A kind of manufacturing method of self-propagating diamond engraving grinding head

A manufacturing method and self-propagating technology, applied in the direction of manufacturing tools, abrasives, grinding devices, etc., can solve the problems of high cost, limited sharpness, and unimproved service life, and achieve low investment and production costs and long service life Long, strong holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

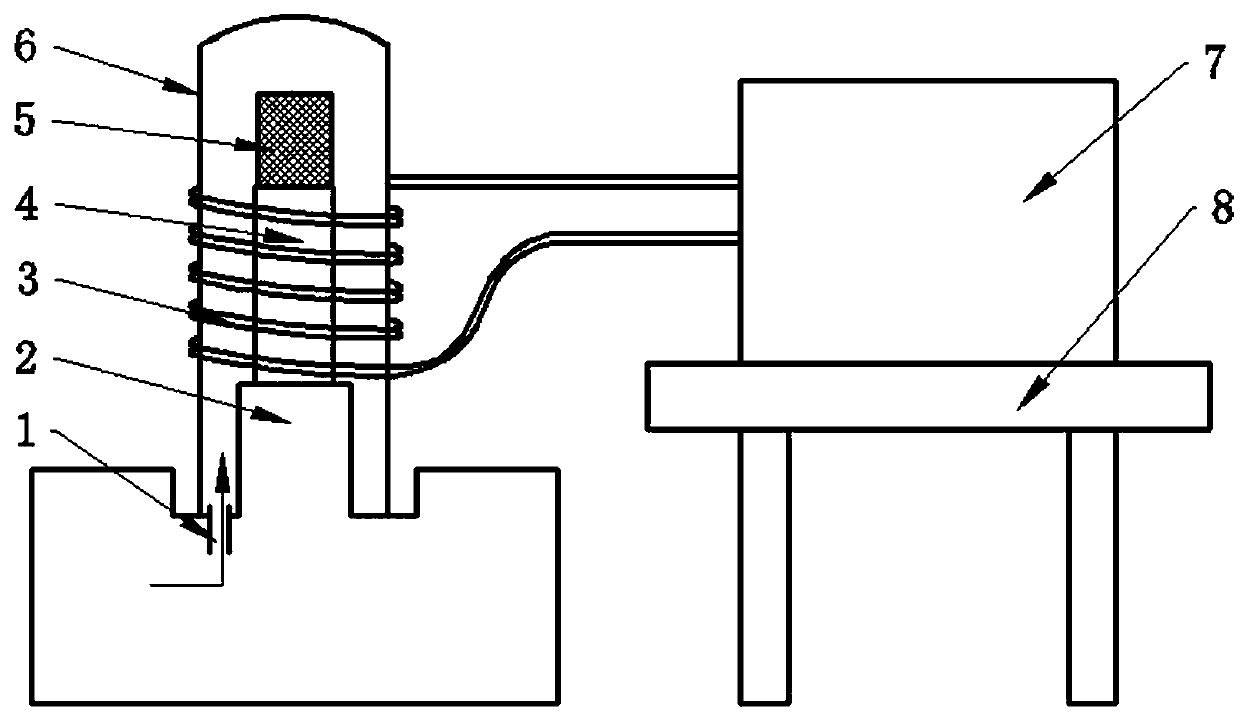

Image

Examples

Embodiment 1

[0030] A self-propagating diamond engraving grinding head. The outer diameter of the engraving grinding head is 4mm. The components of the working layer include bonding agent and abrasive. The bonding agent includes Ti, Al, Ni, Cu, Sn powder, and the weight of Ti powder is 45 parts. The weight of Al powder is 25 parts, the weight of Ni powder is 10 parts, the weight of Cu powder is 15 parts, the weight of Sn powder is 2 parts, the abrasive is diamond, the concentration is 130%, the particle size is 230 / 270 mesh.

[0031] A manufacturing method of a self-propagating diamond engraving grinding head includes the following steps:

[0032] 1) Put Ti, Al, Ni, Cu, Sn in the above mass parts into a ball mill and mix well, then add diamond and mix well to obtain working layer powder, wherein the speed of the ball mill is 100r / min, The ball milling time is 4 hours, the ball-to-battery ratio is 1:5, and the total volume of the steel ball and powder does not exceed 50% of the ball milling ta...

Embodiment 2

[0036] A self-propagating diamond engraving grinding head. The outer diameter of the engraving grinding head is 6mm. The components of the working layer include bonding agent and abrasive. The bonding agent includes Ti, Al, Ni, Cu, Sn, Co powders, and the weight parts of Ti powder 35 parts by weight, 20 parts by weight of Al powder, 8 parts by weight of Ni powder, 25 parts by weight of Cu powder, 3 parts by weight of Sn powder, 2 parts by weight of Co powder, abrasive It is diamond with a concentration of 115% and a particle size of 120 / 140 mesh.

[0037] A manufacturing method of a self-propagating diamond engraving grinding head includes the following steps:

[0038] 1) Put the Ti, Al, Ni, Cu, Sn, Co powders in the above mass parts into a ball mill and mix well, then add diamond and mix well to obtain working layer powder, wherein the ball mill rotates at 125r / min, the milling time is 4.5h, the ball-to-battery ratio is 1:6, and the total volume of the steel ball and powder does...

Embodiment 3

[0042] A self-propagating diamond engraving grinding head. The outer diameter of the engraving grinding head is 8mm. The components of the working layer include bonding agent and abrasive. The bonding agent includes Ti, Al, Ni, Cu, Sn, Co powders, and the weight parts of Ti powder 30 parts by weight, 20 parts by weight of Al powder, 6 parts by weight of Ni powder, 35 parts by weight of Cu powder, 4 parts by weight of Sn powder, 5 parts by weight of Co powder, abrasive It is diamond with a concentration of 100% and a particle size of 80 / 100 mesh.

[0043] A manufacturing method of a self-propagating diamond engraving grinding head includes the following steps:

[0044] 1) Put the Ti, Al, Ni, Cu, Sn, Co powders in the above mass parts into a ball mill and mix them evenly, then add diamond and mix well to obtain working layer powder, wherein the ball mill rotates at 150r / min, the ball milling time is 5h, the ball-to-battery ratio is 1:8, and the total volume of the steel ball and po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap