Novel anticollision injection mold

An injection mold and anti-collision technology, which is applied in the field of new anti-collision injection molds, can solve problems such as time-consuming and laborious, difficult to reset the ejector pin, and lack of counting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

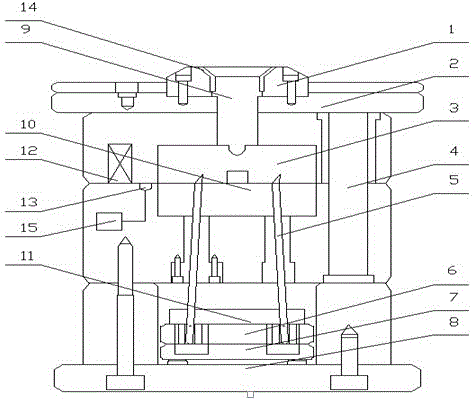

Embodiment 1

[0009] A new type of anti-collision injection mold, including: positioning ring 1, upper fixing plate 2, die 3, guide post 4, ejector rod 5, upper ejector plate 6, lower ejector plate 7, lower fixing plate 8, sprue 9. Punch 10, limit controller 11, limit block 12, photoelectric switch 13, detachable sprue sleeve 14, counter 15, positioning ring 1 is installed on the upper fixing plate 2, and detachable gate is installed on the positioning ring 1 Set 14, the sprue 9 is opened under the detachable sprue sleeve 14, the die 3 is installed under the upper fixed plate 2, the guide post 4 is installed on one side of the die 3, the limit block 12 is installed on the side of the die 3, and the limit block 12 The photoelectric switch 13 is installed below, the counter 15 is connected under the photoelectric switch 13, the punch 10 is installed under the die 3, the ejector rod 5 is installed under the punch 10, the upper ejector plate 6 is installed under the punch 10, and the upper eject...

Embodiment 2

[0011] The injection molding machine injects the raw material into the runner 9 through the detachable sprue sleeve 14, the raw material flows into the space between the concave mold 3 and the convex mold 10 to cool and form, the upper and lower molds are opened, and the ejector rod 5 ejects the workpiece, and the photoelectric The switch 13 loses the barrier and triggers the counter 15, and the counter 15 adds one to the value. If the ejector rod 5 is pushed out of the workpiece, if it is not reset, the limit controller 11 will control the limit block 12 to stand between the upper and lower molds, so that the mold cannot be moved again. Clamp the mold to prevent the mold from being damaged when the ejector pin 5 is not reset and closes the mold again. If the sprue sleeve has residual raw materials, the staff can separately disassemble the detachable sprue sleeve 14 for cleaning without removing the positioning ring 1 entirely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com