Lapel-type bag shaper with multiple conical surfaces

A bag forming and multi-cone technology, which is applied in the direction of containers, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of increasing the overall height of the bag forming machine, composite material bag making, and reducing bag making efficiency.

Inactive Publication Date: 2011-01-05

JIANGNAN UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

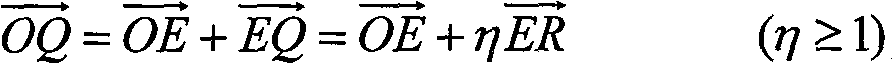

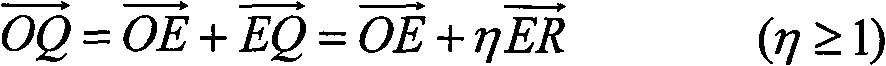

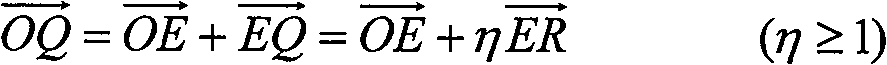

The shoulder curved surface 3' of the existing lapel bag-making former is made of a single conical surface, and the bag-making material forms a longitudinal seam 4' after passing through the lapel bag-making former, and the longitudinal seam is formed by the inner layer and the outer layer of the bag-making material. The layers are overlapped (as shown in Figure 2A). Since the inner layer and the outer layer of the bag-making material are heat-sealed during the bag-making process, only the same bag-making material as the inner layer and the outer layer material can be used, so that the bag-making The selection of materials is limited, and it is not possible to use composite materials with different materials for the inner layer and outer layer to make bags; if the bag-making material needs to form a longitudinal seam where the inner layer is connected to the inner layer (as shown in Figure 2B), an additional transition section is required , after the bag-making material is folded through the transition section, the inner layer is connected to the inner layer. This structure makes the structure of the bag-making machine more complicated, increases the overall height of the bag-making machine, and reduces the bag-making efficiency , but also correspondingly increase the manufacturing cost of the bag forming machine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a lapel-type bag shaper with multiple conical surfaces, which is used for a bag shaping machine. The lapel-type bag shaper comprises a flat back surface, a cylindrical vertical pipe and curved shoulder surfaces and is characterized in that the curved shoulder surfaces consist of first conical curved surfaces and second conical curved surfaces and are tangential at a shared bus, and the two second conical curved surfaces form opposite vertical lapels. Each of the symmetrically-arranged curved shoulder surfaces consists of two curved surfaces which can form the oppositevertical lapels. The bag shaping material passes by the lapel-type bag shaper and forms the vertical line whose inner layers are spliced so that the bag shaping material can not be restricted any more; the bag can be shaped with composite inner layer material and composite outer layer material which are different; the structures of two curved surfaces of each of the symmetrically-arranged curved shoulder surfaces can lower the overall height of the lapel-type bag shaper so as to turn over and shape the piece of flat bag shaping material; in addition, a transition section can be omitted so that the overall height of the bag shaper is lowered, the manufacturing cost is reduced and the bag shaping efficiency is improved.

Description

Multi-cone lapel bag forming machine technical field The invention relates to a packaging mechanical device, in particular to a multi-cone lapel bag forming device of a bag forming machine. Background technique The lapel bag forming machine is a key component of the bag forming machine. As shown in Figures 1A, 1B, and 1C, the lapel bag forming machine includes a back plane 1', a standpipe 2' and two symmetrically arranged on the back plane 1'. The shoulder curved surface 3' on the side, during the bag making process, the flat bag-making material passes through the back plane 1' of the lapel bag forming device and is folded along the shoulder curved surface 3', and then descends along the inner wall of the standpipe 2' to form a cylindrical shape Therefore, when the bag-making material runs on the surface of the lapel bag-making machine, neither the longitudinal nor the transverse direction can be elongated or shortened. The shoulder curved surface 3' of the existing lapel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B31B1/26

Inventor 周一届

Owner JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com