Flexible production line

A flexible production line and workpiece technology, which is applied in sorting and other directions, can solve the problems of single function, time-consuming and labor-intensive, and low precision of flexible production lines, and achieve the effect of improving workpiece detection efficiency, accuracy, and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

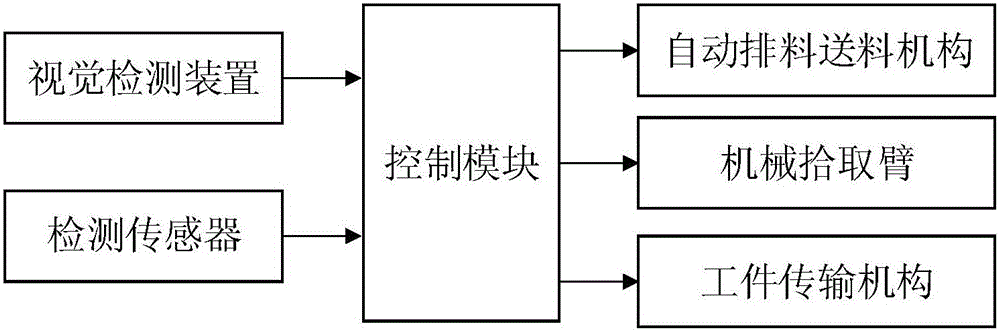

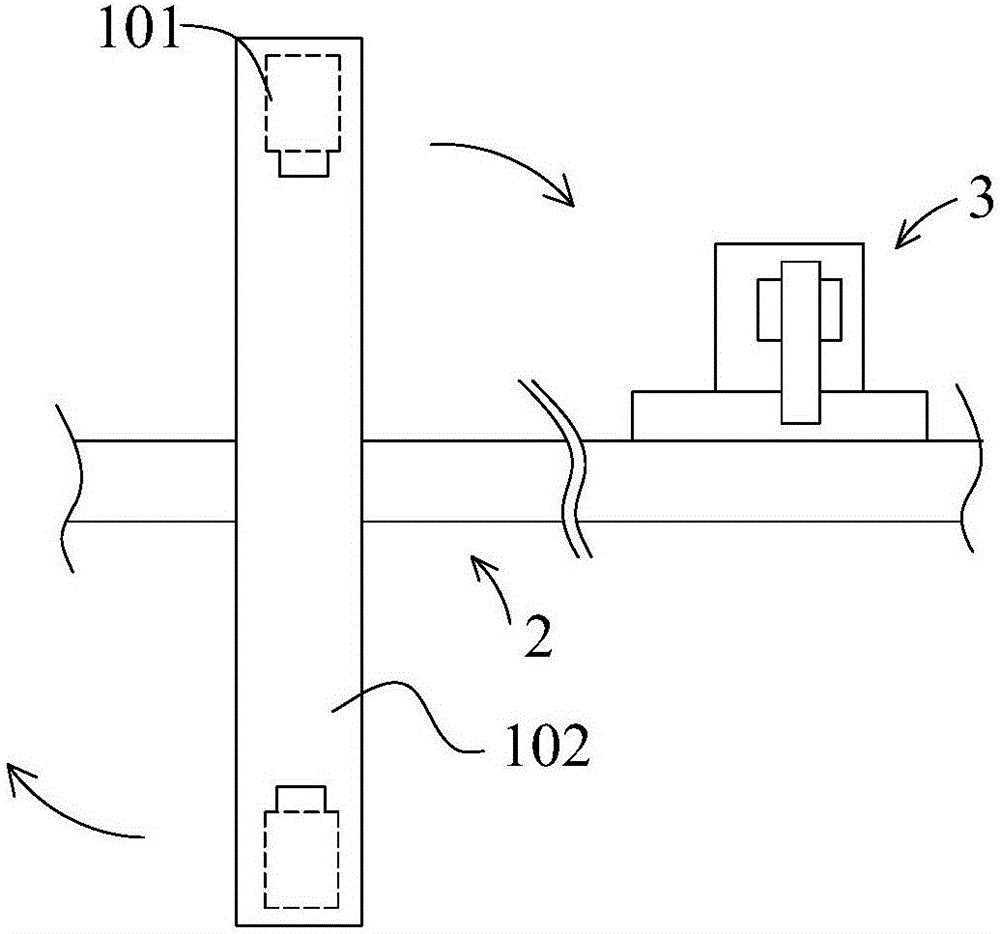

[0026] Such as figure 1 and figure 2 As shown, a flexible production line of the present invention includes: a control module, an automatic discharge and feeding mechanism connected to the control module, a visual inspection device, a mechanical pick-up arm and a workpiece transmission mechanism for transmitting the workpiece to be measured; the automatic The discharge and feeding mechanism transports the workpiece to be tested to the workpiece transmission mechanism; the visual detection device is set up on the workpiece transmission mechanism, and detects the workpiece to be tested; when it is recognized that the workpiece to be tested has a defect, the control module controls the mechanical pick-up The arm picks up the measured workpiece.

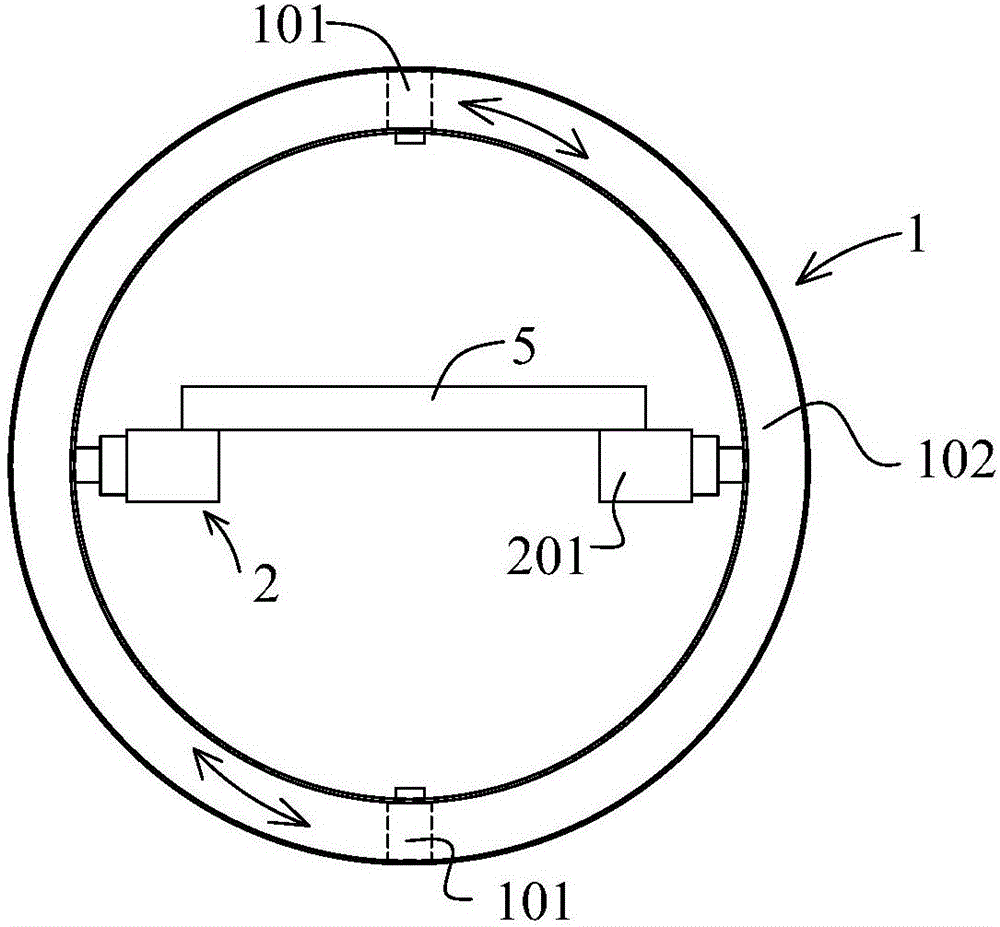

[0027] Among them, the automatic discharge and feeding mechanism includes: a circular vibrating plate and a linear vibrating body. When the workpiece to be measured enters the arrangement of the linear vibrating body through the circul...

Embodiment 2

[0046] Such as Figure 1 to Figure 5 As shown, on the basis of embodiment 1, this embodiment 2 also provides a working method of a flexible production line.

[0047] Wherein the flexible production line includes: a control module, an automatic discharge and feeding mechanism connected to the control module, a visual inspection device, a mechanical pick-up arm and a workpiece transmission mechanism for transferring the workpiece to be measured; the working method includes: the automatic The discharge and feeding mechanism transports the workpiece to be tested to the workpiece transmission mechanism; the visual detection device is set up on the workpiece transmission mechanism, and detects the workpiece to be tested; when it is recognized that the workpiece to be tested has a defect, the control module controls the mechanical pick-up The arm picks up the measured workpiece.

[0048] The visual detection device includes: two cameras, and a circular guide rail sleeved on the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com