Method for segmented forming and product packaging of hard paste cartons

A product packaging and carton technology, applied in packaging and other directions, can solve the problems of large volume of finished packaging boxes, high storage and transportation costs, and a large amount of labor, so as to save storage and transportation costs, save storage and transportation space, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

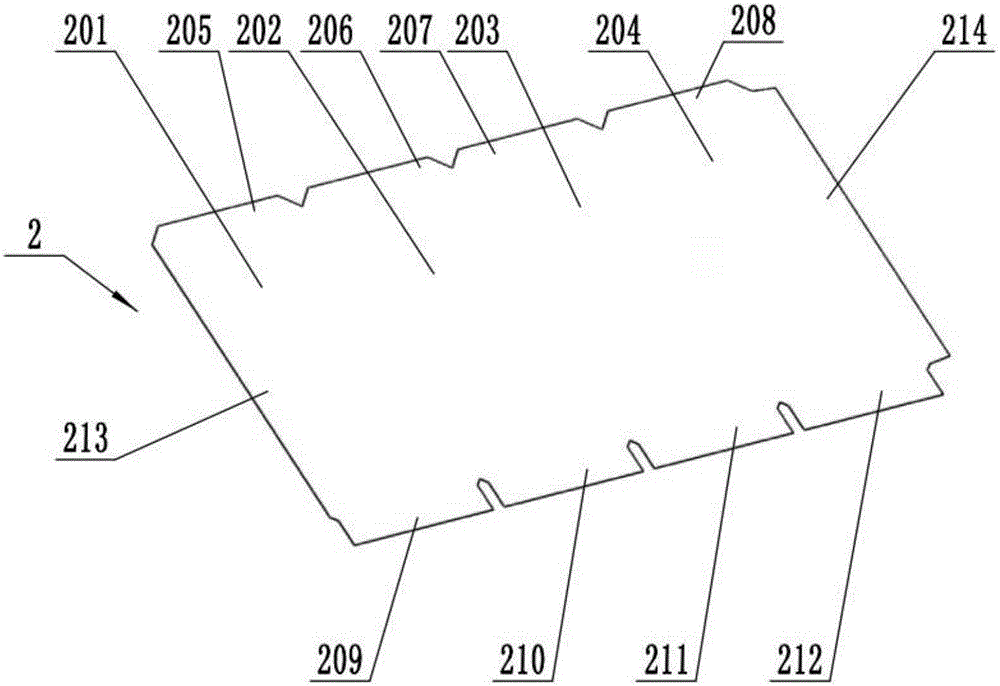

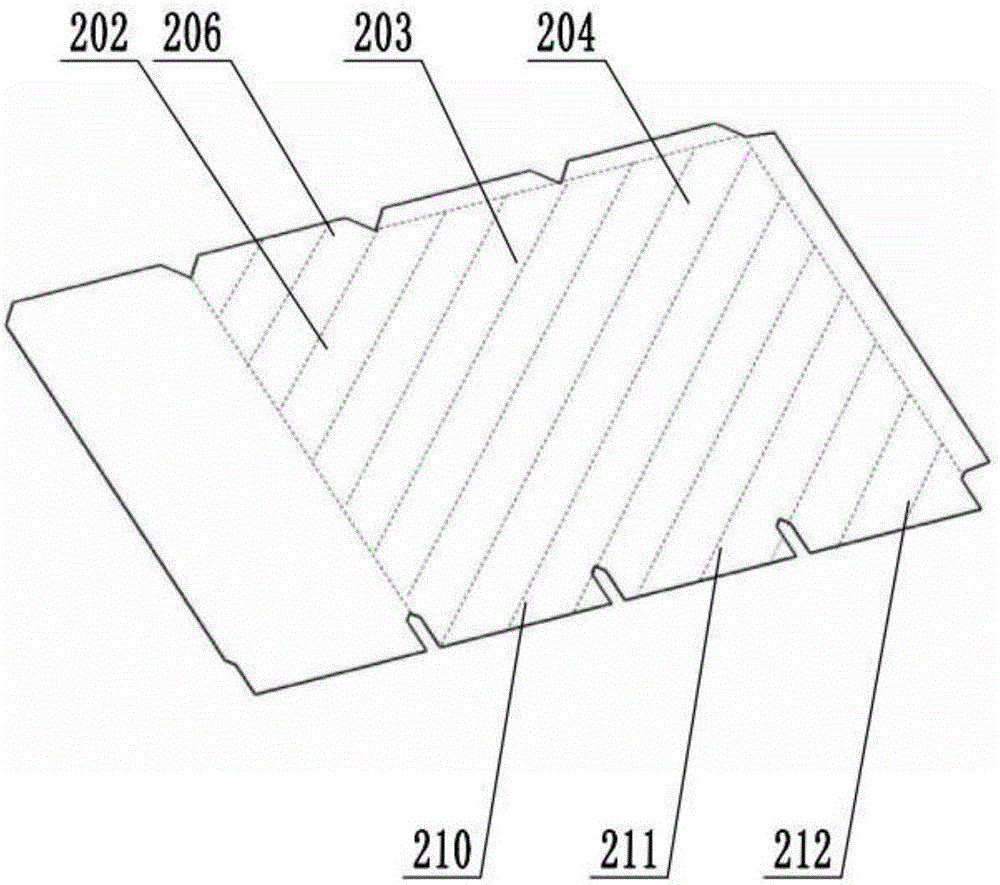

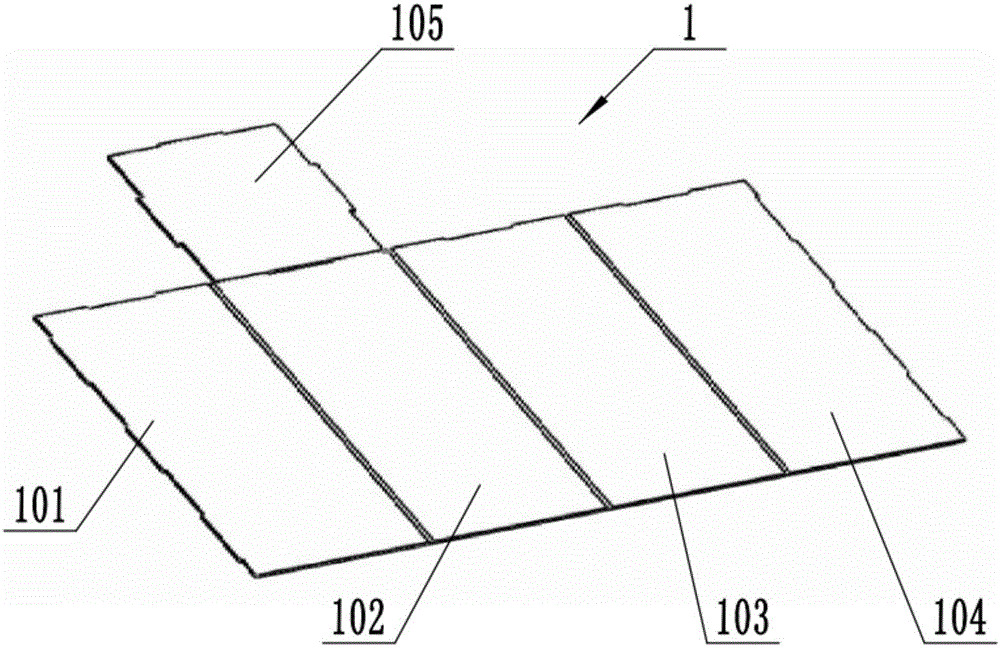

[0042] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0043] Such as figure 1 As shown, the present invention provides a kind of segmental forming and product packaging method of hard pasting paper box, and this method comprises four processes as a whole, is respectively (1) the forming process of flat box blank; (2) flat box blank The storage and transportation process; (3) the process of folding the flat box blank into a cylindrical box; (4) the product packaging process. The process of folding the flat box blank into a cylindrical box body and the product packaging process are completed on the same production line. Among them, the forming process of the flat box blank is completed in the carton packaging manufacturer, and the folding process of the flat box blank into a cylindrical box and the product packaging process are completed in the wine enterprise packaging factory. It can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com