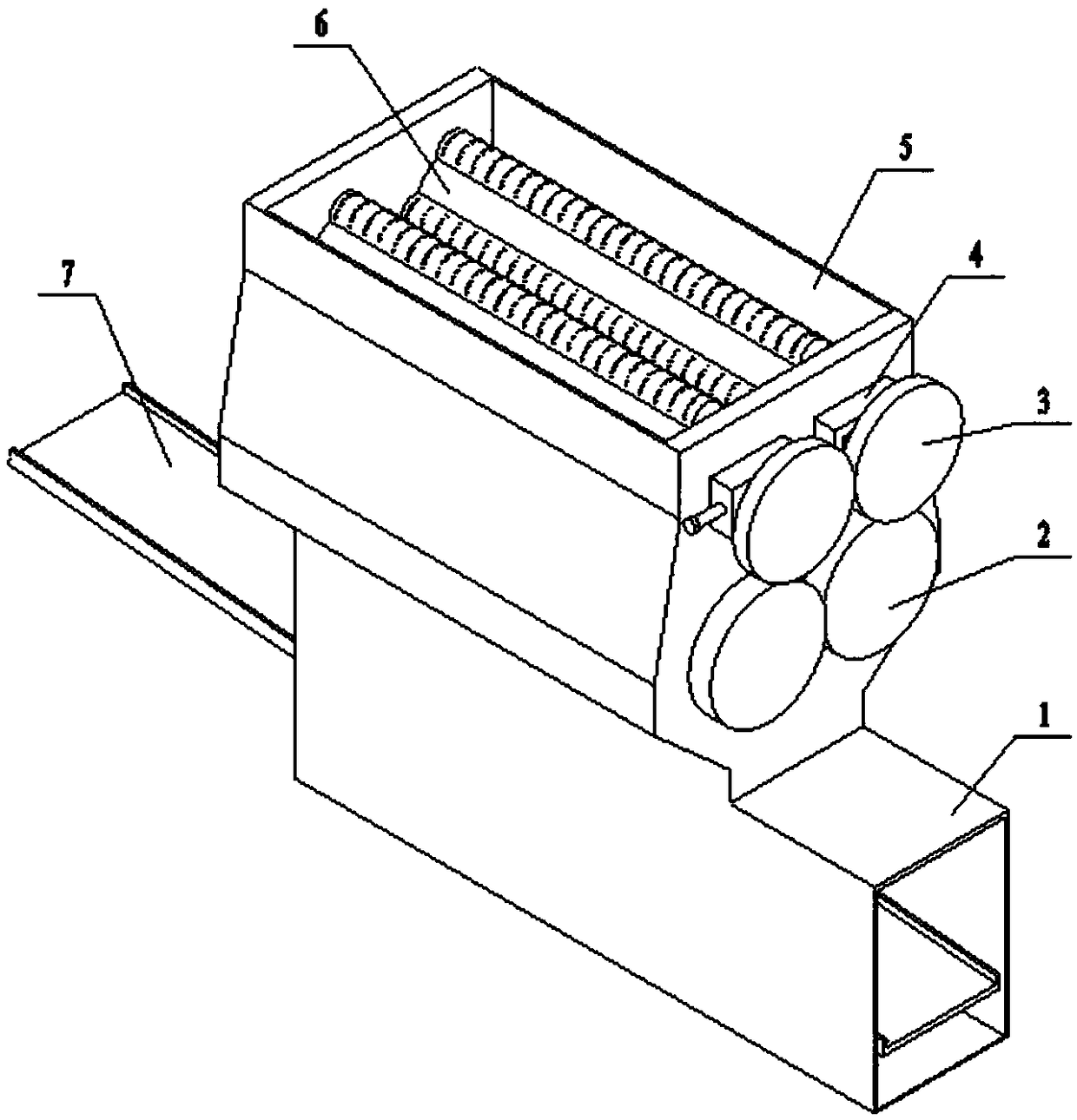

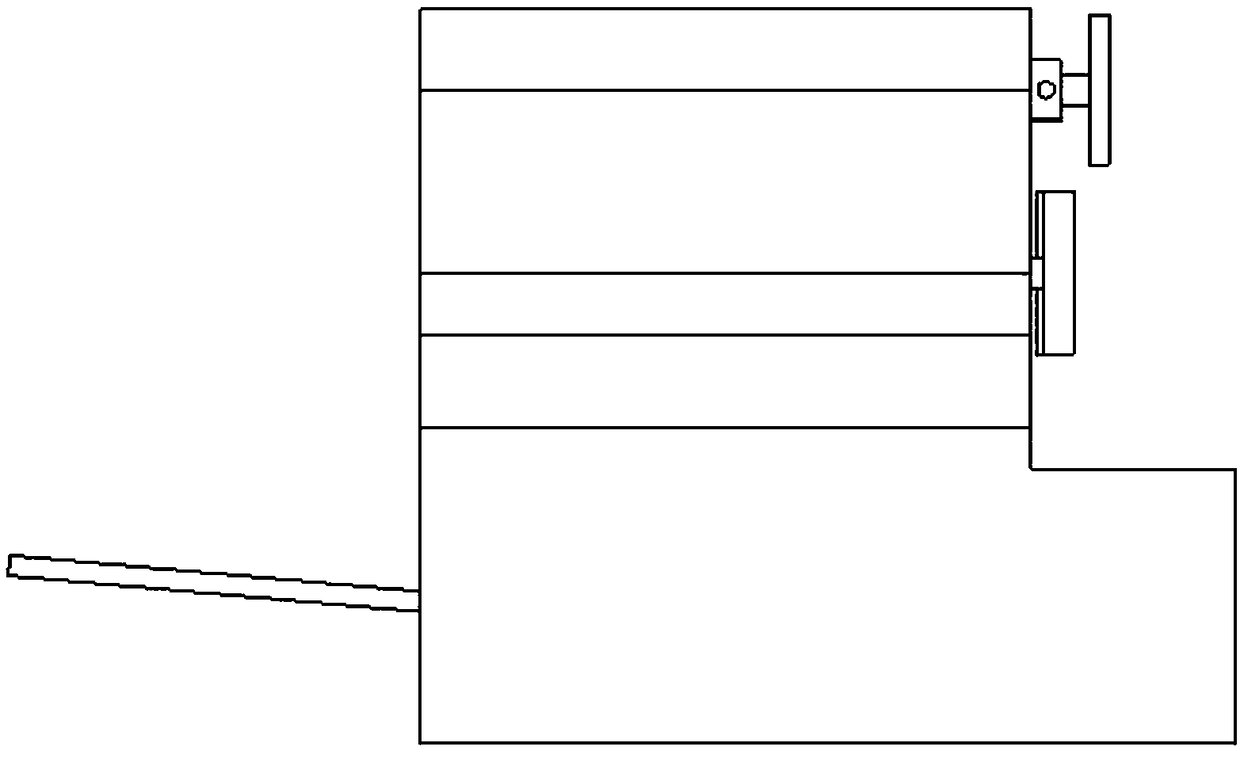

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described with reference to the accompanying drawings.

[0035] Such as Figure 1-Figure 7 As shown, a waste fabric accessory removal device includes a feed bin 5 and two hobs 12, the feed bin 5 is used to put waste clothes, the hob 12 is used to shred clothes, two The hobs 12 are installed side by side in the feed bin 5, and the two hobs 12 are interleaved with each other. One end of the two hobs 12 extends out of the feed bin 5 and is respectively connected with gears, and the two gears mesh And it is connected with a reduction motor to drive the gear to rotate, the two hobs 12 rotate towards each other, and the clothes enter between the hobs 12 and are chopped by the hobs 12;

[0036] The feed bin 5 is also provided with two parallel squeezing rollers 6, the squeezing rollers 6 are arranged above the hob 12 to clamp the clothes, and the hob 12 at the bottom is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com