A large flow box material conveying device

A conveying device and high-flow technology, which is applied in the field of large-flow boxed material conveying devices, can solve the problems of damage and scrapping of the boxed material conveying device, and achieve the effect of increasing the diversion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

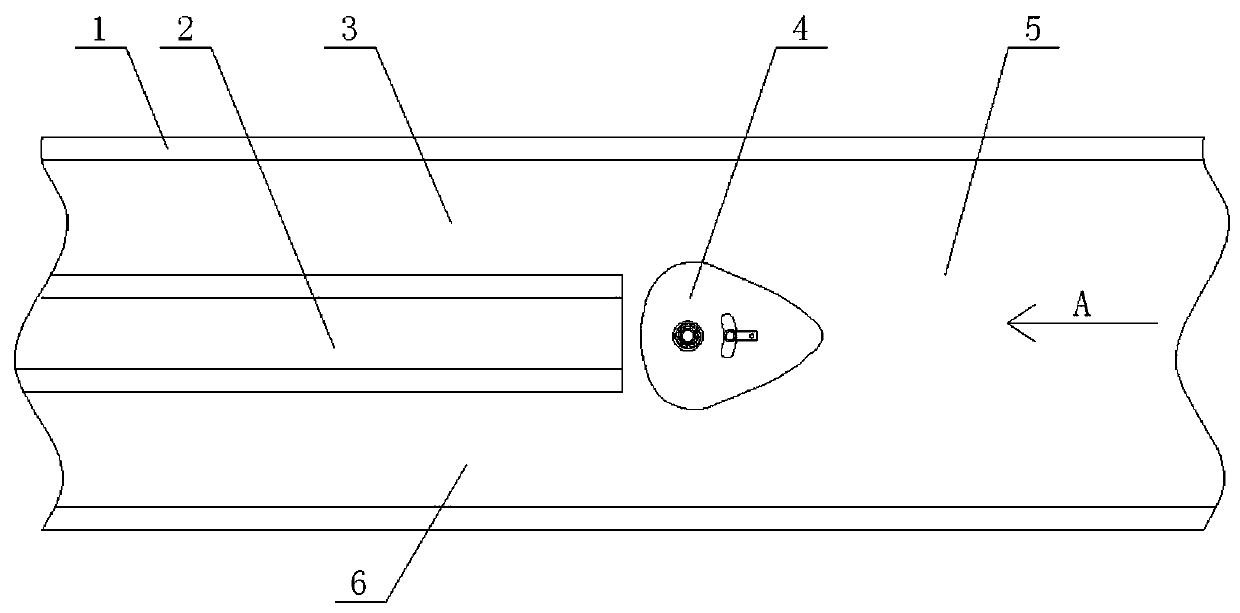

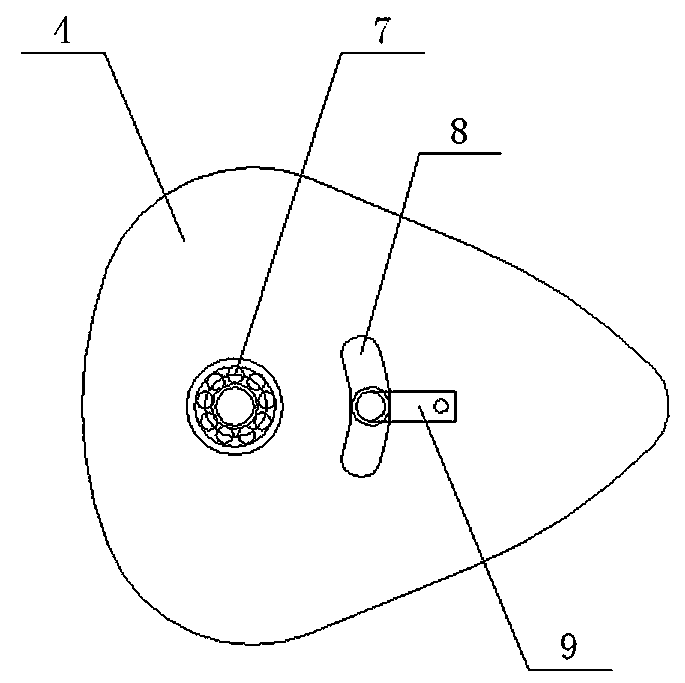

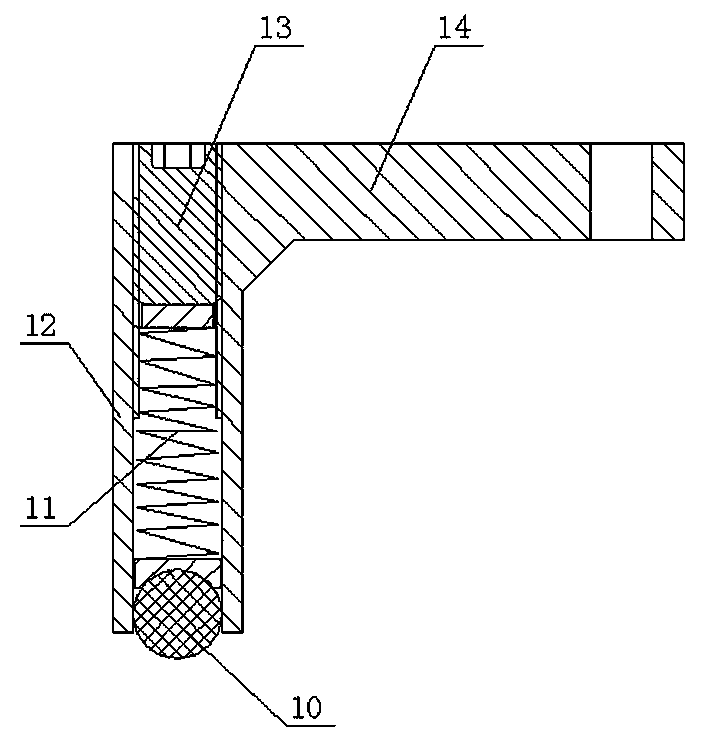

[0016] Such as figure 1 As shown, the present invention includes a transmission frame (not shown in the figure), on which a transmission belt 5 is installed, and the movement direction of the transmission belt 5 is the front direction A, parallel to the transmission belt 5 and in line with the front The vertical direction of direction A is the width direction, and baffle plates 1 are installed along the front and rear directions on the conveyor frame on both sides of the conveyor belt 5, and a support frame (not shown) is installed on the conveyor frame, and the support frame Located above the conveyor frame, a rotating shaft arranged vertically downward is provided on the supporting frame, and a diverter block 4 is rotatably connected to the end of the rotating shaft, and the diverter block 4 is located in the middle of the width direction of the conveyor belt.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com