Full-automatic double-color screen printing machine and automatic screen printing method

A fully automatic, screen printing machine technology, used in screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of low production efficiency, high labor intensity, poor two-color printing quality, etc., to improve production efficiency and reduce operations. Steps, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

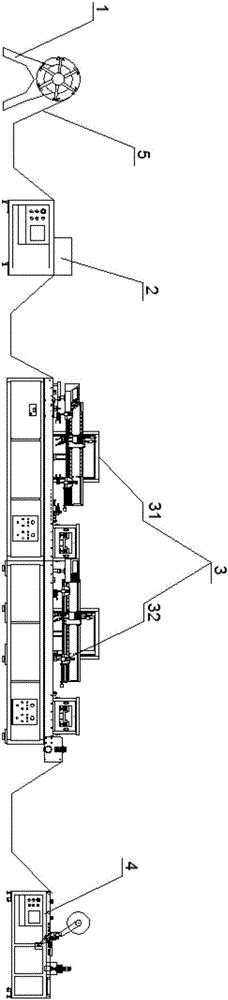

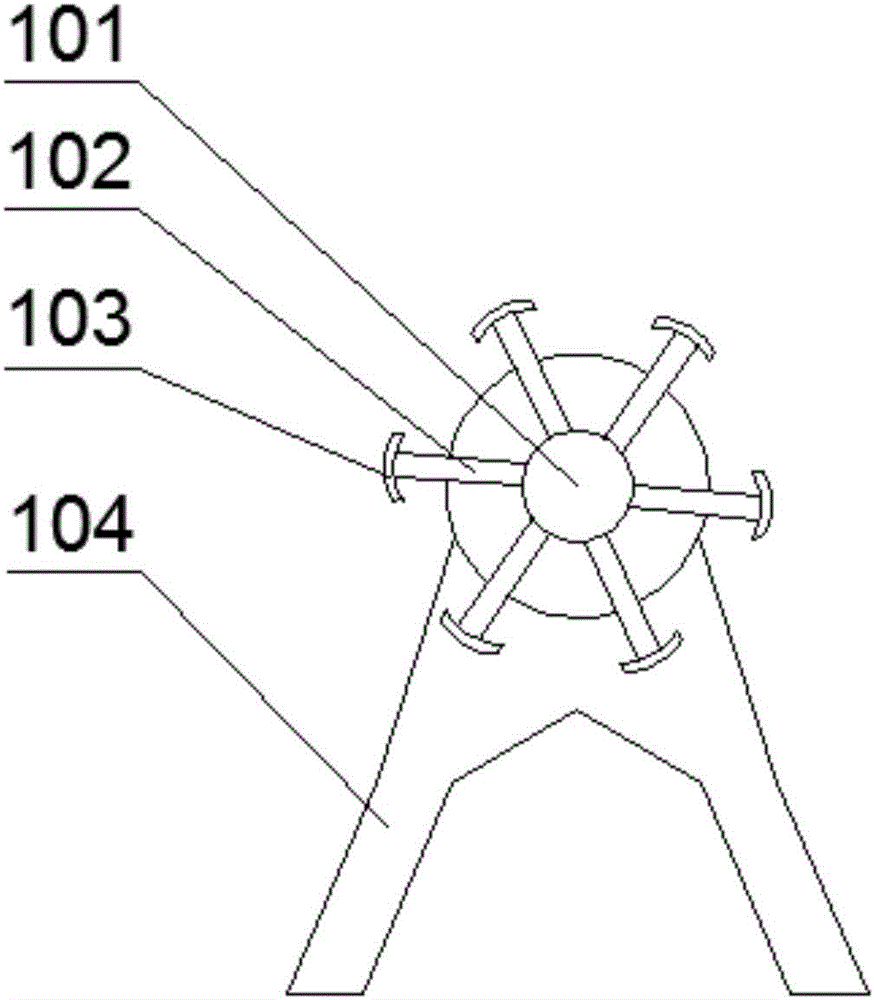

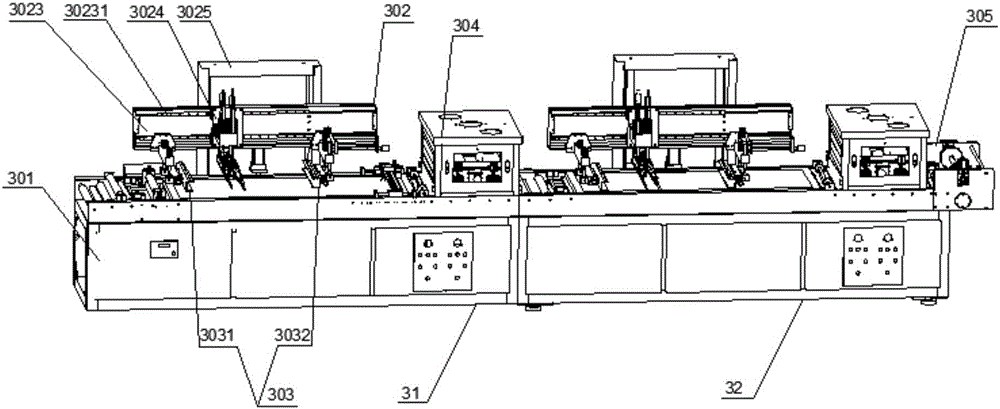

[0033] Automatic two-color screen printing machine, such as Figure 1-10As shown, it includes a feeding device 1, a leveling device 2, a printing host 3 and a film cutting device 4, the feeding device 1 is connected to the leveling device 2, the leveling device 2 is connected to the printing host 3, and the printing host 3 is connected to the coating Cutting device 4 is connected, and feeding device 1 comprises support 104, rotating shaft 101, support rod 102 and support pad 103, and support 104 is provided with rotating shaft 101, and supporting rod 102 is distributed in the periphery of rotating shaft 101, and supporting rod 102 is provided with There is a support pad 103 for supporting the rolled aluminum plate 5 . The feeding device 1 transports the coiled aluminum sheet 5 in a rolling manner through the rotating shaft 101 and the support rod 102, compared with the traditional manual feeding one by one, it has the effect of being suitable for automatic mass production and ...

Embodiment 2

[0042] An automatic screen printing method such as Figure 1-4 As shown, the automatic two-color screen printing machine described in Embodiment 1 is adopted, and the automatic screen printing method includes:

[0043] Transport step, transporting the roll-shaped aluminum plate 5 to the vicinity of the feeding device 1;

[0044] In the feeding step, the coiled aluminum plate 5 is put into the feeding device 1, the support pad 103 is pressed against the aluminum plate 5, the rotating shaft 102 is started, and the rotating shaft 102 drives the aluminum plate 5 to rotate and feed;

[0045] In the leveling step, the leveling device 2 levels the aluminum plate 5 and transfers the aluminum plate 5 to the first printing host 31;

[0046] In the first color silk screen printing step, the first printing host 31 prints the first color on the aluminum plate 5 through the silk screen scraping head device 302, and the second printing host 32 prints the second color on the aluminum plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com