Patents

Literature

43results about How to "Realize automatic shunt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

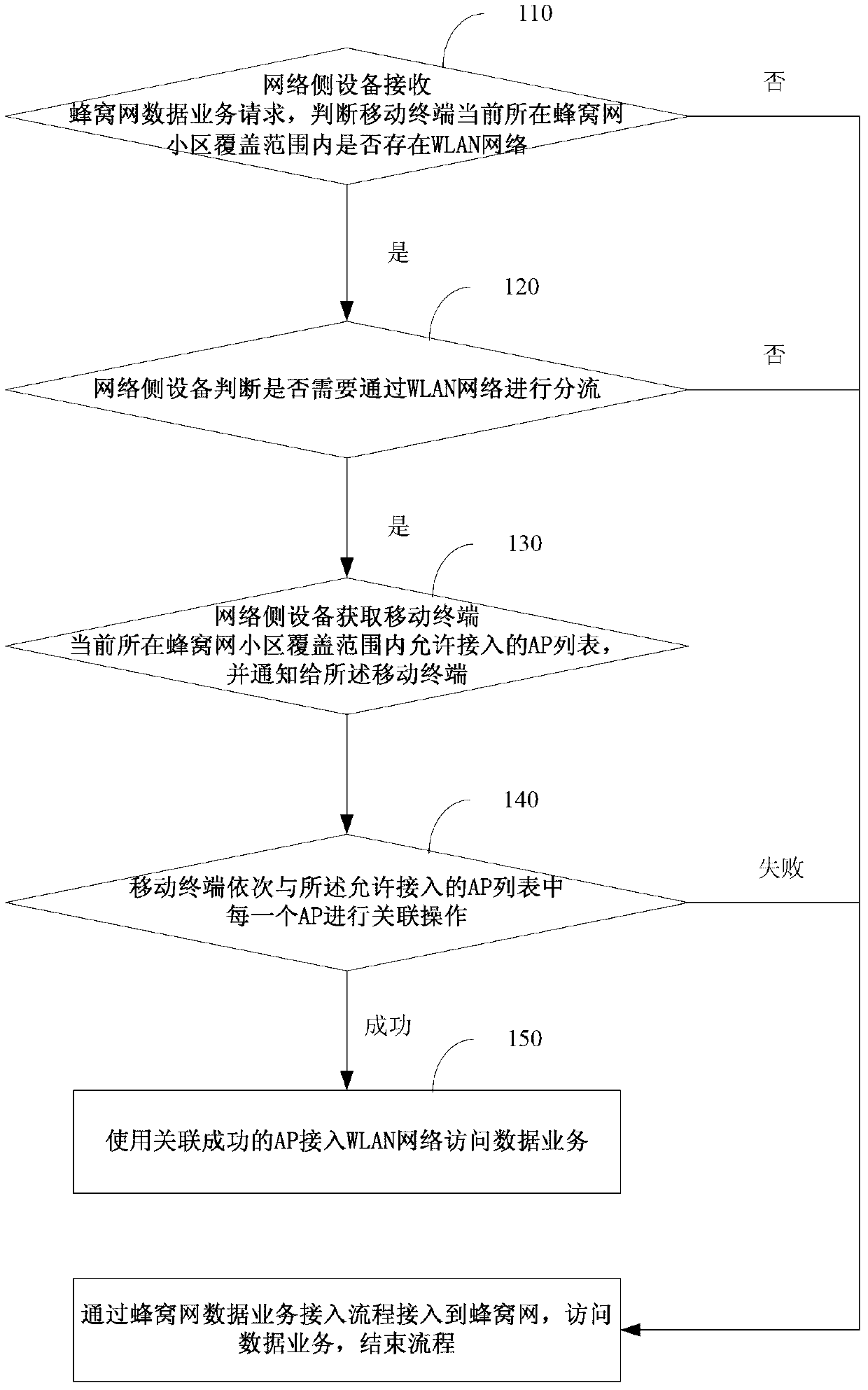

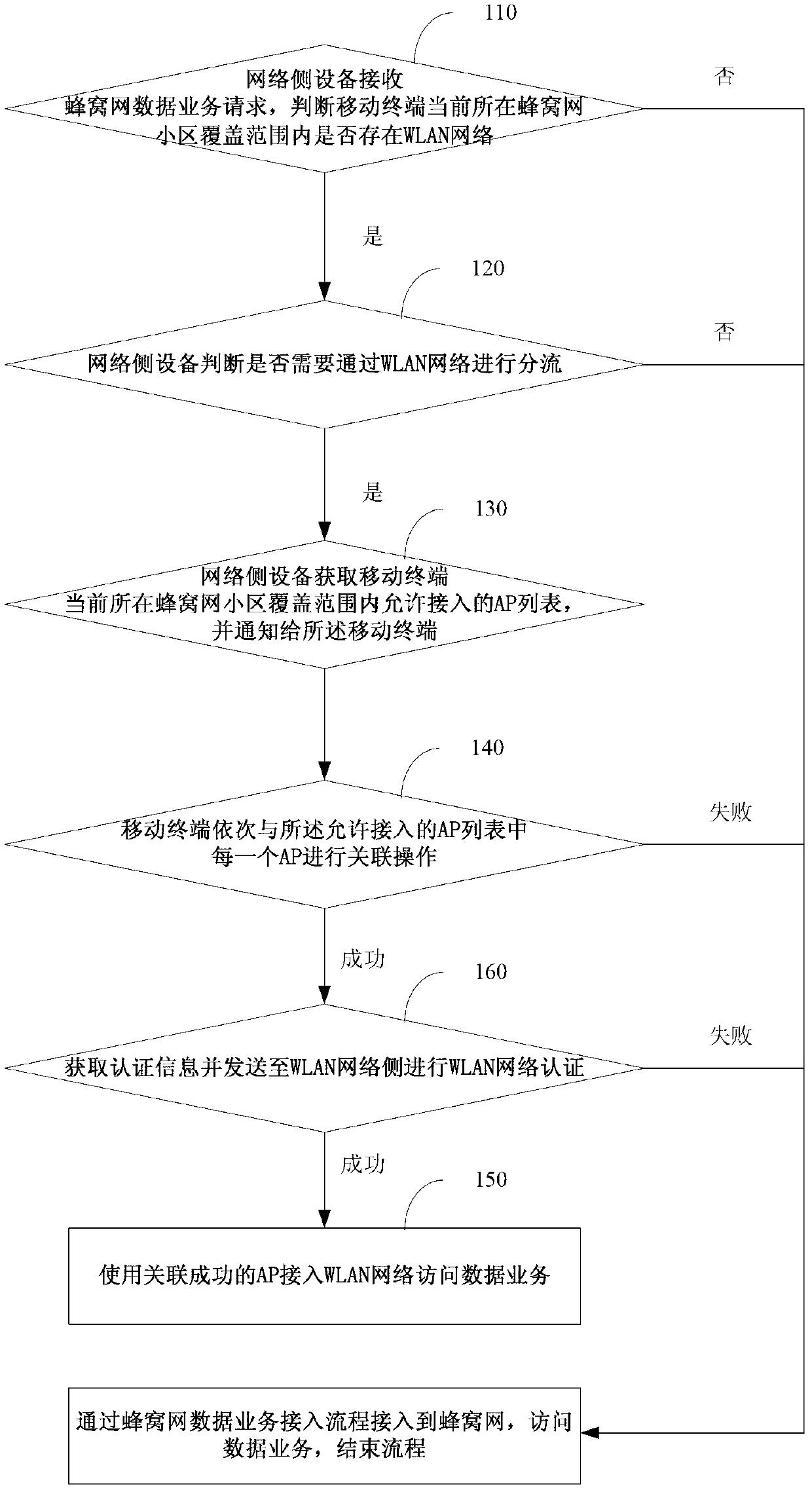

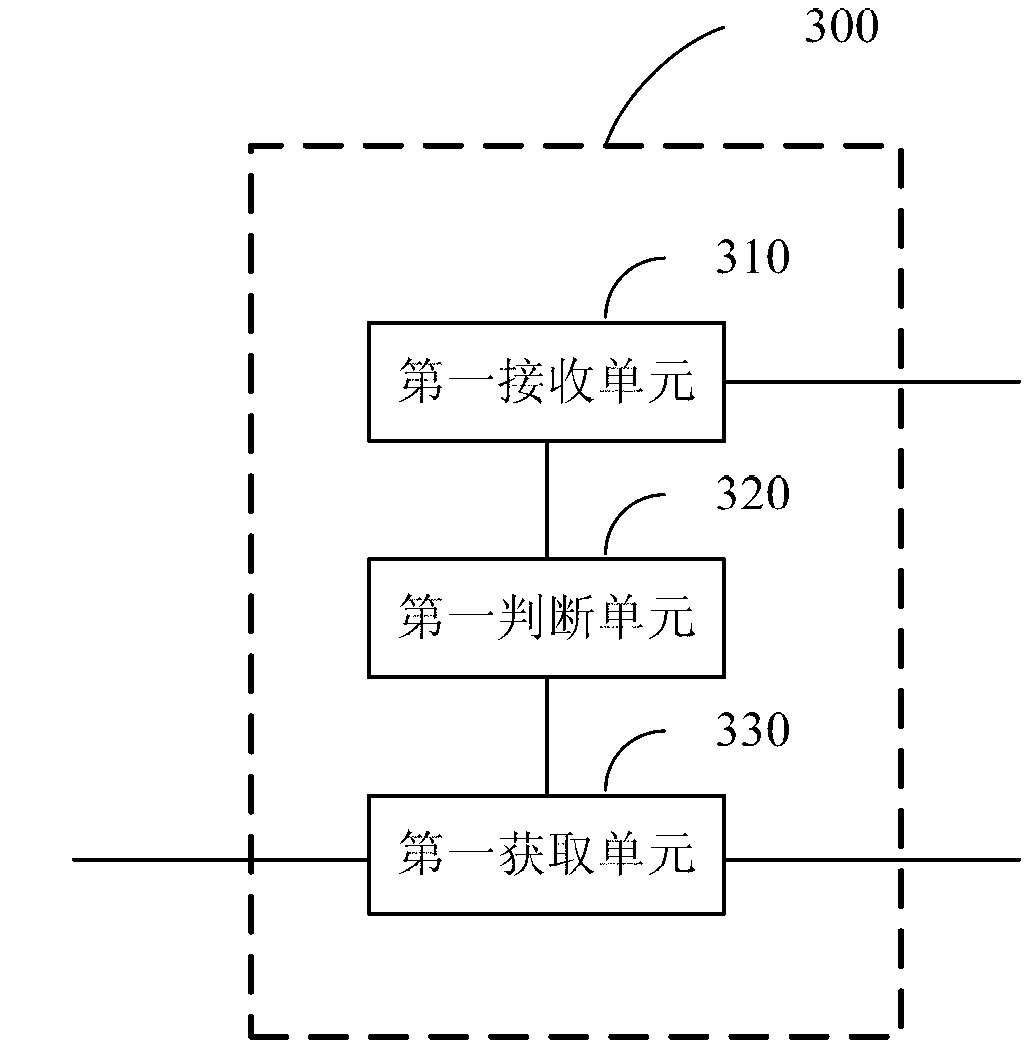

Method, device and system for realizing wireless network access

InactiveCN102740366AIncrease profitRealize automatic shuntNetwork traffic/resource managementAssess restrictionComputer terminalComputer science

The embodiment of the invention discloses a method, device and system for realizing wireless network access. The method comprises the steps of: receiving a cellular network data service request initiated by a mobile terminal, judging whether a wireless local area network (WLAN) exists in a coverage range of a cellular network cell in which the mobile terminal is arranged, if so, judging whether distribution is carried out through the WLAN, if the distribution is carried out through the WLAN, obtaining a list of wireless local area network access points (AP) allowed to be accessed in the coverage range of the cellular network cell where the mobile terminal is, informing the mobile terminal of the list of the APs allowed to be accessed. By adopting the method, the device and the system provided by the embodiment of the invention, data services in a hot spot area can be distributed, and further utilization rate of the WLAN is increased, and service and signaling loads of a cellular network are reduced.

Owner:HUAWEI TECH CO LTD

Method for intelligently adjusting online queuing priority of customer service system

InactiveCN107274893AImprove the resolution rateReduce the risk of complaintsSpecial service for subscribersSpeech recognitionChronological timeSpeech sound

The invention discloses a method for intelligently adjusting an online queuing priority of a customer service system, wherein the method relates to the field of communication technology. The method comprises the following steps of S1, acquiring a telephone number of an incoming call client, comparing the telephone number of the client with a VIP client telephone number database, detecting whether the client is a VIP client through telephone number detection, if yes, switching the client to a VIP channel, and otherwise, switching the client to a common channel; S2, broadcasting an inquiry for a handled service kind, acquiring a voice answer of the client, extracting key words in the voice answer, and determining kind of the handled service of the client; and S3, determining the priority of the client according to the kind of the handled service of the client, and adjusting position of the client in a queue. The method of the invention settles problems of high loss of some clients, customer experience reduction and loss of some potential important client caused by queuing of all clients according to a time sequence after telephone end clients select a man service.

Owner:SICHUAN XW BANK CO LTD

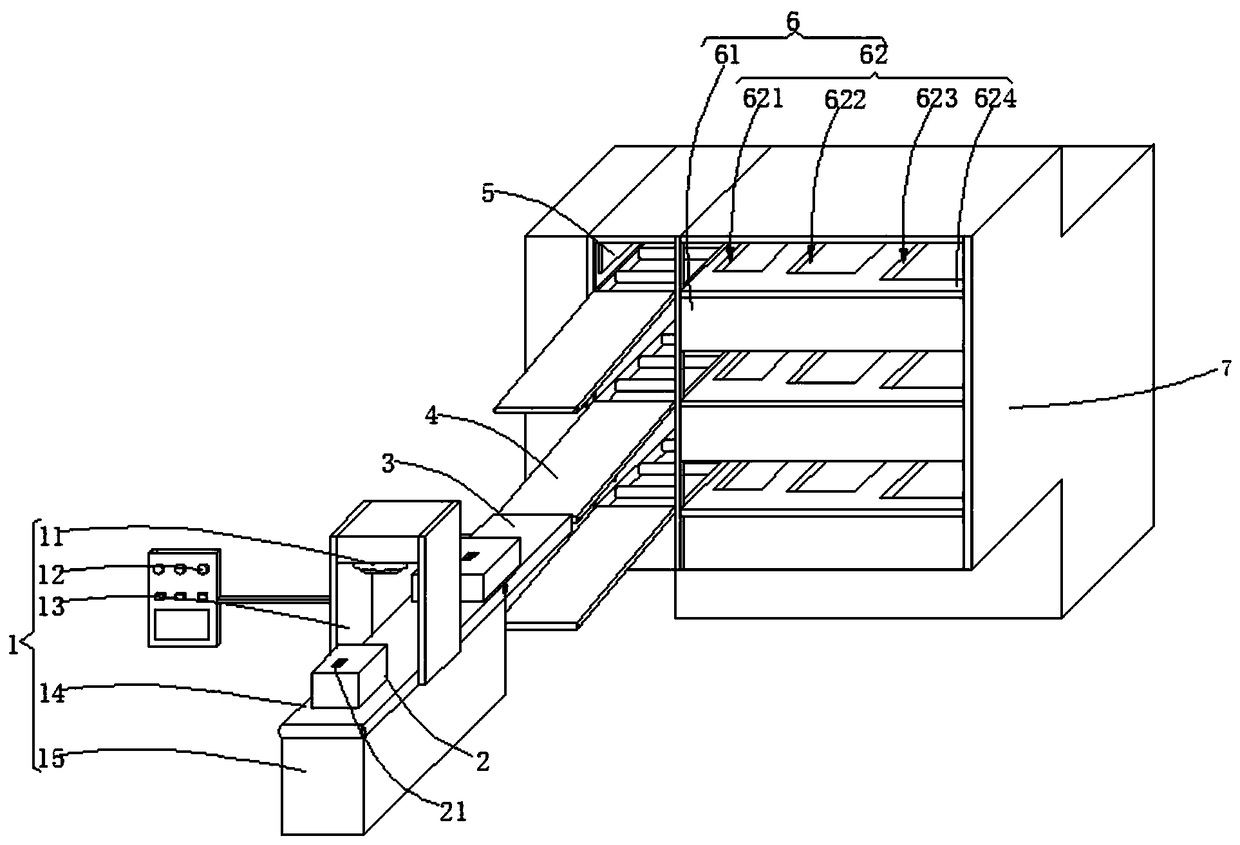

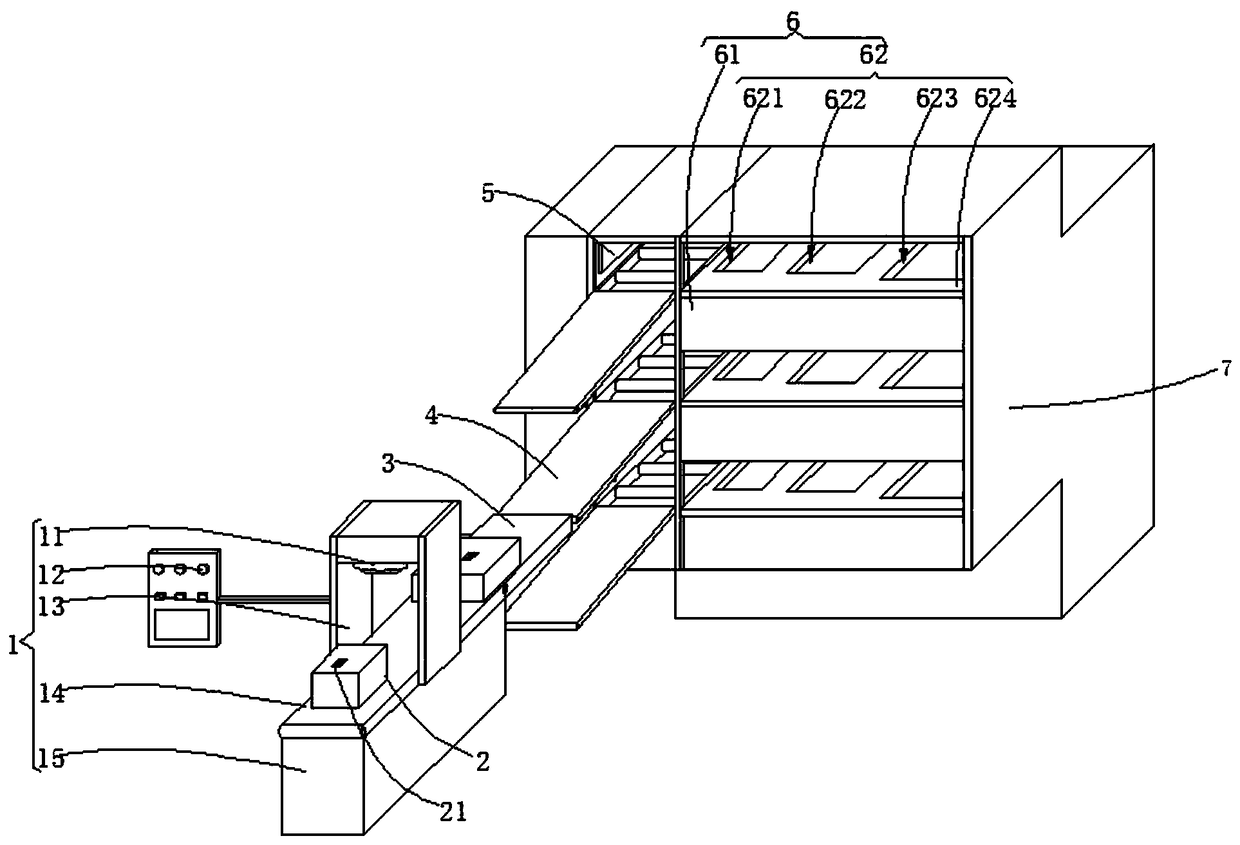

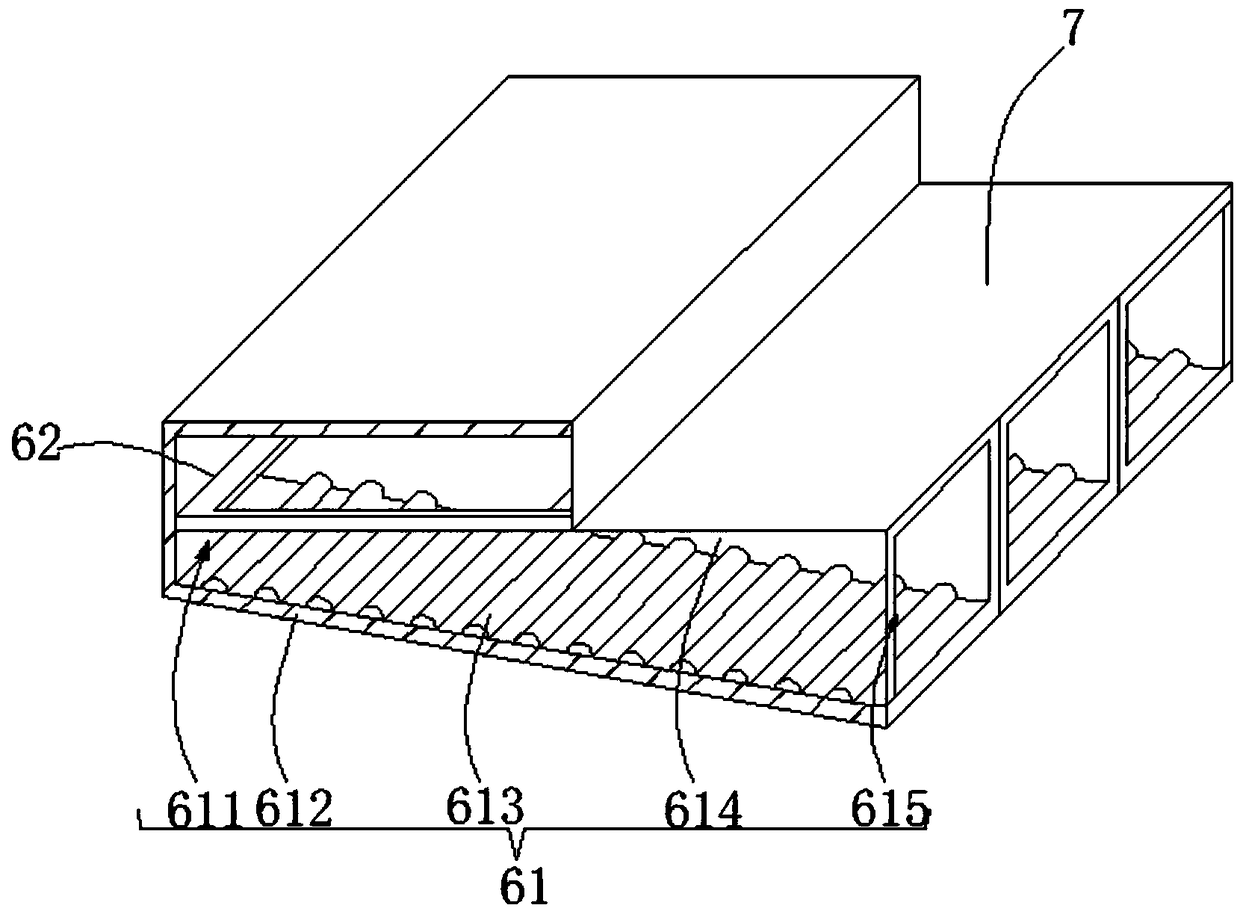

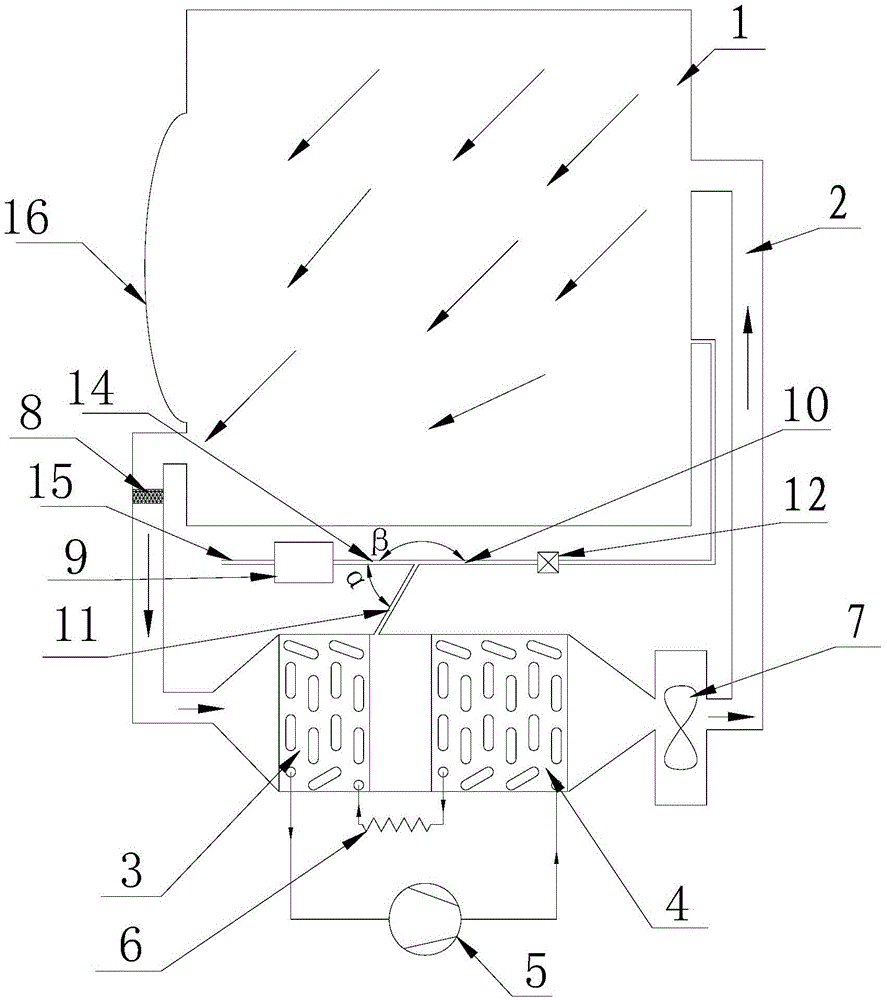

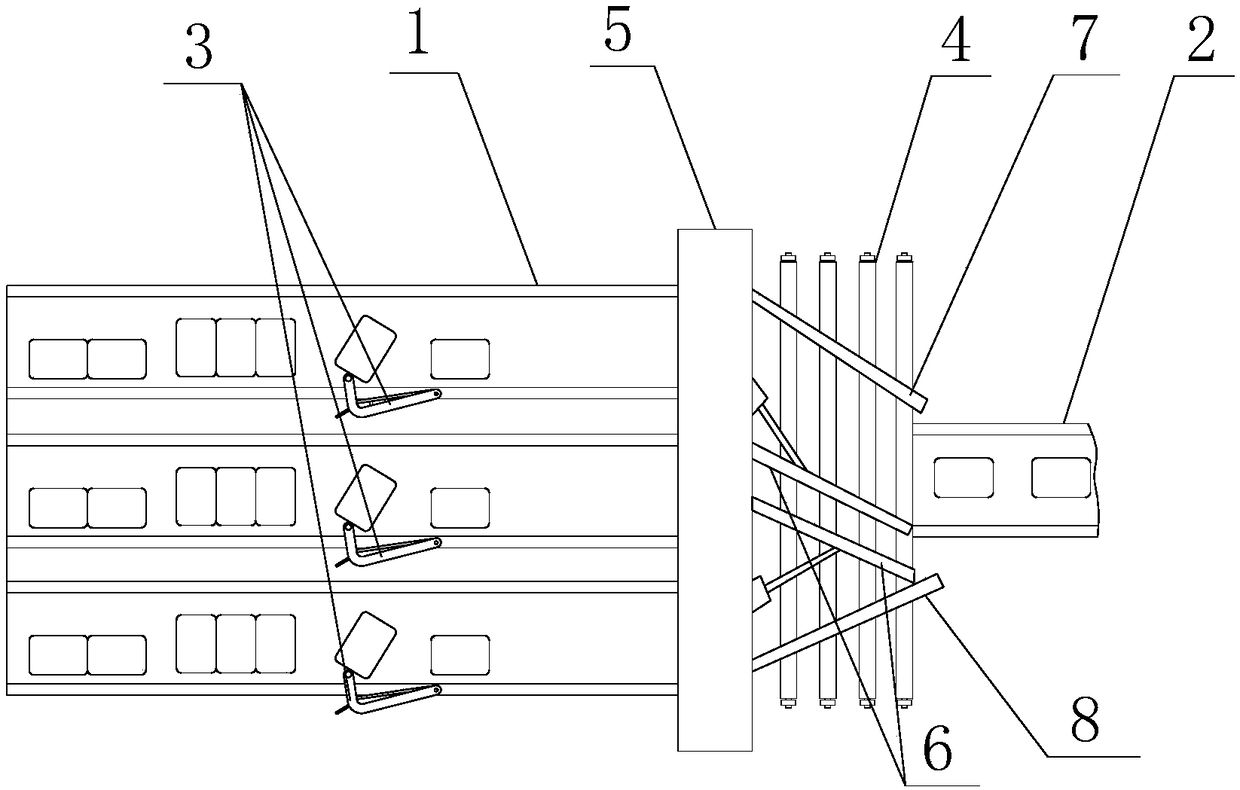

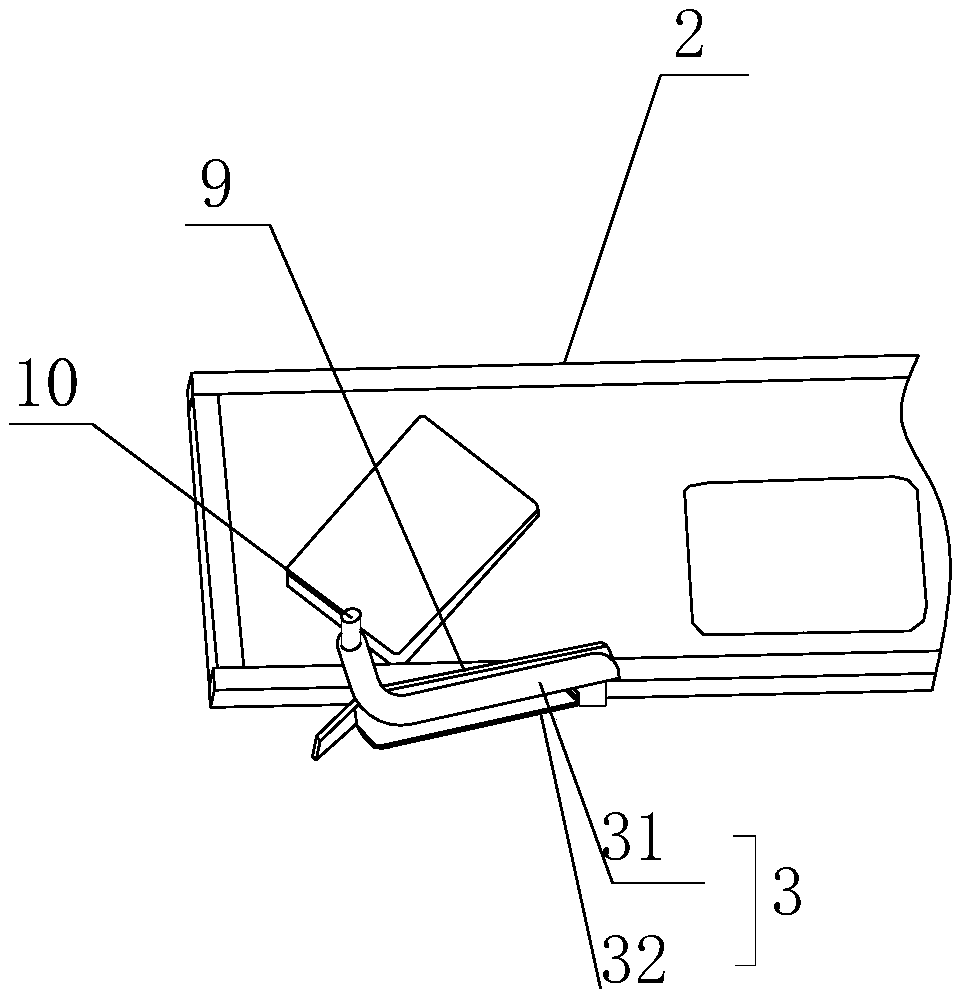

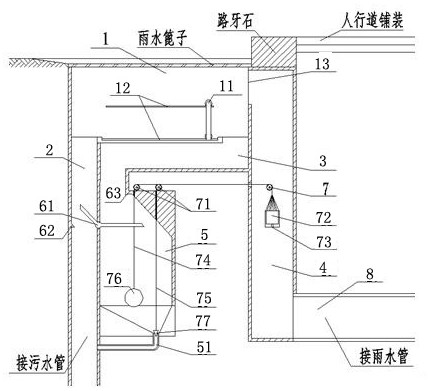

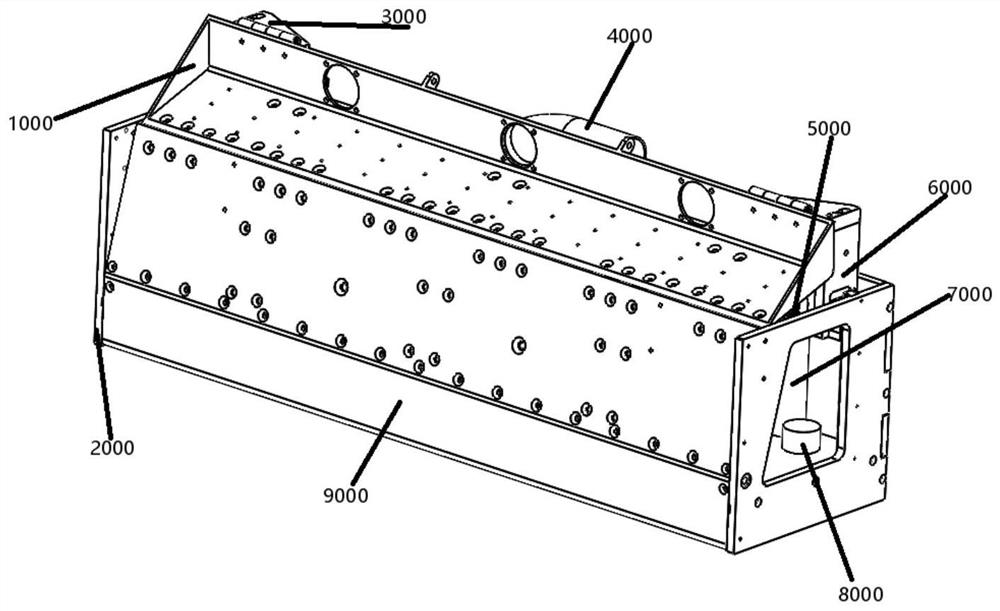

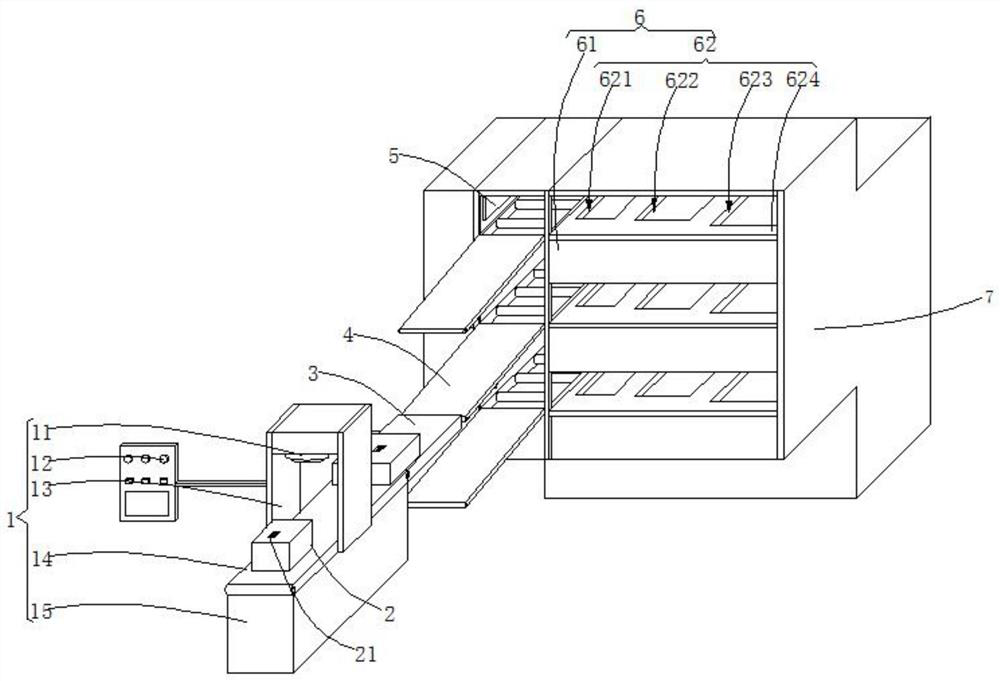

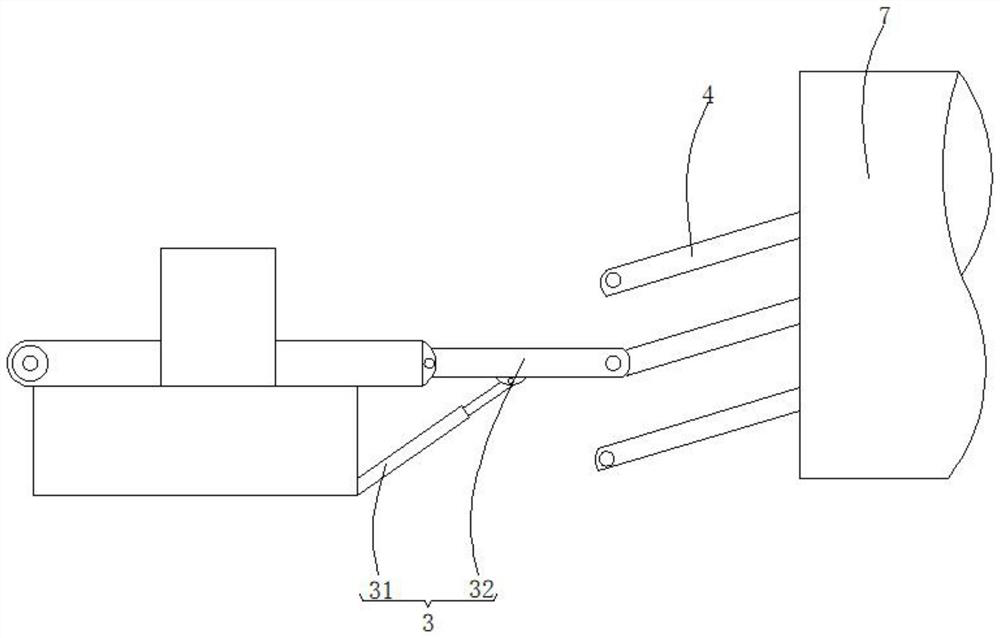

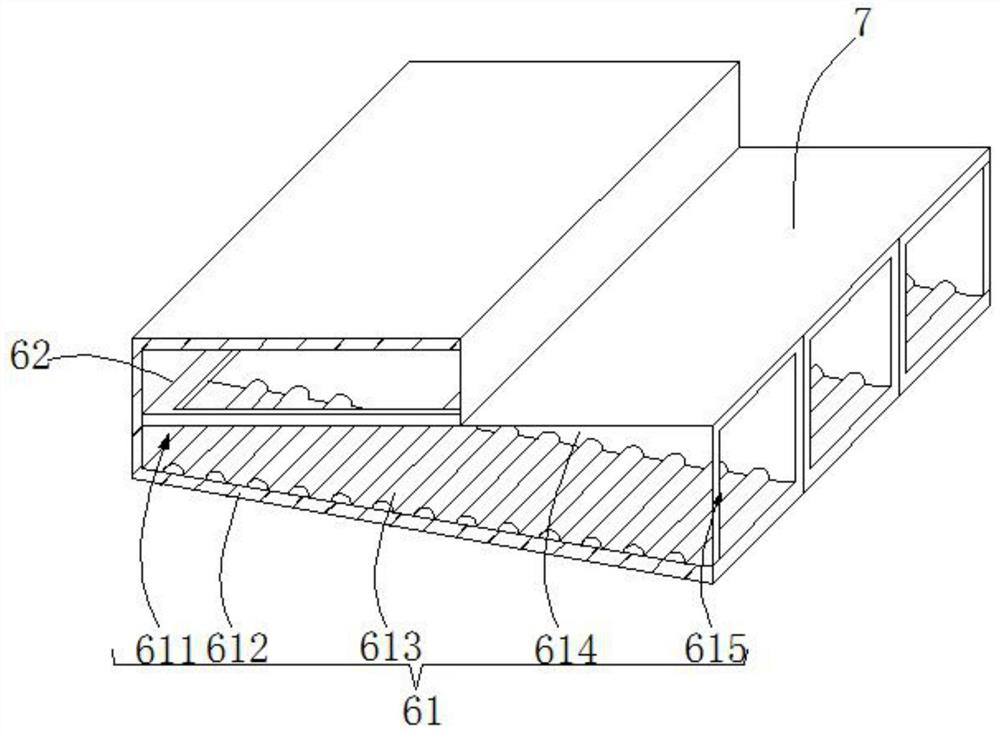

Warehouse logistics sorting system

ActiveCN108636816AEasy to manageEasy to stack and stack neatlyCo-operative working arrangementsSortingTransfer mechanismLogistics management

The invention relates to the field of logistics, in particular to a warehouse logistics sorting system. The warehouse logistics sorting system comprises a detection mechanism, a logistics box, a transferring mechanism, third conveying belts, a pushing mechanism, sorting mechanisms and a processing tank; and the pushing mechanism can achieve sorting and outputting by pushing the logistics box intothe sorting mechanisms. The multiple layers of sorting mechanisms are arranged vertically, each layer corresponds to a specific target area, when objects are sorted, a second conveying belt is controlled to rotate to an inlet of the corresponding third conveying belt according to the destination where packages need to reach, and automatic distribution of the objects of different areas to differentlayers of the sorting mechanisms is achieved; and when the objects are output, the objects can be thrown into a discharging outlet corresponding to the objects according to the size of the objects, loading and unloading are directly conducted according to the size of the objects during container packaging conveniently, tidy piling and stacking of the objects are facilitated at the same time, small objects are prevented from being lost and leaked, and the object sorting and managing speed is increased.

Owner:深圳市泰嘉物流有限公司

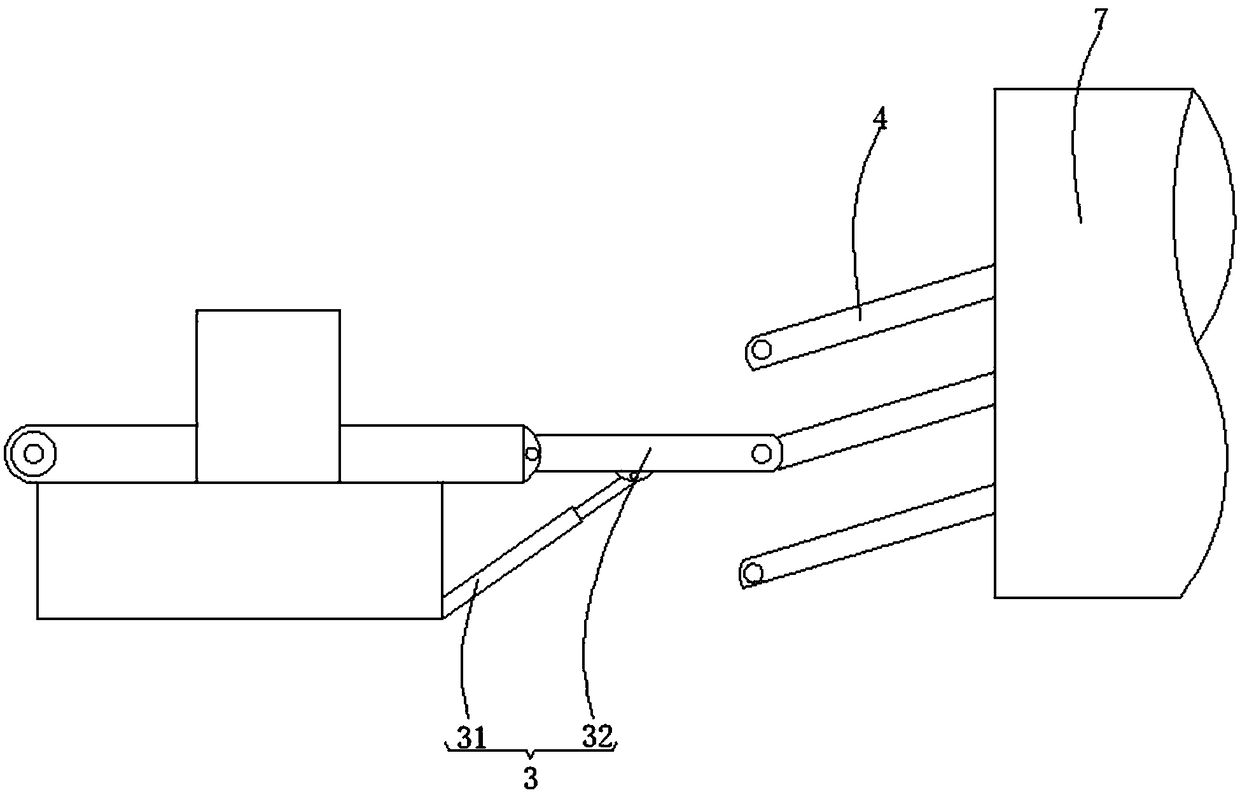

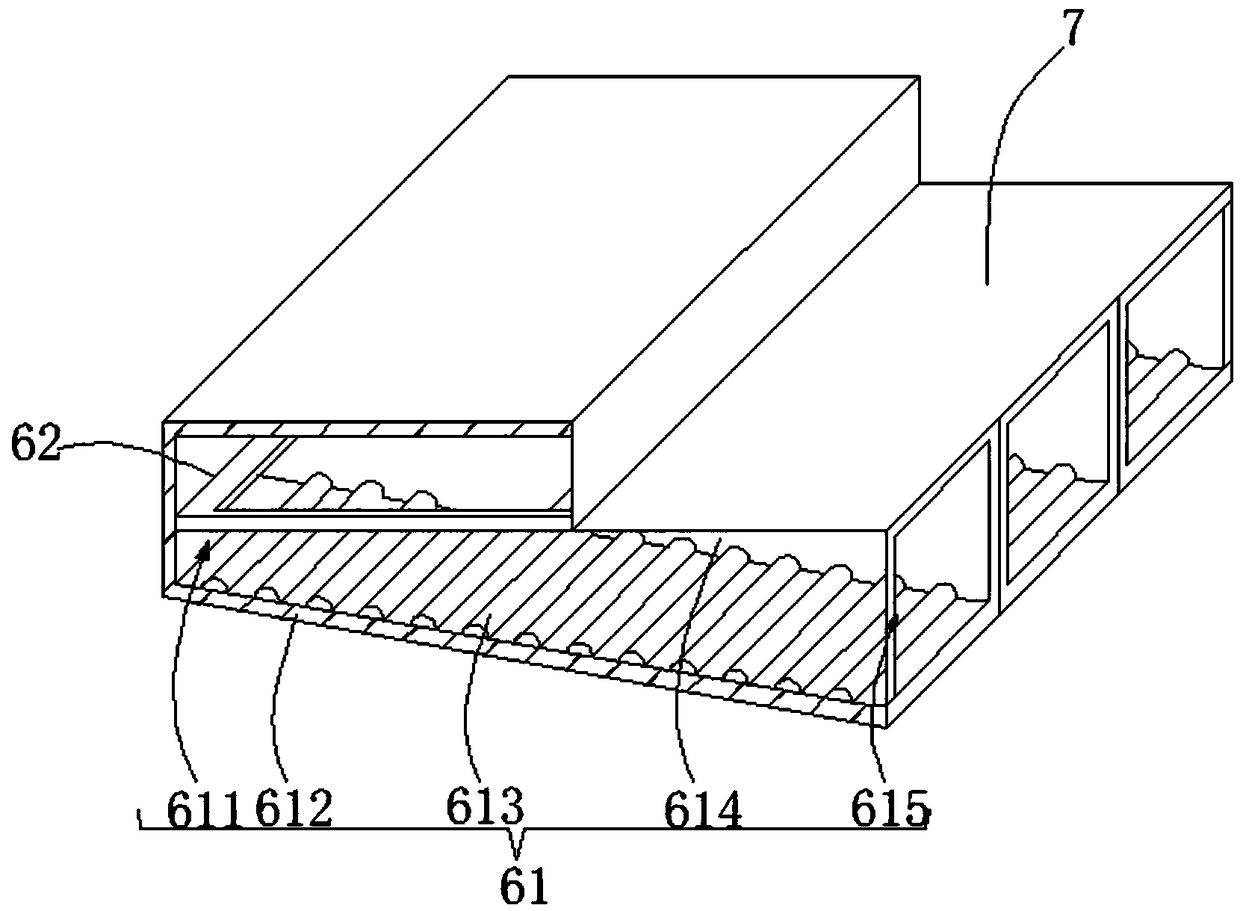

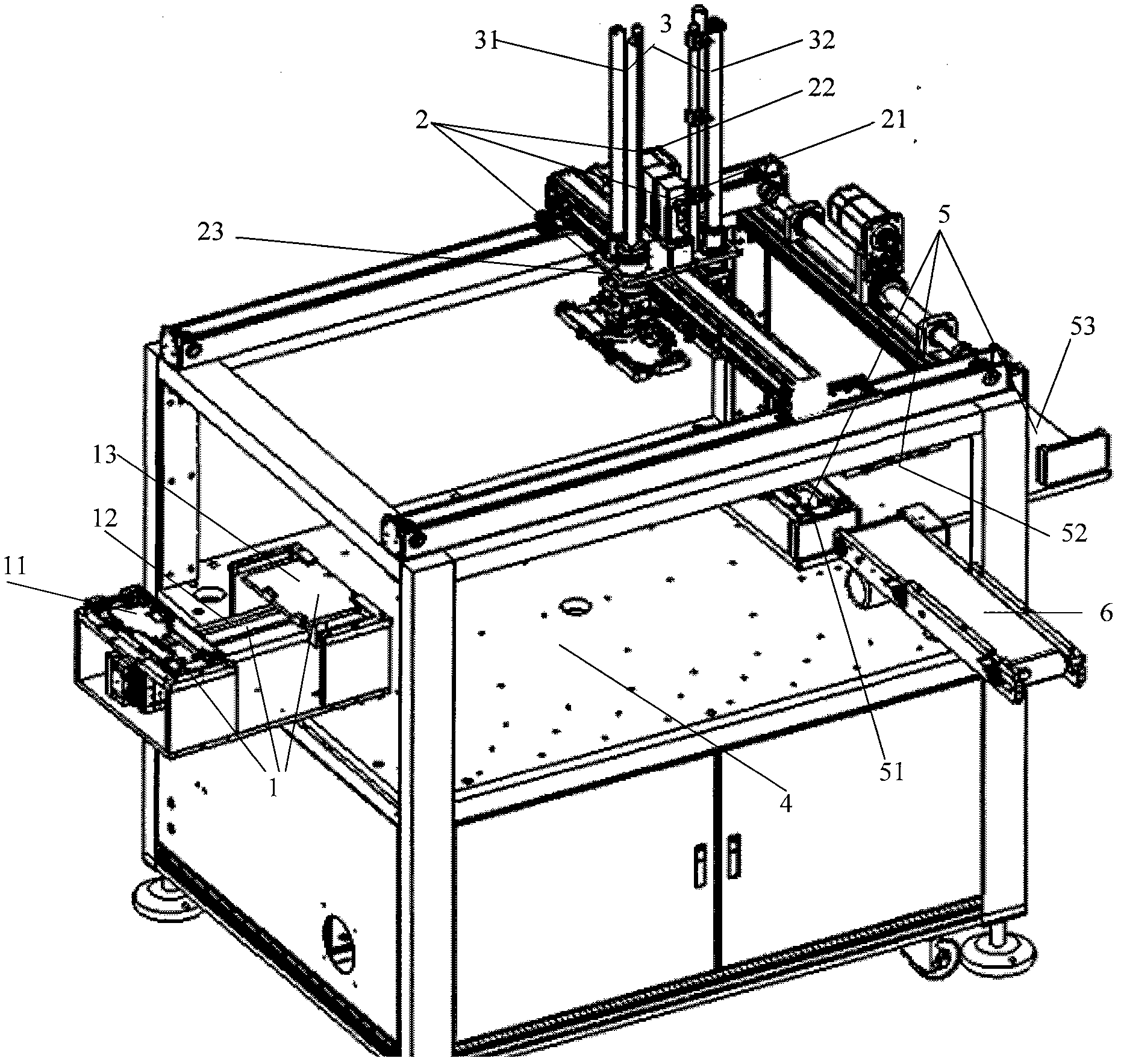

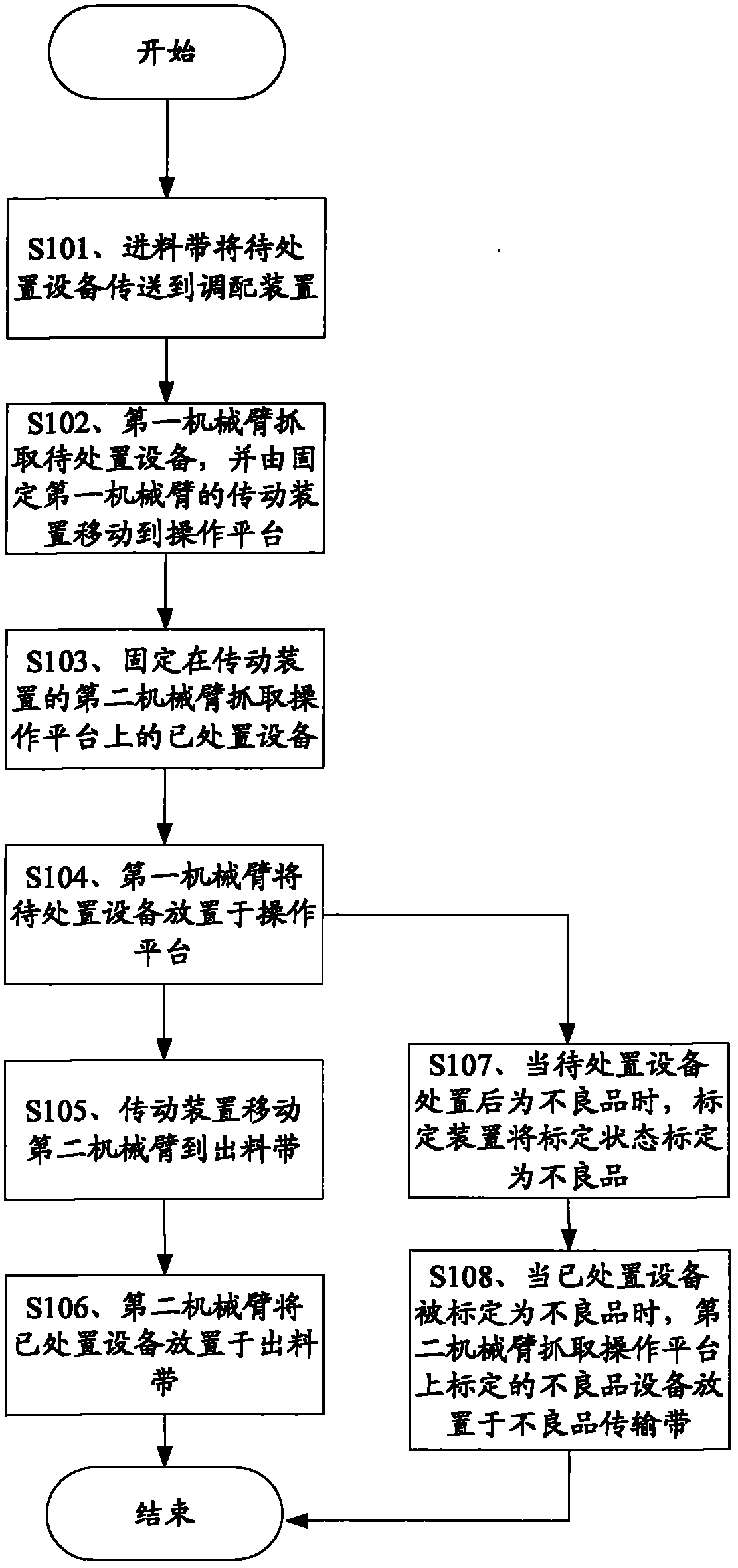

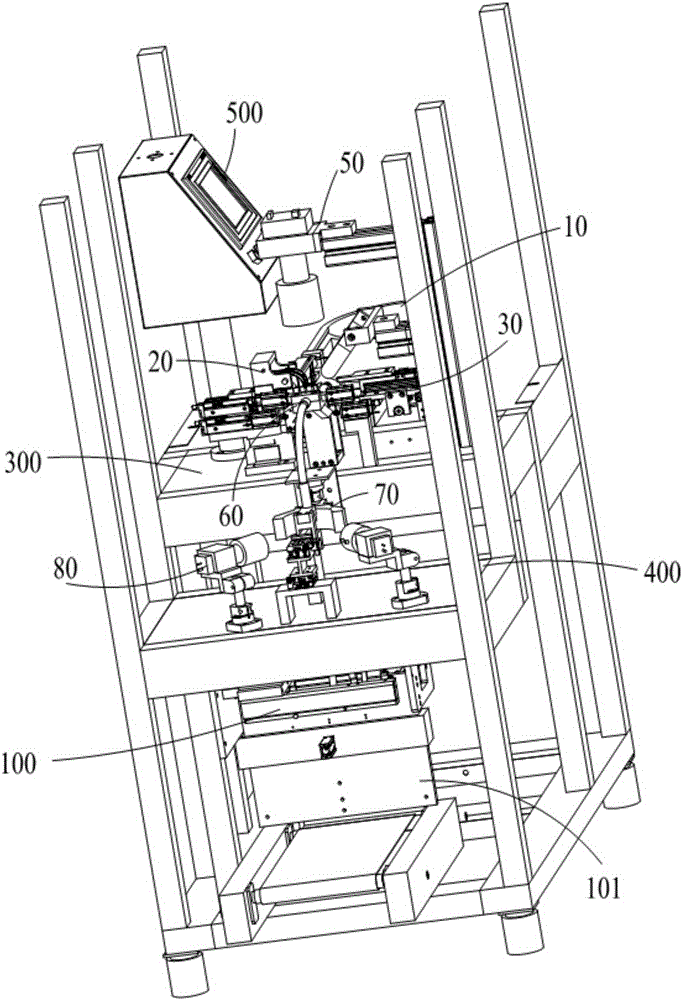

Production line deployment device and production line deployment method

The invention provides a production line deployment device which comprises a feeding belt, a transmission device, at least two mechanical arms, an operating platform and a discharge belt, wherein the feeding belt is connected with the operating platform, and is used for transmitting a device to be treated to one side of the operating platform; the two mechanical arms are fixed on the same transmission device, and are driven to move among the feeding belt, the operating platform and the discharge belt by the transmission device; the first mechanism arm is used for clamping the device on the feeding belt and arranging on the device on the operating platform; the second mechanism arm is used for clamping the device on the operating platform and arranging the device on the discharge belt; and the discharge belt is connected with the operating platform and is used for transmitting the treated device into other devices. The embodiment of the invention also provides a corresponding method. According to the production line deployment device, the device to be tested is only needed to be placed on a front locating platform manually, and the devices which are marked to be rejects can be automatically shunted, so that automation can be realized both in the processes of feeding and discharging, and a great deal of manpower can be saved.

Owner:赵跃庆

Warehouse logistics transfer method

The invention relates to the field of logistics, in particular to a warehouse logistics transfer method. A sorting device employed in the method comprises a detection mechanism, a logistics box, a transfer mechanism, a third conveying belt, a push mechanism, a sorting mechanism and a treatment box body; and the push mechanism can push the logistics box into the sorting mechanism for sorting and outputting. The sorting mechanism is provided with multiple layers up and down, each layer corresponds to a specific destination area, and a second conveying belt is controlled to rotate to the inlet position of the corresponding third conveying belt according to the destination which packages arrive at, so that goods in different areas are automatically distributed to different layers of the sorting mechanism; and when the goods are output, the goods are put into the corresponding feeding port according to the size, so that the goods can be directly loaded and unloaded according to the size during packaging, the goods are piled and stacked tidily, loss and leakage of small goods are avoided, and the sorting and management rate of the good can be increased.

Owner:深圳市泰际信息科技有限公司

Method for initiating self-help voice interaction for customer service in line

InactiveCN107302639AImprove accuracySatisfaction experienceSpecial service for subscribersSpeech recognitionSpeech soundData library

The invention discloses a method for initiating self-help voice interaction for customer service in line, and relates to the technical field of the communication. The method comprises the following steps: S1, acquiring a phone number of a call customer, comparing the phone of the customer with a VIP customer phone database, detecting whether the customer is the VIP customer through the phone number, if the customer is the VIP customer, switching the customer to a VIP channel; if the customer is not the VIP customer, switching the customer to a common channel; S2, broadcasting the inquiry of the handled business type to acquire a voice answer of the customer, extracting a keyword in the voice answer, and judging the class of the business that customer needs to handle; S3, comprehensively analyzing according to the class of the business that customer needs to handle and the current line number, and then prompting the customer to switch to the self-help voice handling or continuously stay on the queue line. The problems that the customer experience degree is bad and the band is easy to lose some potential important customers since the present manual service agent channel is large in line pressure are solved by using the method disclosed by the invention.

Owner:SICHUAN XW BANK CO LTD

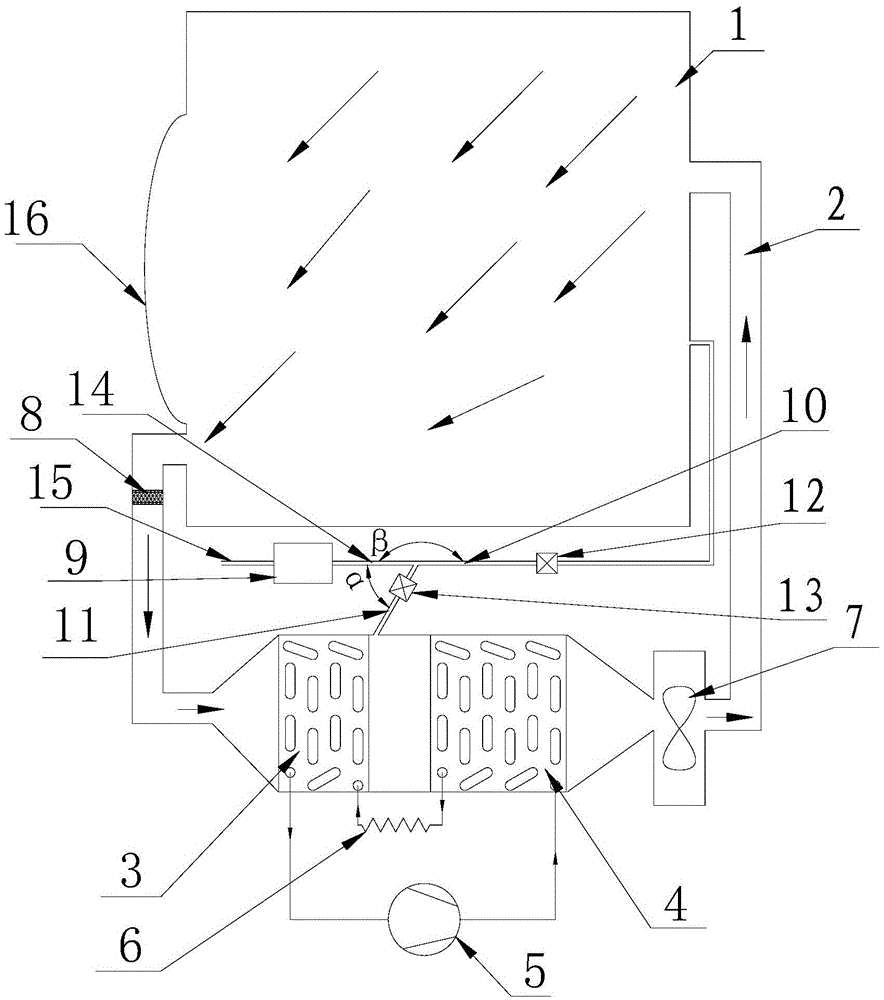

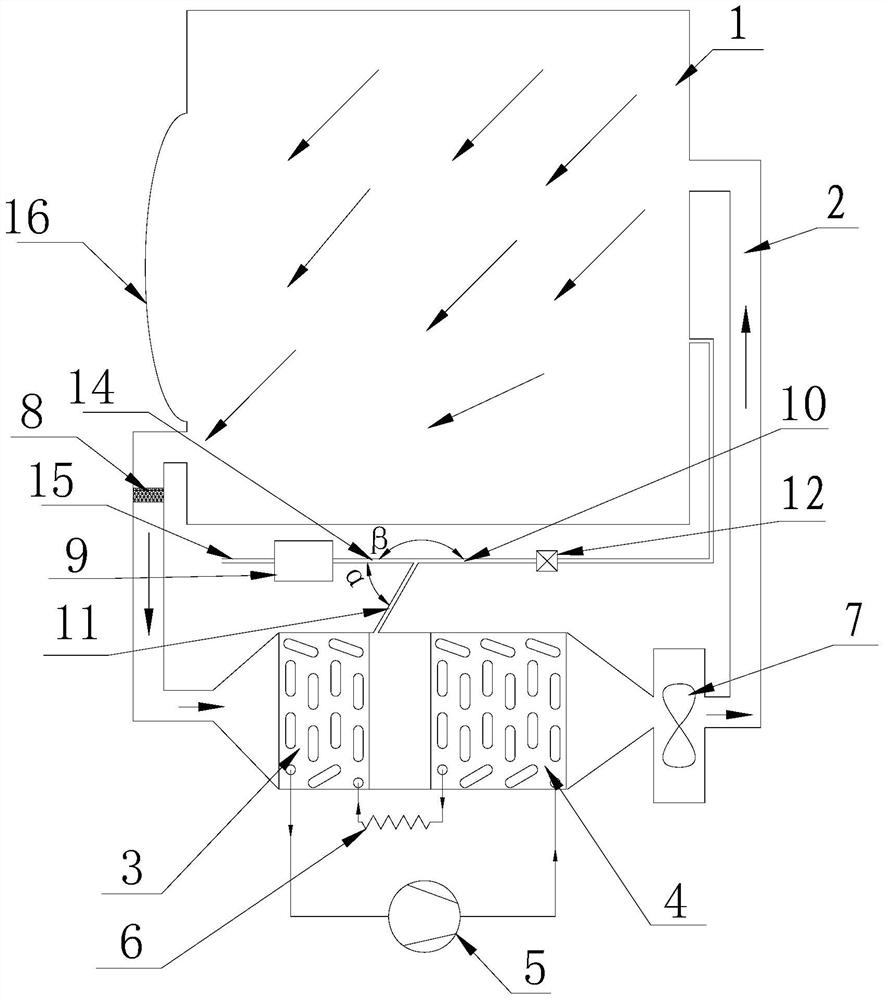

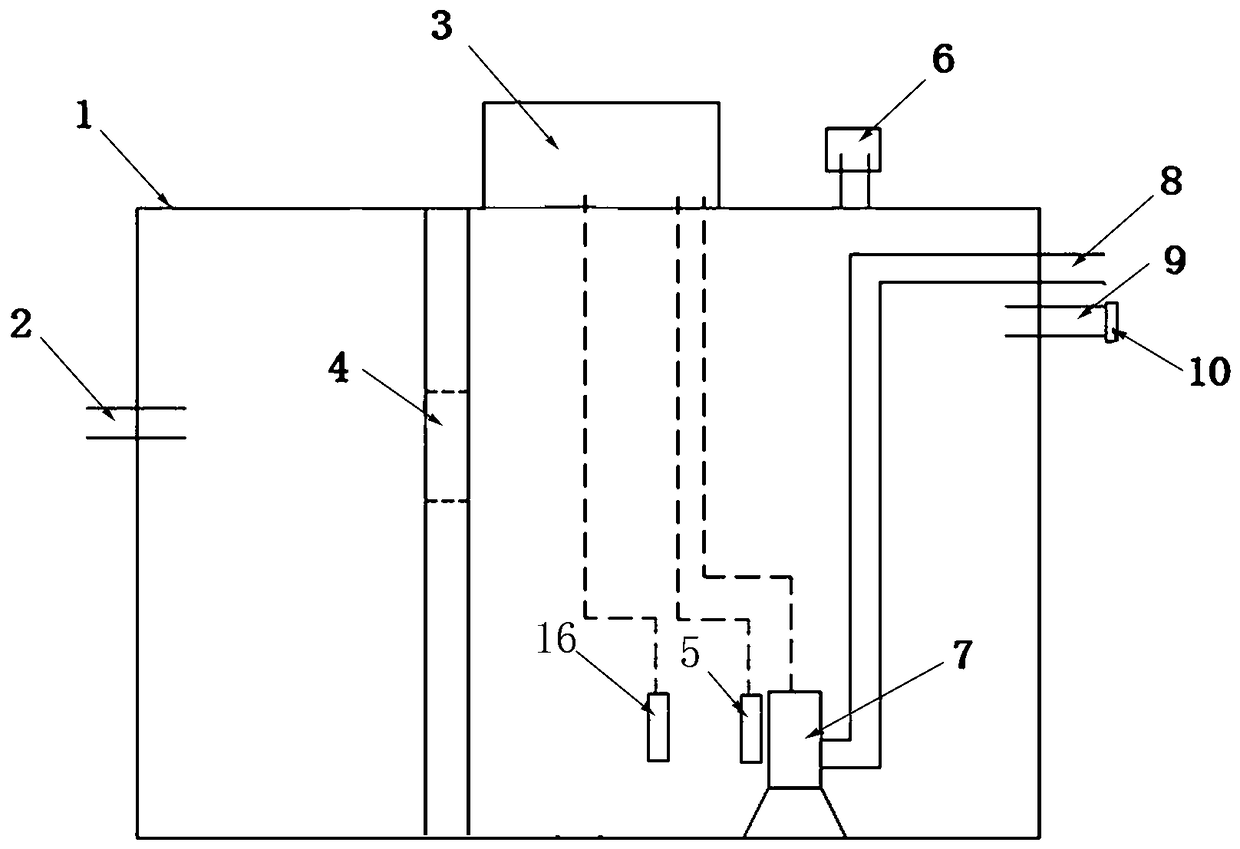

Clothes dryer with steam function and steam control method

ActiveCN106592179AReduce the amount requiredAvoid squirtingTextiles and paperLaundry driersWater vaporEngineering

The invention relates to a clothes dryer with a steam function. The clothes dryer is provided with a steam generator. An air outlet of the steam generator is communicated with an outer barrel and a drying wind path through pipes, so steam flows to the outer barrel and / or the drying wind path in a controllable manner. The invention also relates to a steam control method of the clothes dryer. In a normal steam treating process of the clothes dryer on clothes, at least most water vapor generated by the steam generator flows into the outer barrel. When a door body on a clothes putting opening of the clothes dryer is open, at least most water vapor generated by the steam generator flows into the drying wind path. Through the above device and method, steam generated by the steam generator flows to the outer barrel and / or the drying wind path in a controllable manner, preventing occurrence that large amount of steam sprays from an opening formed by opening of the door body and waste heat hurts users caused by steam flowing into the outer barrel after a user opens the door body. The clothes dryer is simple in structure and substantial in effect, and is suitable for popularization and application.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

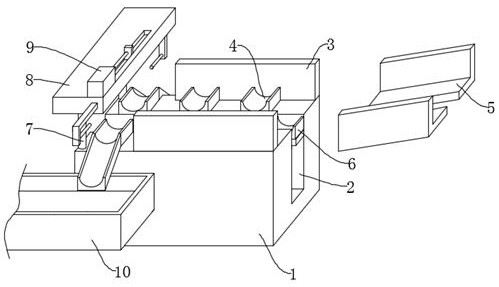

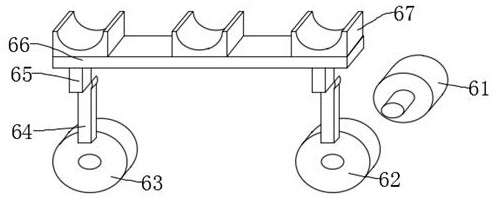

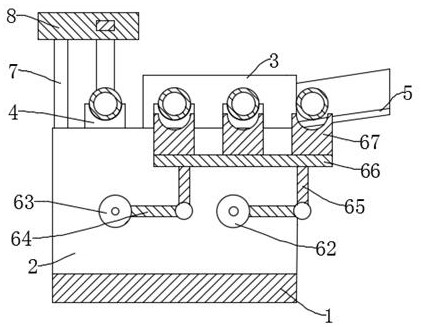

Conveying mechanism for can processing

InactiveCN111960063AEasy to sieveRealize automatic adjustmentConveyorsConveyor partsStructural engineeringBottle

The invention discloses a conveying mechanism for can processing. The conveying mechanism comprises a base, wherein a mounting groove is formed in the middle of the base, multiple positioning seats are mounted in the positions, located at the top of the base, of two sides of the mounting groove, guide plates are mounted on the base, chutes are mounted in the positions, located on the side walls ofthe base, of two sides of the mounting groove, each chute is connected with one end of the corresponding guide plate, a positioning mechanism is mounted between inner walls of the mounting groove, astand column is fixedly mounted at the top of the end, away from the chutes, of the base, a top plate is fixedly mounted at the top of the stand column, a shunting mechanism is mounted on the top plate and directly faces the positioning seats away from the chutes, and conveying belts are mounted on the outer wall of the end, away from the chutes, of the base. According to the conveying mechanism for can processing, canned bottles are conveyed to the chutes through the conveying belts in a unified manner and slide to the side walls of the base along the chutes, the canned bottles are placed onthe positioning seats one by one by the positioning mechanism, positioning for the canned bottles is realized, the canned bottles on the positioning seats away from the chutes are pushed to the conveying belts on the two sides of the base by the shunting mechanism, so that the opening direction of the canned bottles on each conveying belt are consistent, the canned bottles are automatically adjusted and conveyed, and subsequent processing and production are facilitated.

Owner:宿州皇冠食品有限公司

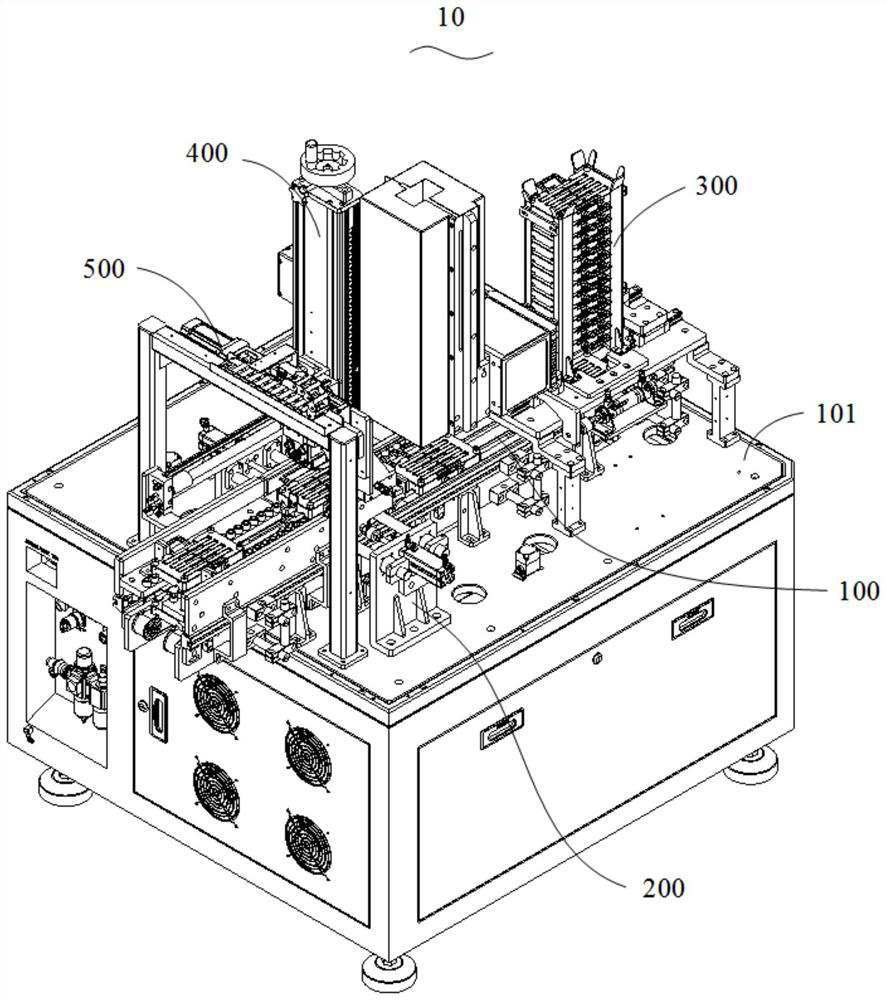

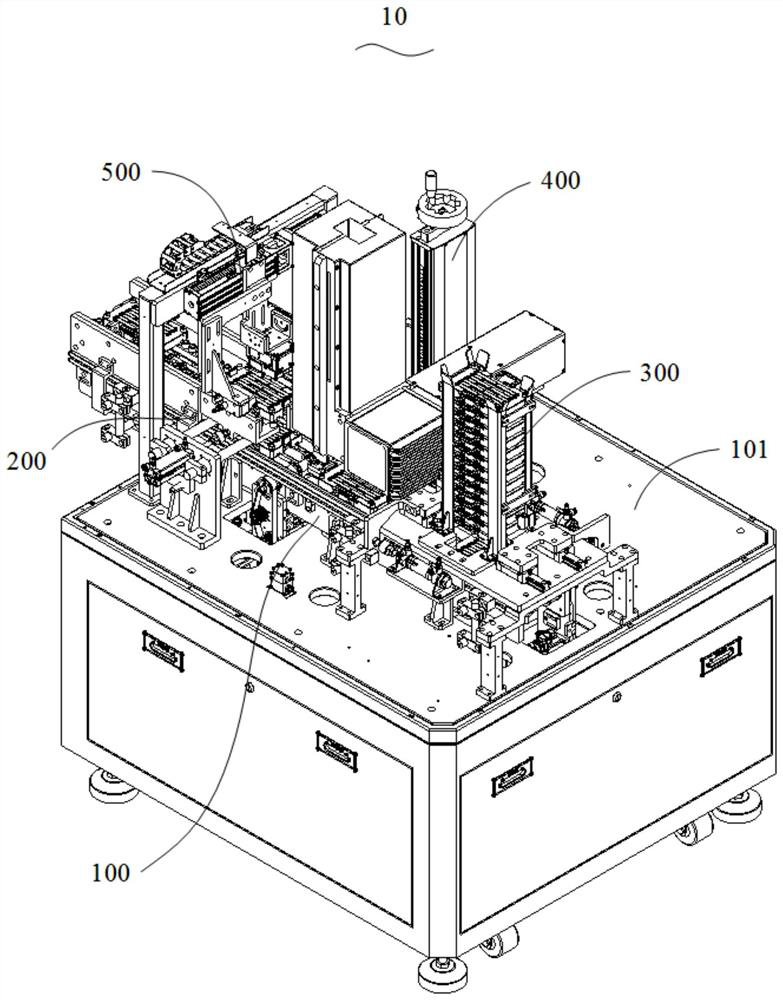

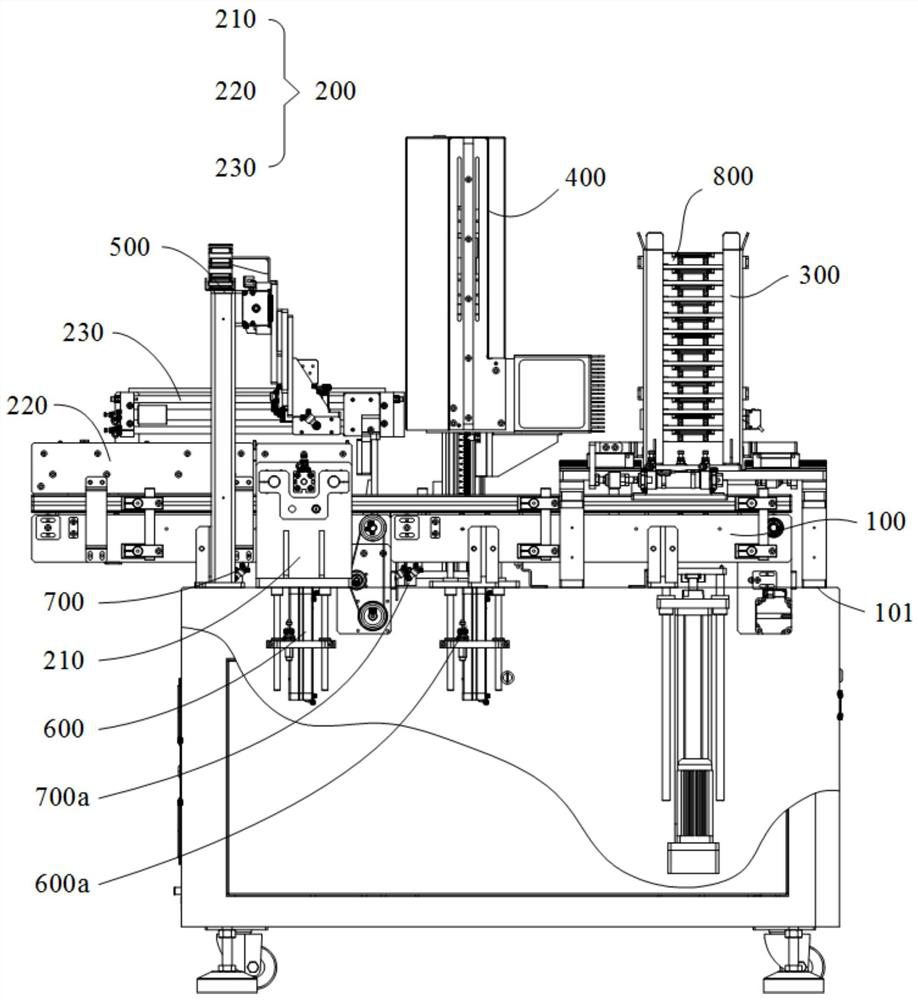

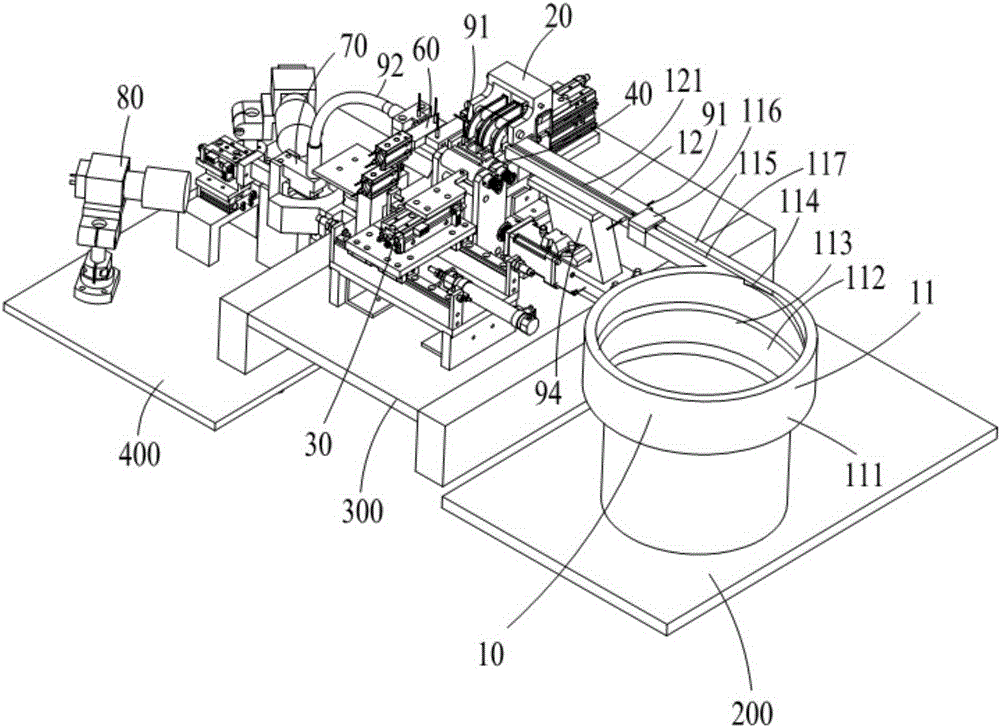

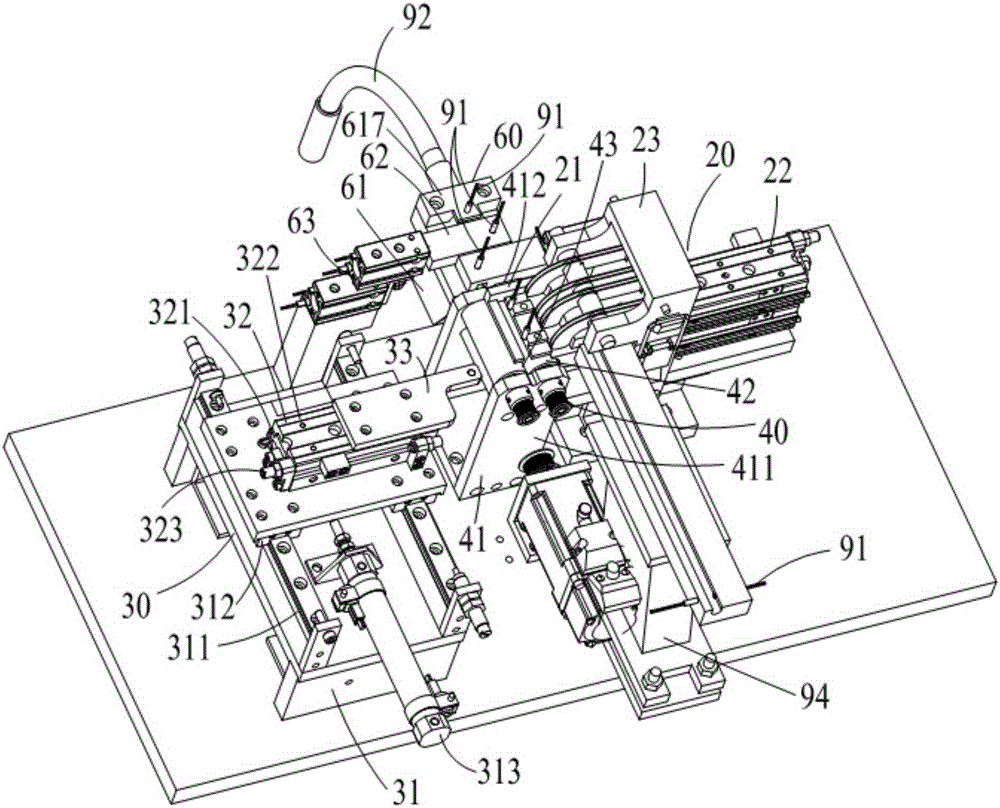

Laser marking equipment

PendingCN112810322ARealize automatic shuntIncrease productivityTypewritersSortingMarking outEngineering

The invention discloses laser marking equipment. The laser marking equipment comprises a marking machine main body, a conveying mechanism and a sorting mechanism. The marking machine main body is provided with a feeding station, a marking station and a detection station, and the marking machine main body is used for carrying out laser coding on products at the marking station to form identification codes, scanning the identification codes of the products at the detection station and confirming whether the identification codes are qualified or not. The conveying mechanism is used for conveying the products from the feeding station to the marking station and the detection station in sequence. When the marking machine main body confirms that the identification codes of the products at the detection station are qualified, the conveying mechanism is further used for conveying the products with the qualified identification codes to a qualified product discharging position. The sorting mechanism is used for sorting out the products with unqualified identification codes and conveying the products to an unqualified product discharging position when the marking machine main body confirms that the identification codes of the products at the detection station are unqualified. According to the technical scheme, automatic separation of qualified products and unqualified products can be achieved, and the working efficiency is improved.

Owner:SHENZHEN TETELASER TECH CO LTD

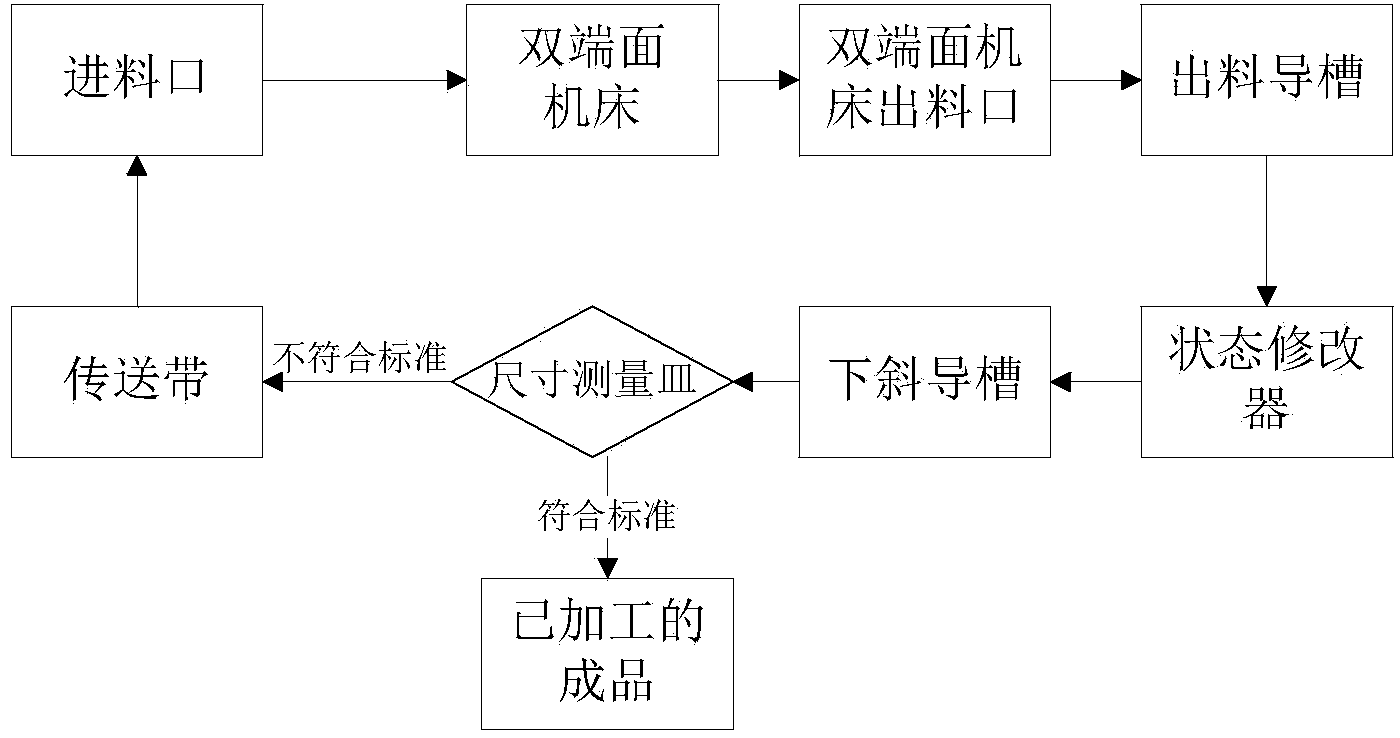

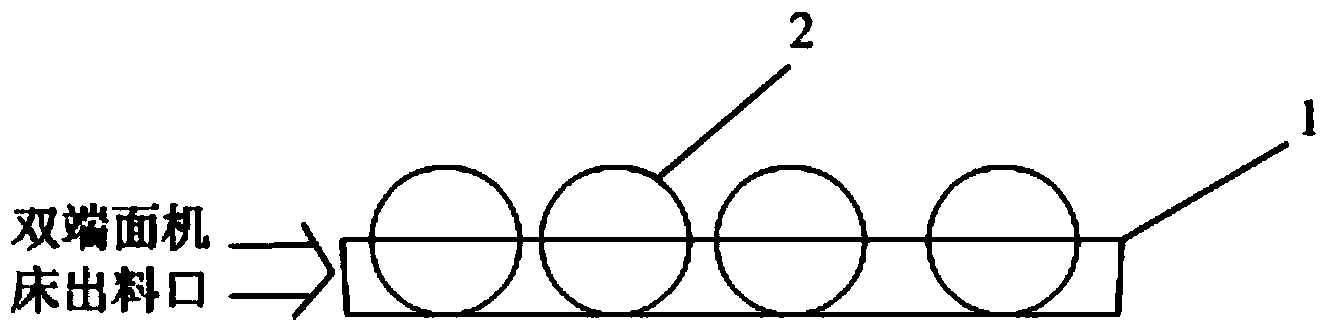

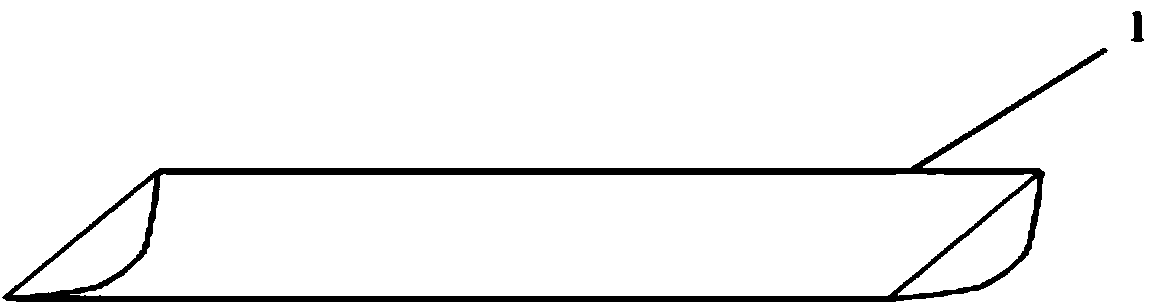

Discharge detecting device of bearing double-end-face processing machine tool

InactiveCN103894925AImprove machining accuracyImprove processing qualityGrinding feed controlGrinding feedersMachine toolProcessing accuracy

The invention discloses a discharge detecting device of a bearing double-end-face processing machine tool. The discharge detecting device comprises an input guide rail connected with a discharge end of the double-end-face processing machine tool, a measuring vessel used for measuring bearing size, a first output guide rail and a second output guide rail, and the input guide rail comprises a guide unit used for guiding a rolling state of bearings to be a state of sliding along end faces. The discharge detecting device has the advantages that automatic feeding is realized; due to designed structure of the measuring vessel, automatic diverging of qualified products and unqualified products is realized; the guide rail used for conveying the unqualified products is reconnected with an input end of the machine tool, so that reprocessing of defective products is realized, and production cost is lowered; the discharge detecting device is easy and simple to operate, so that high-efficiency full automation of a bearing double-end-face discharge link is realized, processing accuracy is improved, manual work and manpower are reduced, bearing processing and quality are improved, number of repeated secondary processing is reduced, and automated management of bearing double-end-face processing discharge is realized.

Owner:SHANGHAI NORMAL UNIVERSITY

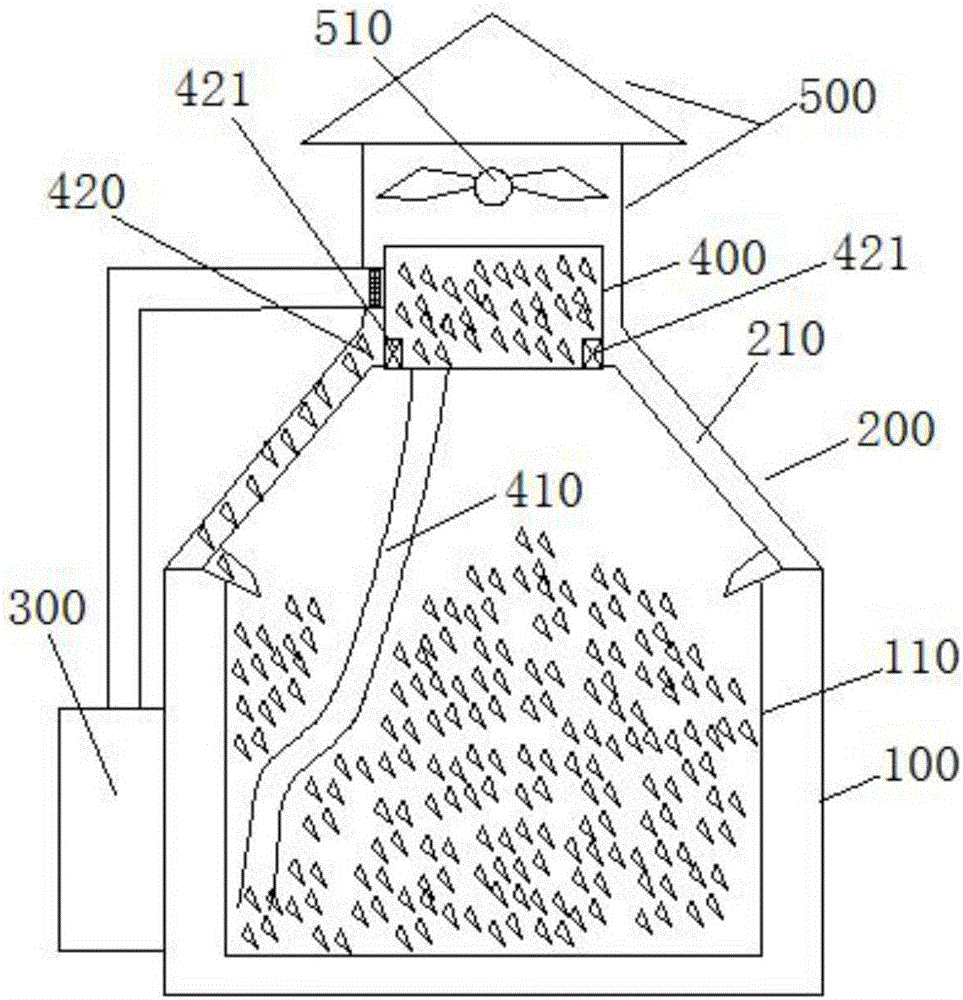

Intelligent grain storage device

PendingCN106576632ATimely exclusionAchieve the technical effect of chasing light and dryingAgriculture tools and machinesClimate change adaptationEngineeringAir drying

The invention discloses an intelligent grain storage device, having a technical advantage of full-automatic air drying of grains. The structure of the intelligent grain storage device comprises a bin body, a storage bin arranged in the bin body, a bin top, a negative pressure delivery pump, a measuring bin and an exhaust hood, wherein an air-drying bin is arranged at any side wall of the bin top respectively, and consists of a feed port, a discharge port, a light absorbing plate and a transparent cover covering and locked on the light absorbing plate; the discharge port communicated with the storage bin; the measuring bin is arranged in the bin top; the upper end of the measuring bin is connected with the negative pressure delivery pump by virtue of an extraction opening provided with a filter screen; the bottom of the measuring bin is connected with a feed pipe communicating with a storage space of the bin body; a level meter is arranged in the measuring bin and is connected with the negative pressure delivery pump through a controller; the lower end of the measuring bin is provided with a material dividing port connected with the feed port of each air-drying bin respectively, and each material dividing port is provided with a material dividing valve respectively; and a draught fan is arranged in the exhaust hood which is arranged right above the bin top. The intelligent grain storage device disclosed by the invention can achieve intelligent air drying.

Owner:赵亦军

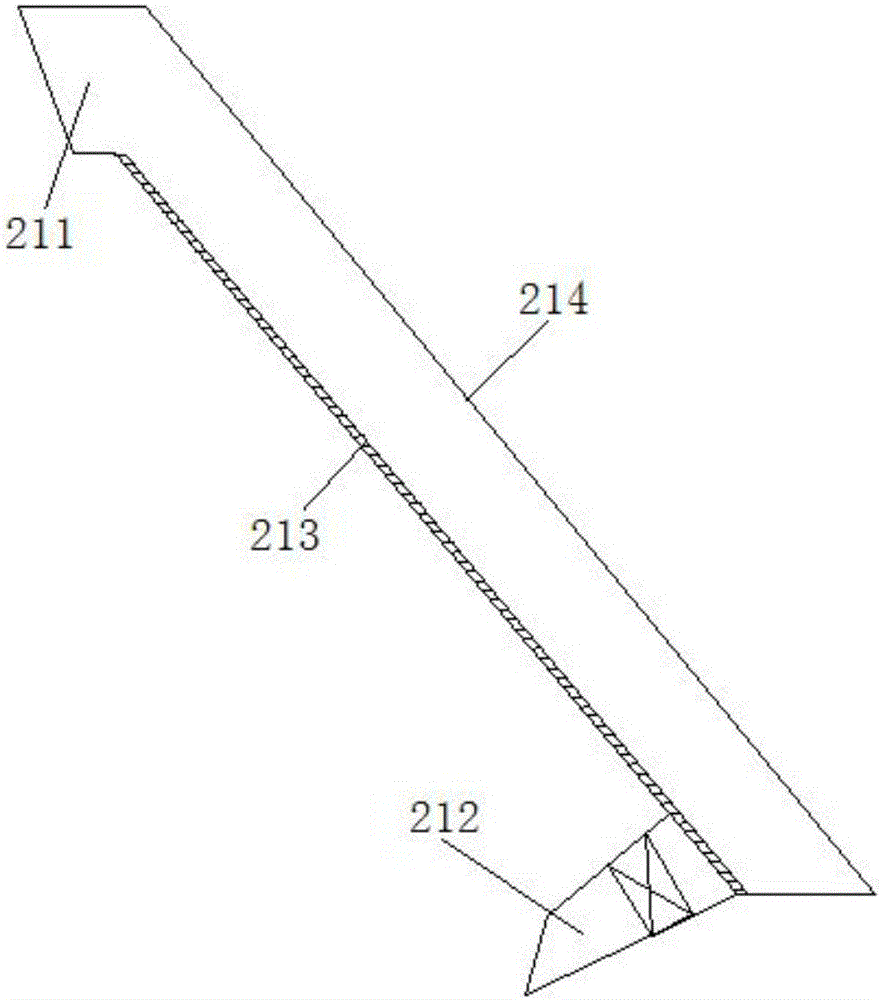

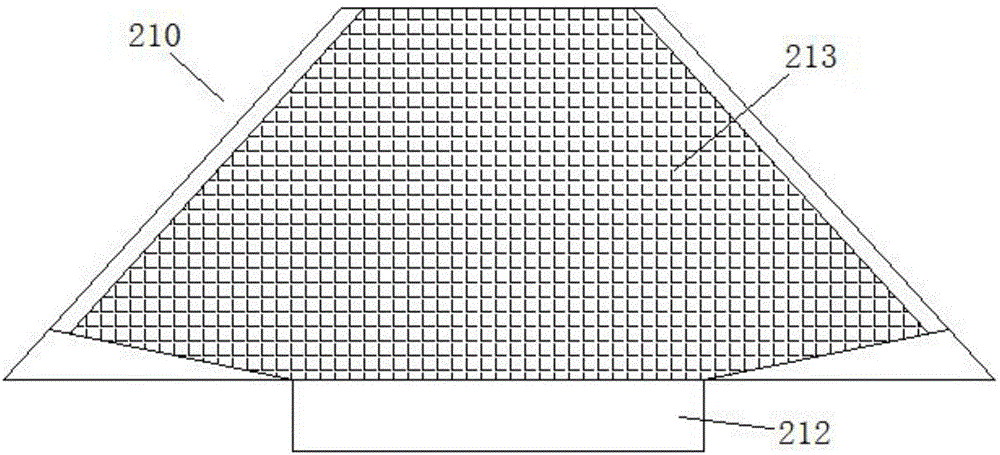

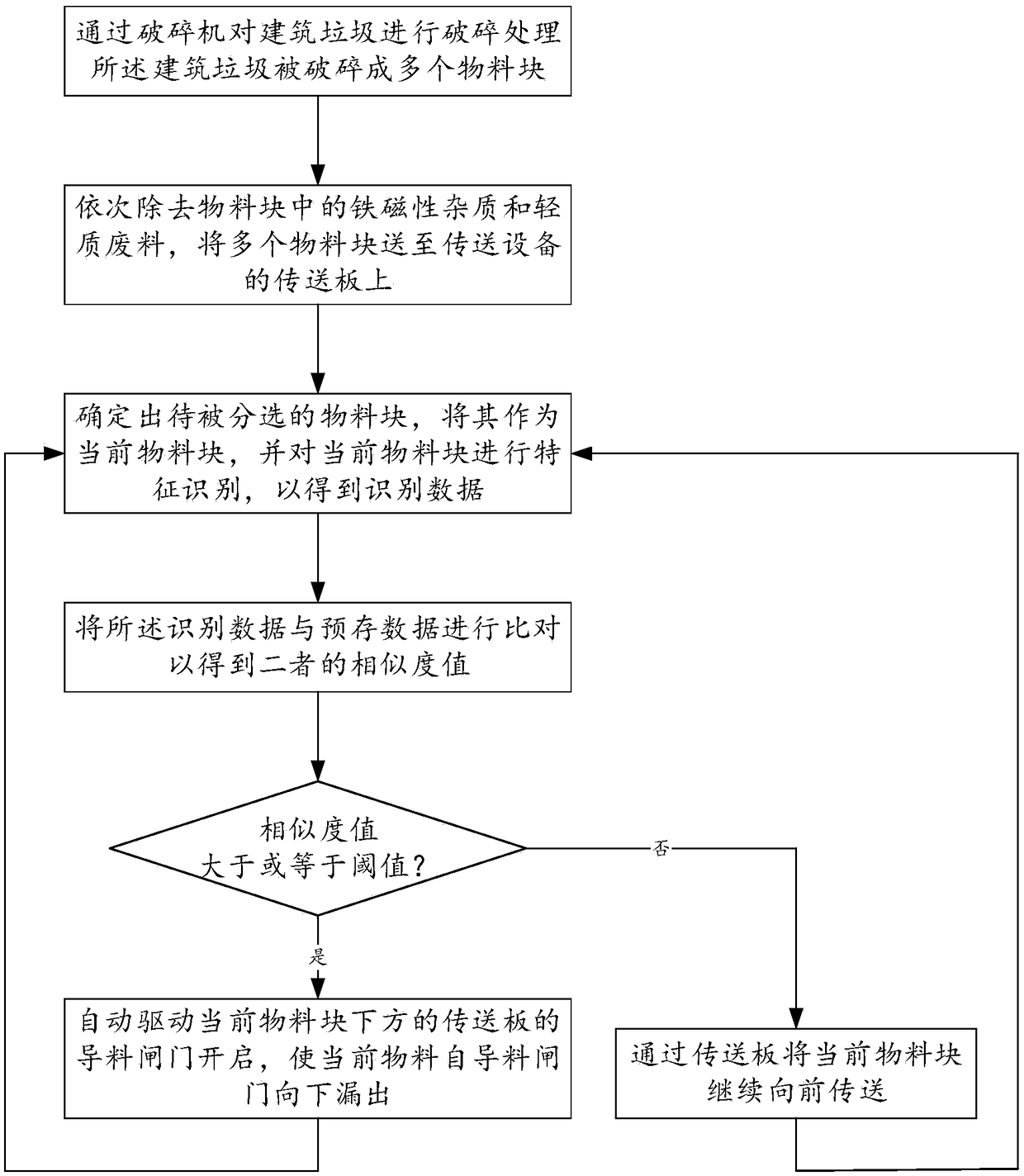

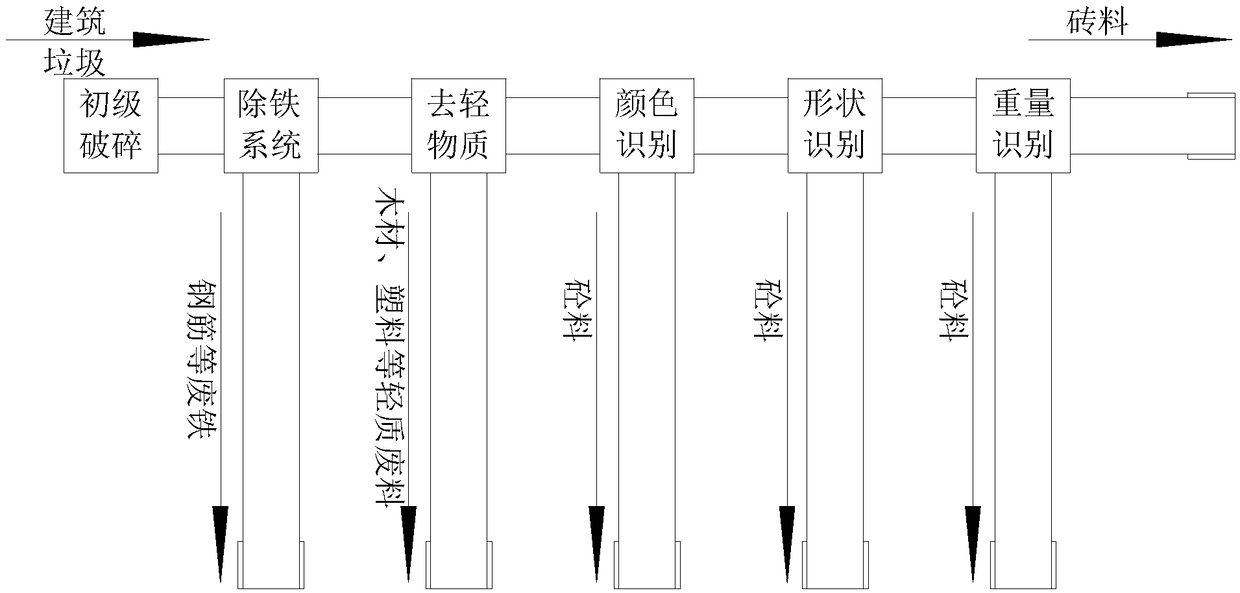

Automatic sorting method for construction waste

PendingCN108837936AAchieve separationAvoid personal harmCleaning using gasesGrain treatmentsBrickEngineering

The invention discloses an automatic sorting method for construction waste. The automatic sorting method comprises the following steps that firstly, the construction waste is crushed into material blocks; secondly, ferromagnetic impurities and light waste materials are removed, and the material blocks are conveyed to a conveying plate of conveying equipment; thirdly, feature identification is carried out on the current material blocks to obtain identification data; fourthly, the identification data are compared with the pre-stored data, and the similarity value of the identification data and the pre-stored data is obtained; if the similarity value is greater than or equal to the threshold value, the fifth step is executed; and otherwise, the sixth step is executed; fifthly, a material guide gate of the conveying plate below the current material blocks is driven to open so that the material guide gate can leak the current materials downward and the third step can be executed; and sixthly, the current material blocks are continuously conveyed forward, and the third step is executed. By the adoption of the automatic sorting method for the construction waste, the construction waste canbe effectively identified and sorted, the automatic diversion of brick materials and concrete materials is effectively realized, the sorting efficiency is improved, the harm to workers is avoided, and the labor cost is reduced.

Owner:HEBEI ZHUODA BUILDING MATERIALS RES INST CO LTD

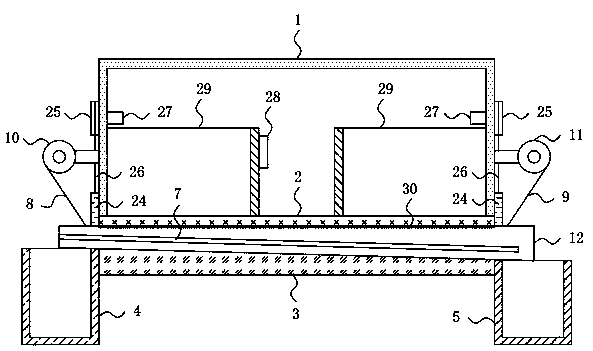

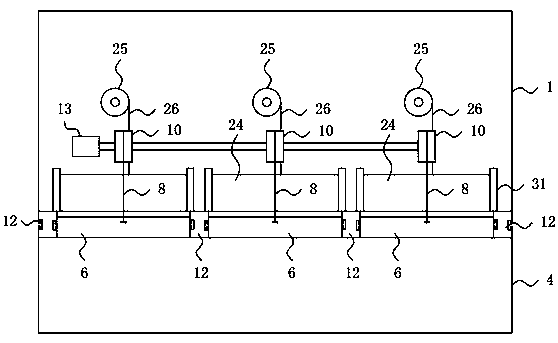

Self-reversing bagged material conveying device with high efficiency and low energy consumption

ActiveCN109051704AEnsure automatic spacingRealize automatic shuntConveyor partsEngineeringMechanical engineering

The invention discloses a self-reversing bagged material conveying device with high efficiency and low energy consumption. The self-reversing bagged material conveying device with high efficiency andlow energy consumption comprises a first conveying line, a second conveying line, a reversing mechanism and a steering mechanism, wherein a first conveying passage is formed in the first conveying line; the first conveying passage comprises multiple shunting and conveying passages formed in parallel; the second conveying line is used for conveying materials to the direction of the first conveyingdirection; a second conveying passage is formed in the second conveying line; the reversing mechanism is positioned between the second conveying line and the first conveying line to control the secondconveying passage to alternately communicate with each shunting and conveying passage in the first conveying passage; the steering mechanism comprises stopping plates and a driving unit; multiple stopping plates are arranged; each stopping plate is placed on one side of each shunting and conveying passage in sequence; a bending part is arranged at one end of each stopping plate; and the driving unit is used for driving each stopping plate to synchronously swing in the conveying direction of the first conveying passage. According to the self-reversing bagged material conveying device with highefficiency and low energy consumption, the material conveying speed can be effectively increased, and the energy consumption can be greatly reduced.

Owner:芜湖固高自动化技术有限公司

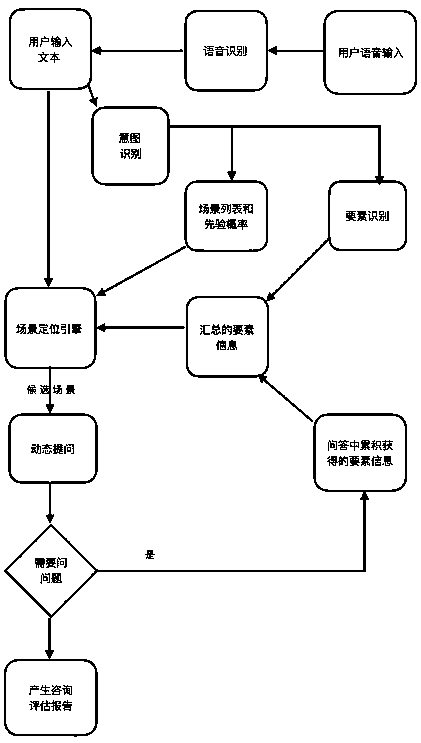

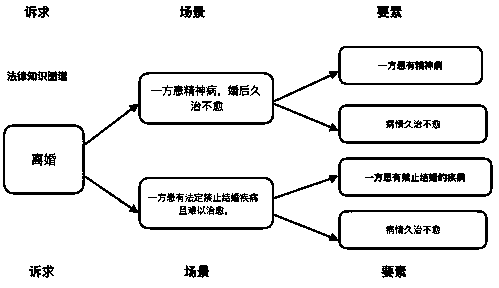

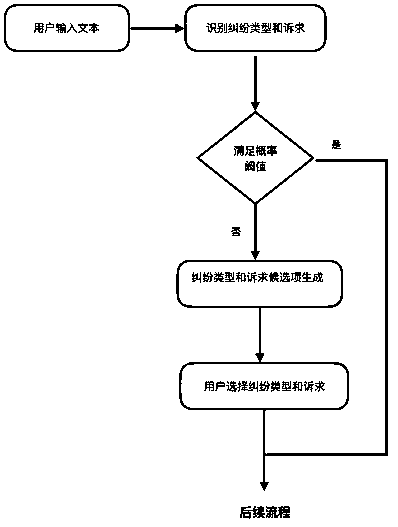

Legal consultation evaluation system based on scenarization

ActiveCN111368098AEfficient legal consultation and evaluation processSimplify Feature RelationshipsData processing applicationsSpecial data processing applicationsManual annotationSpoken language

The invention discloses a legal consultation evaluation system based on scenarization, which converts a legal consultation evaluation process into spoken language case description by combining elementcarding and recognition under a dispute type, and supports input in various forms in combination with a question and answer supplement form. Secondly, after spoken description of the user, automatically identifying a dispute type and an appeal type through machine learning and deep learning technologies in combination with manual annotation data; thirdly, in combination with a scene positioning engine, the input of the user is positioned to a specific scene under the appeal, so that a premise is provided for subsequent targeted questioning and generation of a consultation evaluation report; according to different user inputs, the positioned specific scene may be one, and may also be a few of most feasible scenes; therefore, in combination with a dynamic multi-round interactive question and answer mode, the scene of the user is determined in a least question mode through targeted questions; and generating a targeted legal consultation evaluation report according to the determined scene.

Owner:杭州实在智能科技有限公司

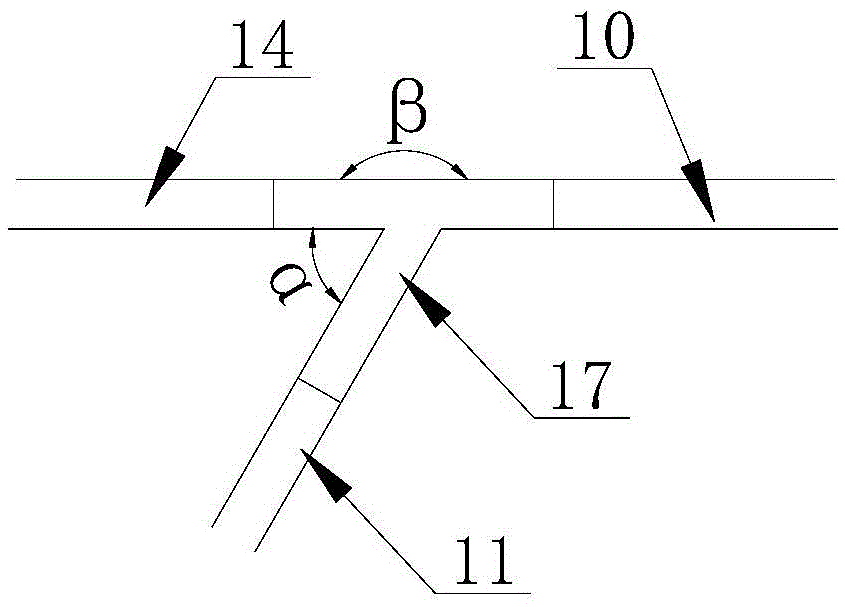

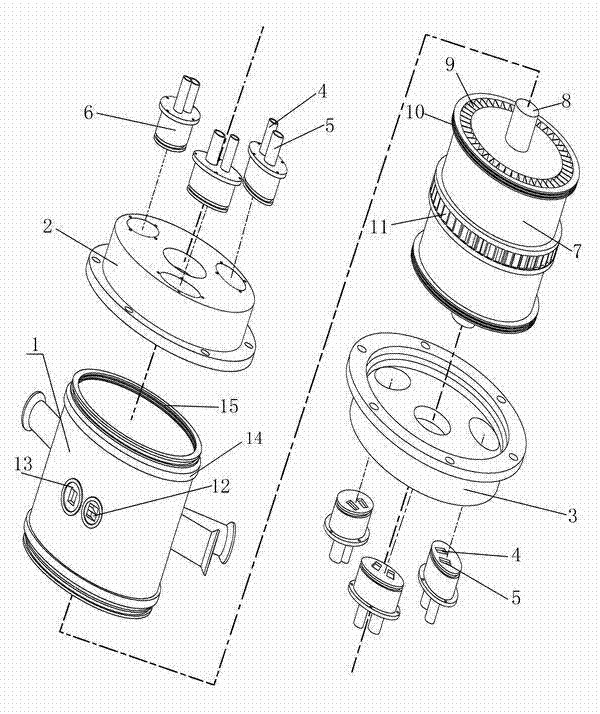

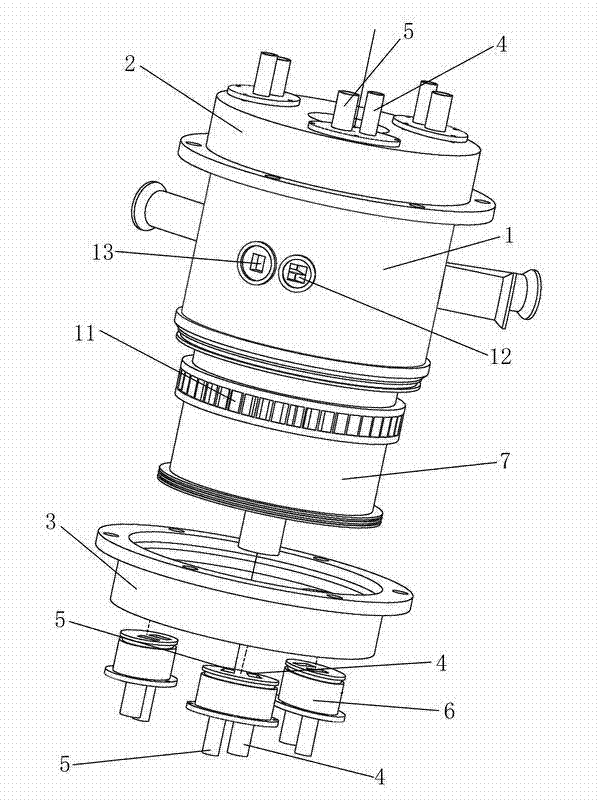

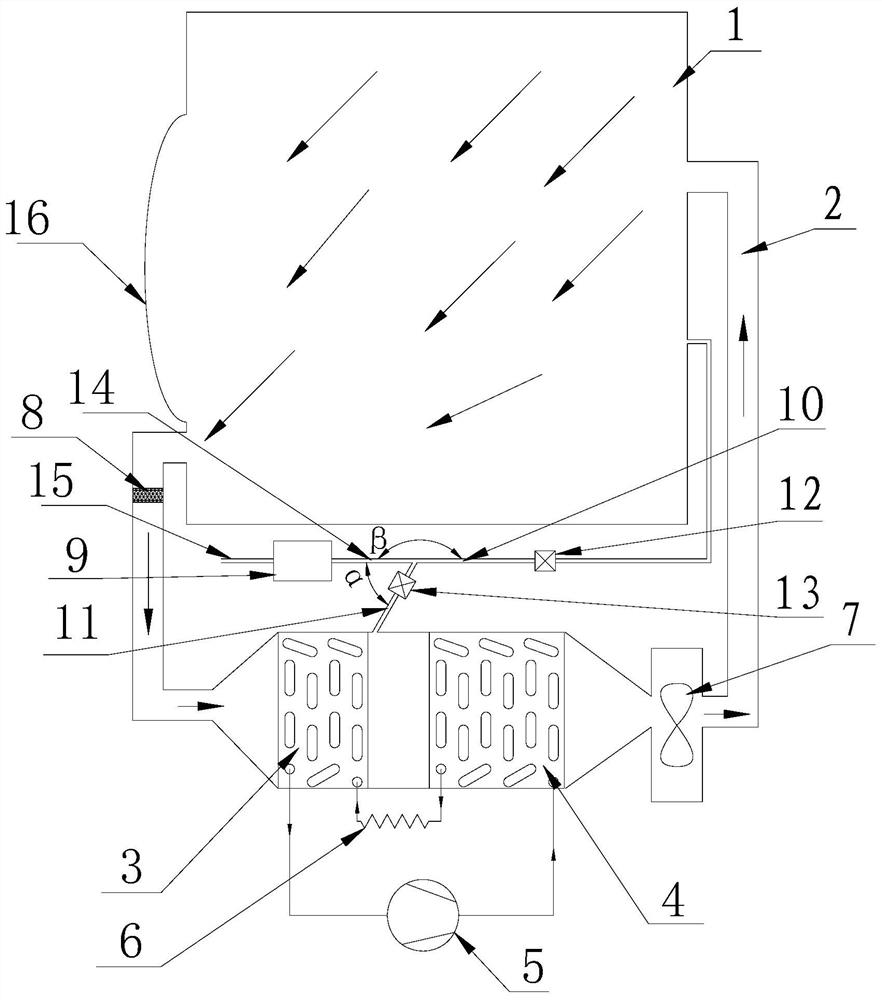

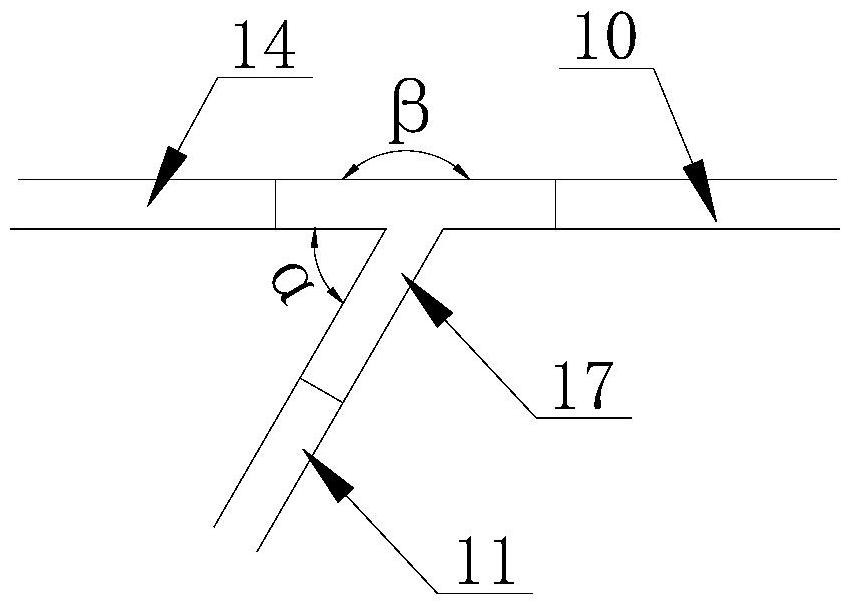

Opposite expansion wave superposition type self-driven supercharger

ActiveCN104728188ARealize automatic shuntReduce usageFluid-pressure convertersPressure.driveEngineering

The invention provides an opposite expansion wave superposition type self-driven supercharger and belongs to supercharging devices in the refrigerating and heating field. The supercharger makes use of an opposite expansion wave superposition mechanism, makes efficient use of heat energy and pressure energy of driving fluid, improves supercharging performance and has the self-driven characteristic. According to the supercharger, a main machine body is connected with an upper machine body and a lower machine body through flanges, the main machine body comprises a shell and an expansion wave superposition pipe revolving drum, a plurality of high-pressure driving liquid inlets distributed circumferentially and evenly and a plurality of low-pressure expansion fluid outlets distributed circumferentially and evenly are formed in the shell in a centering mode, expansion wave superposition pipes are circumferentially and evenly distributed on the expansion wave superposition pipe revolving drum, and skew surface transition square holes are formed in the centering position of the expansion wave superposition pipe revolving drum. The upper machine body and the lower machine body are symmetrically arranged relative to the main machine body and are each provided with a plurality of detachable nozzle combinations circumferentially and evenly distributed, and each detachable nozzle combination is composed of a supercharging fluid nozzle and a lower-pressure driven fluid nozzle. Through middle skew surface transition inlets, the revolving drum is driven to revolve, no driving machine is needed, sealing is good, and maintenance is easy. Low-temperature fluid expanded secondarily is discharged through the low-pressure expansion fluid outlets, and a temperature drop is large. Supercharging airflow is discharged through the supercharging fluid nozzles at two ends, and the supercharging effect is good.

Owner:DALIAN UNIV OF TECH

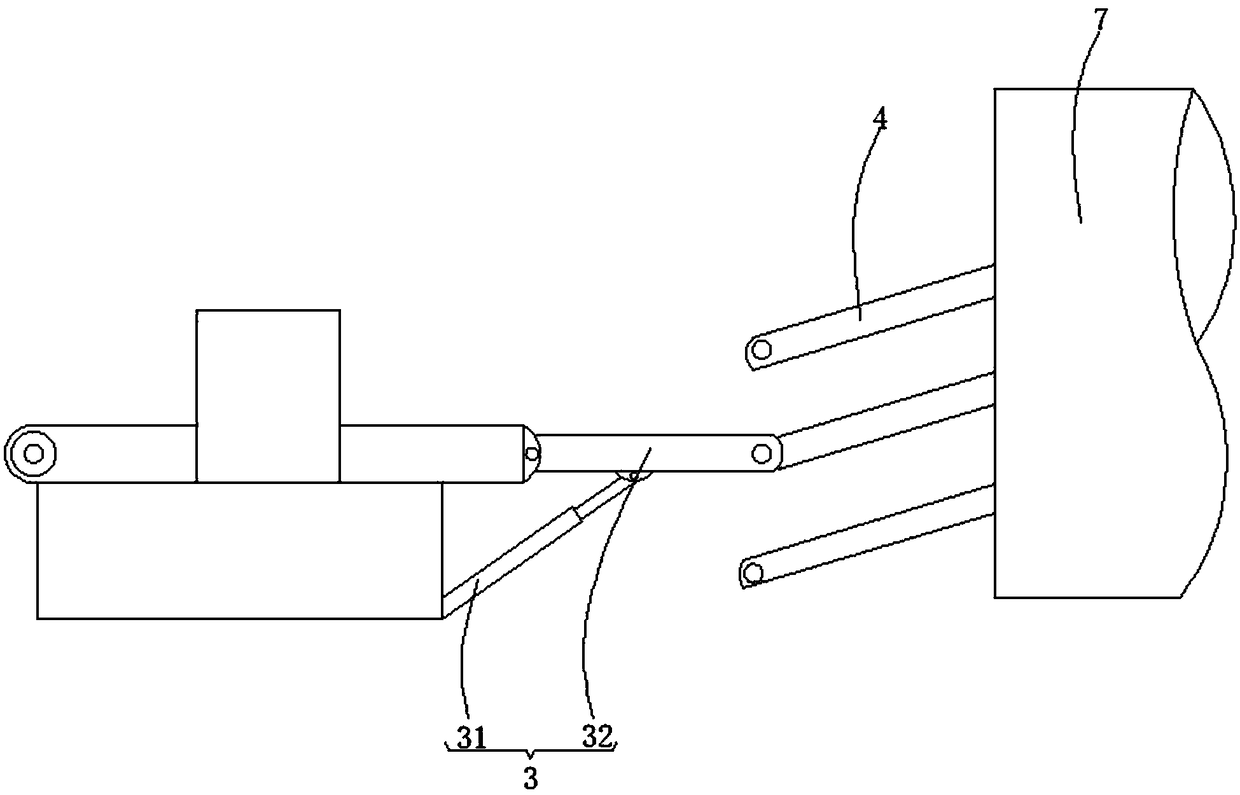

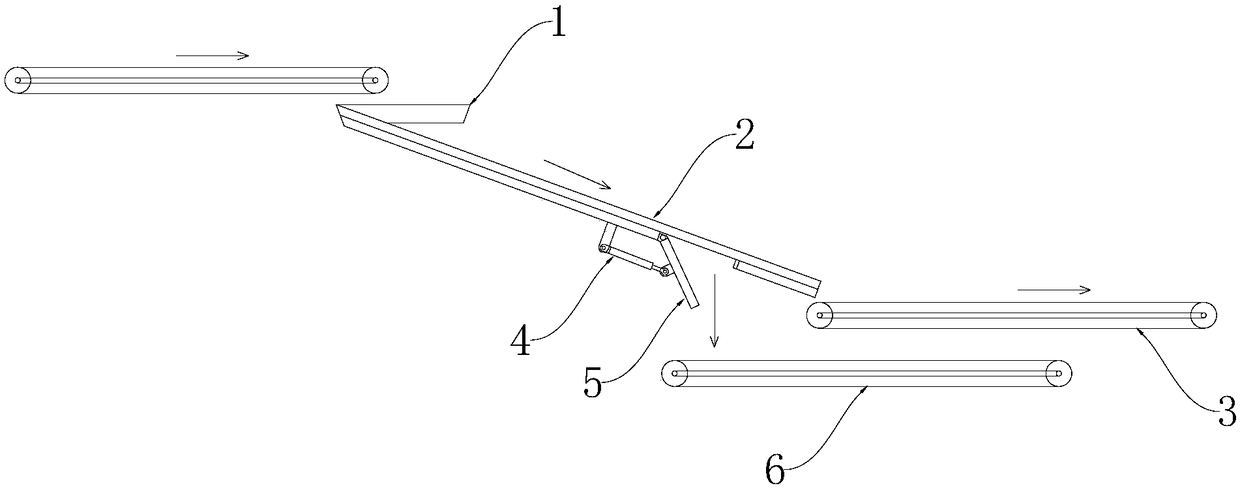

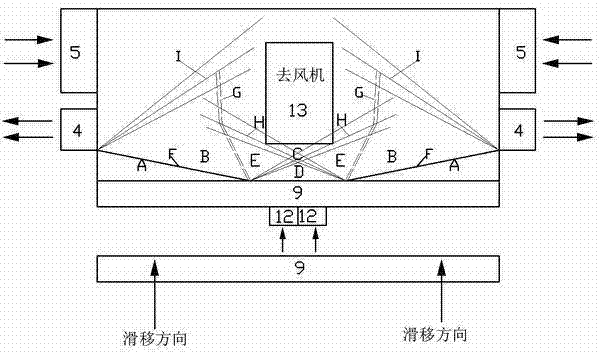

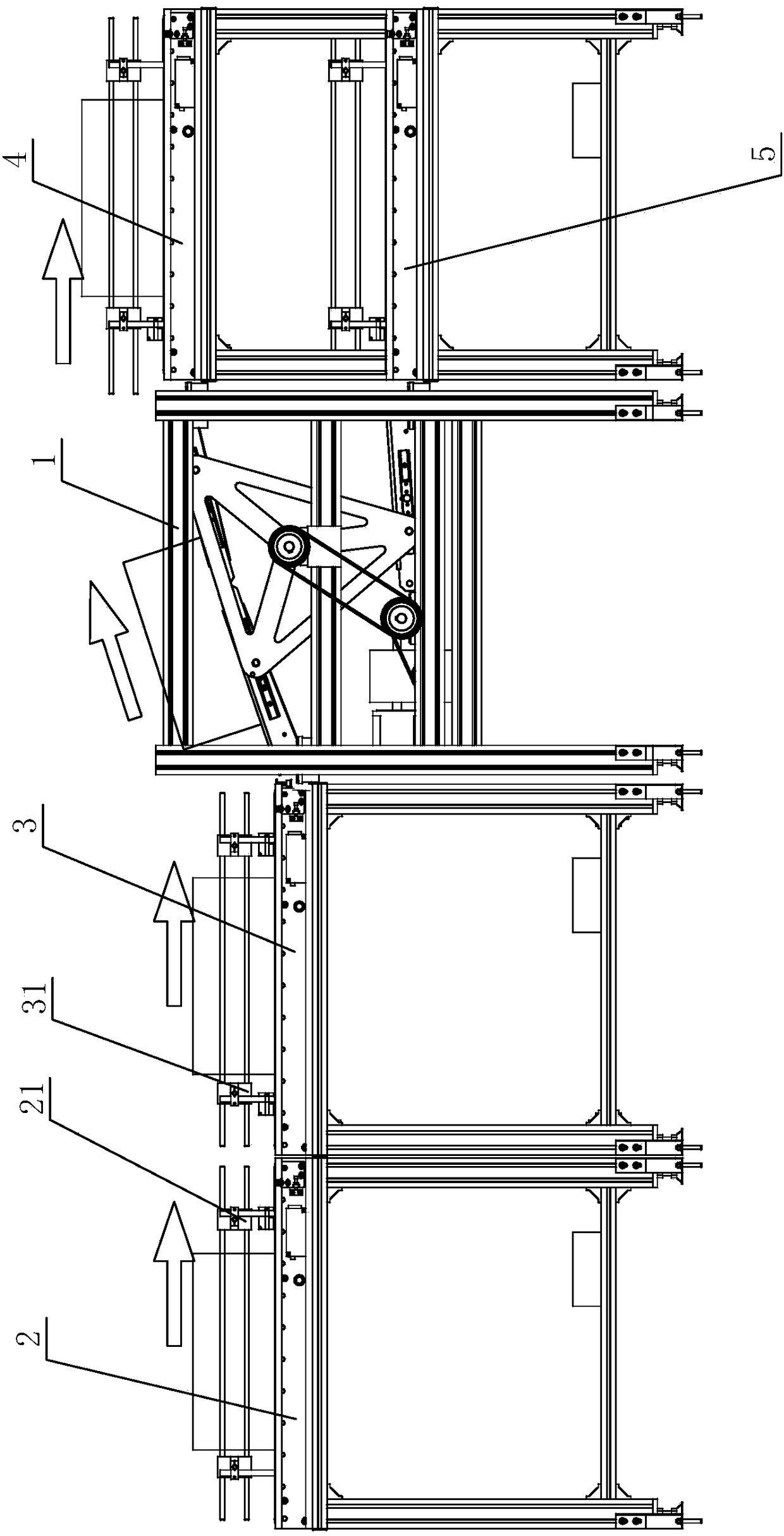

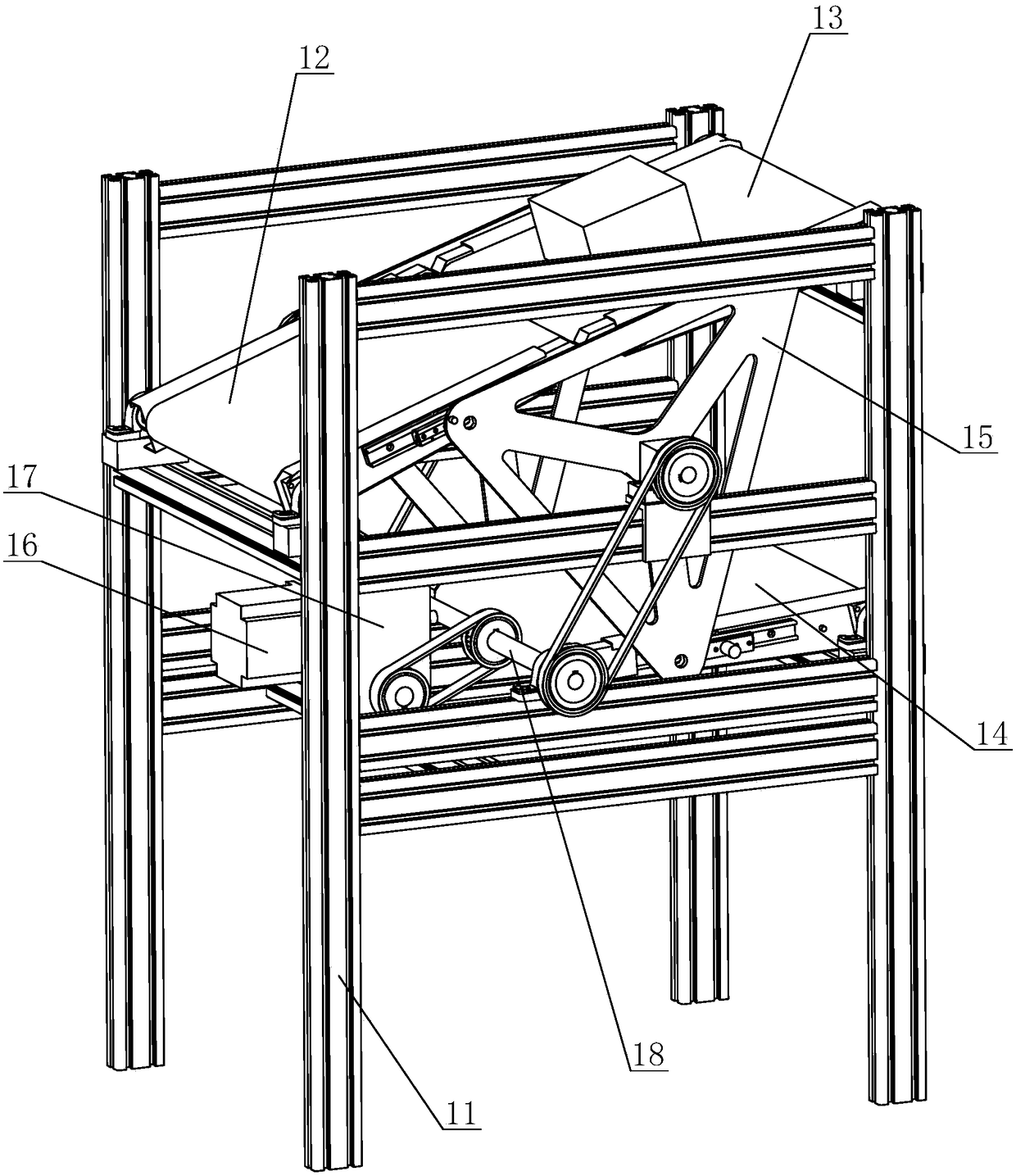

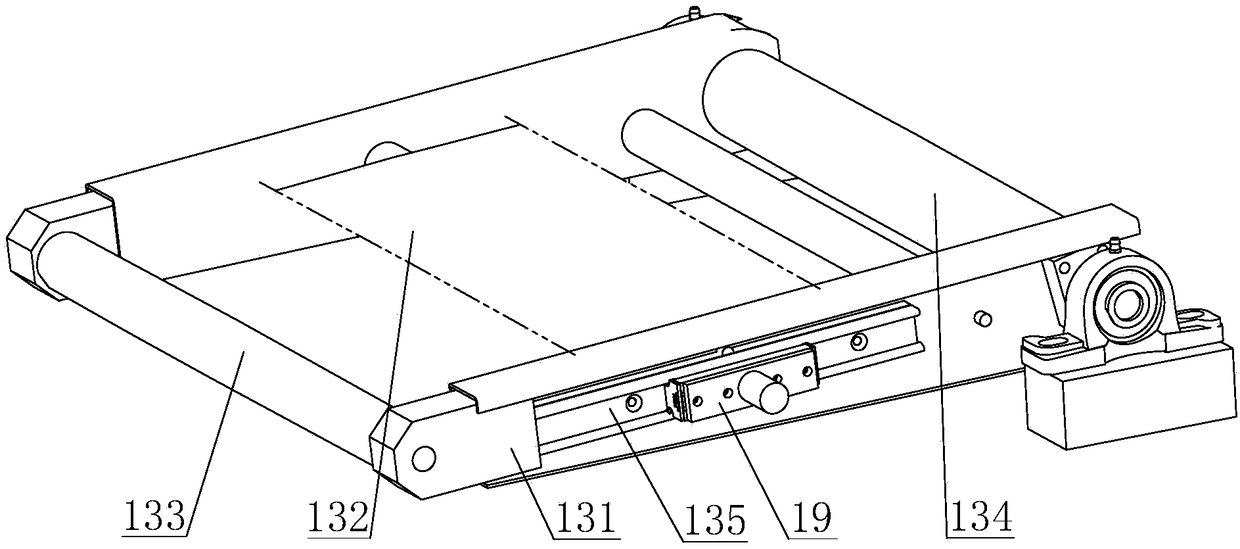

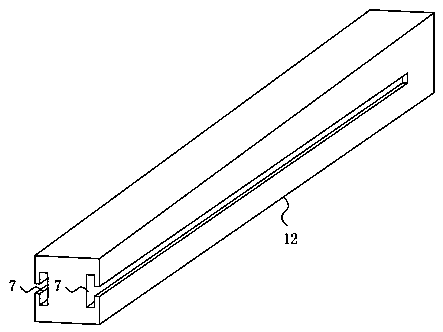

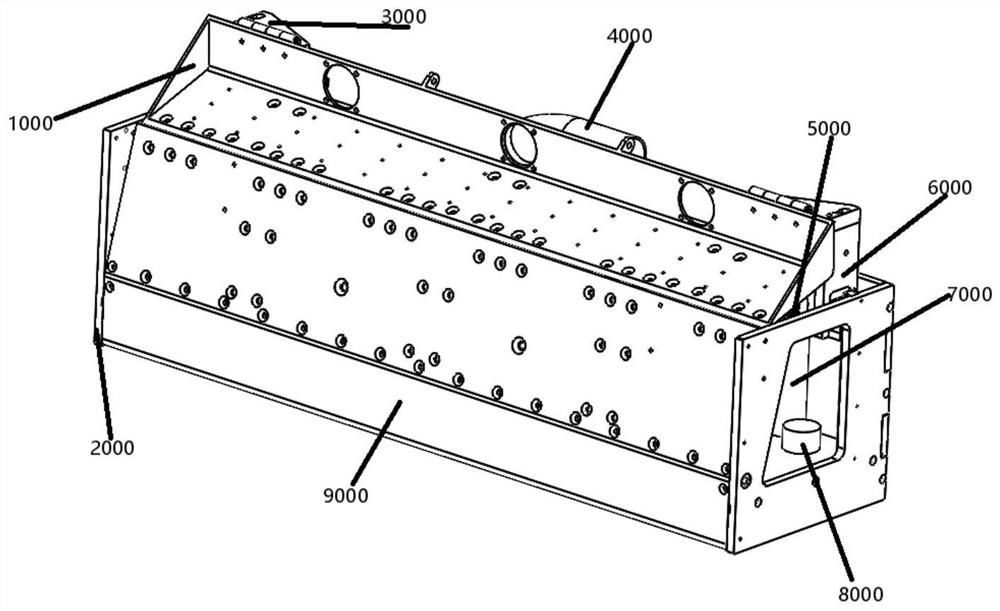

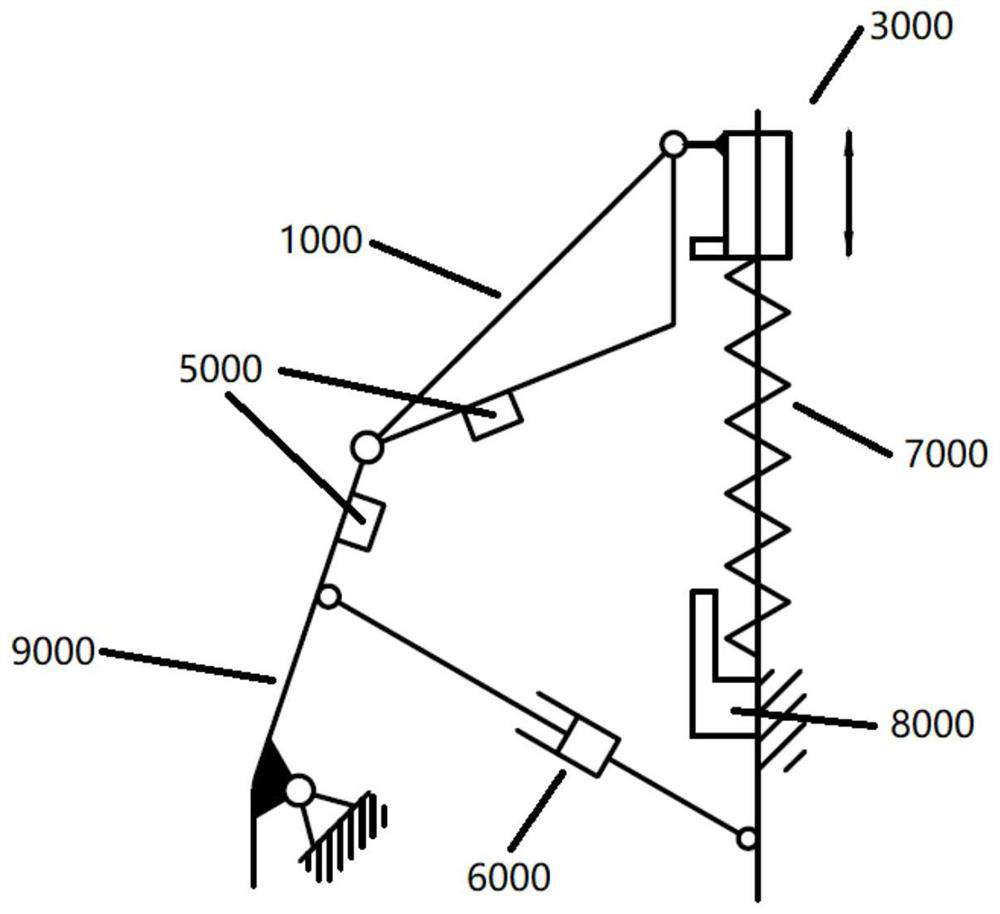

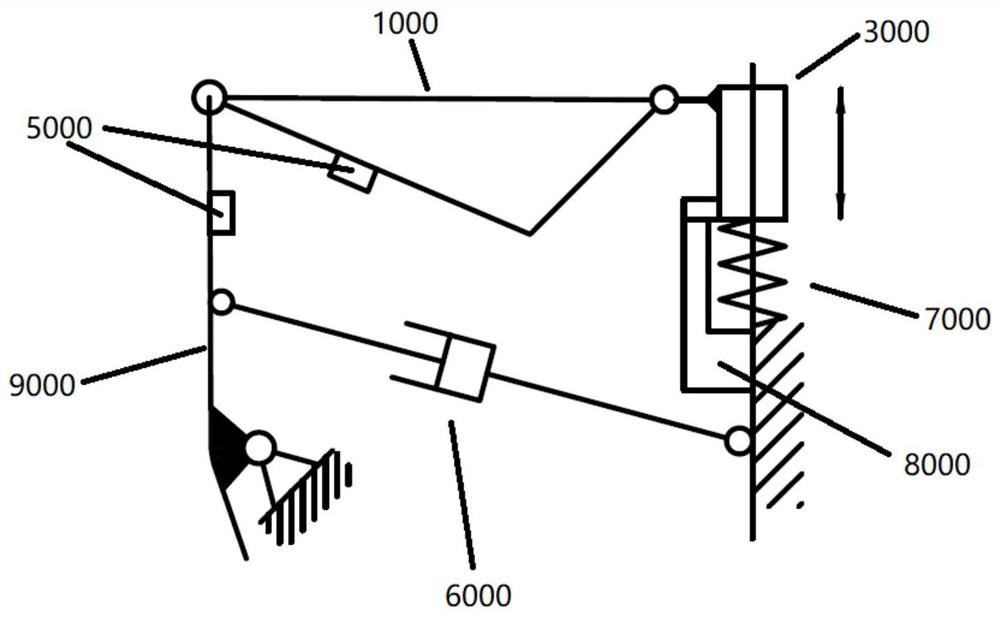

Cargo flow dividing conveying line

PendingCN108394695ARealize automatic shuntImprove shunt efficiencyControl devices for conveyorsSupporting framesEngineeringAutomation

The invention discloses a cargo flow dividing conveying line. The cargo flow dividing conveying line comprises a controller, a front section conveying line, a rear section conveying line and a swinging arm conveying device, wherein, the front section conveying line, the rear section conveying line and the swinging arm conveying device are controlled by the controller, and a code reader is mountedon the front section conveying line and electrically connected with the controller; the rear section conveying line comprises an upper layer conveying line on the upper portion and a lower layer conveying line on the lower portion, and the swinging arm conveying device is located between the front section conveying line and the rear section conveying line and comprises a rack, a first conveying line, a second conveying line and a third conveying line; and the front end of the first conveying line is hinged to the front end of the rack, the rear end of the second conveying line is hinged to theupper portion of the rear end of the rack, the rear end of the third conveying line is hinged to the lower portion of the rear end of the rack, and the rack is rotatably connected with a linkage bracket and is provided with a driving device used for driving the linkage bracket to rotate. The cargo flow dividing conveying line has the characteristics of simple structure, small size, low manufacturing cost and high automation degree.

Owner:WUXI GALAXIS AUTOMOTION MANAGEMENT GMBH

Lung rehabilitation training equipment for patient with chronic respiratory disease

InactiveCN114534199AEasy to retractRetractableGymnastic exercisingDispersed particle separationActivated carbonPhysical medicine and rehabilitation

The invention belongs to the technical field of rehabilitation training equipment, and particularly relates to lung rehabilitation training equipment for chronic respiratory disease patients, which comprises a base, a lifting mechanism is arranged on the base, the output end of the lifting mechanism is fixedly connected with a box body, a purification cavity and a storage cavity are arranged in the box body, and an activated carbon purification layer is fixedly arranged in the purification cavity. Two guide pipes are rotationally connected into the storage cavity, and an air guide roller is fixedly connected between the two guide pipes. When a patient carries out respiratory training, airflow generated in the inspiration and expiration processes can be shunted, exhaled waste gas is prevented from being inhaled by the patient again, the tedious process of intermittently picking off a mask in the training process of the patient is avoided, meanwhile, air can be circularly purified and utilized, and the training efficiency is improved. In addition, the using length of the air pipe can be adjusted and controlled according to needs, and the air pipe can be orderly stored in the later period.

Owner:三门峡市中心医院

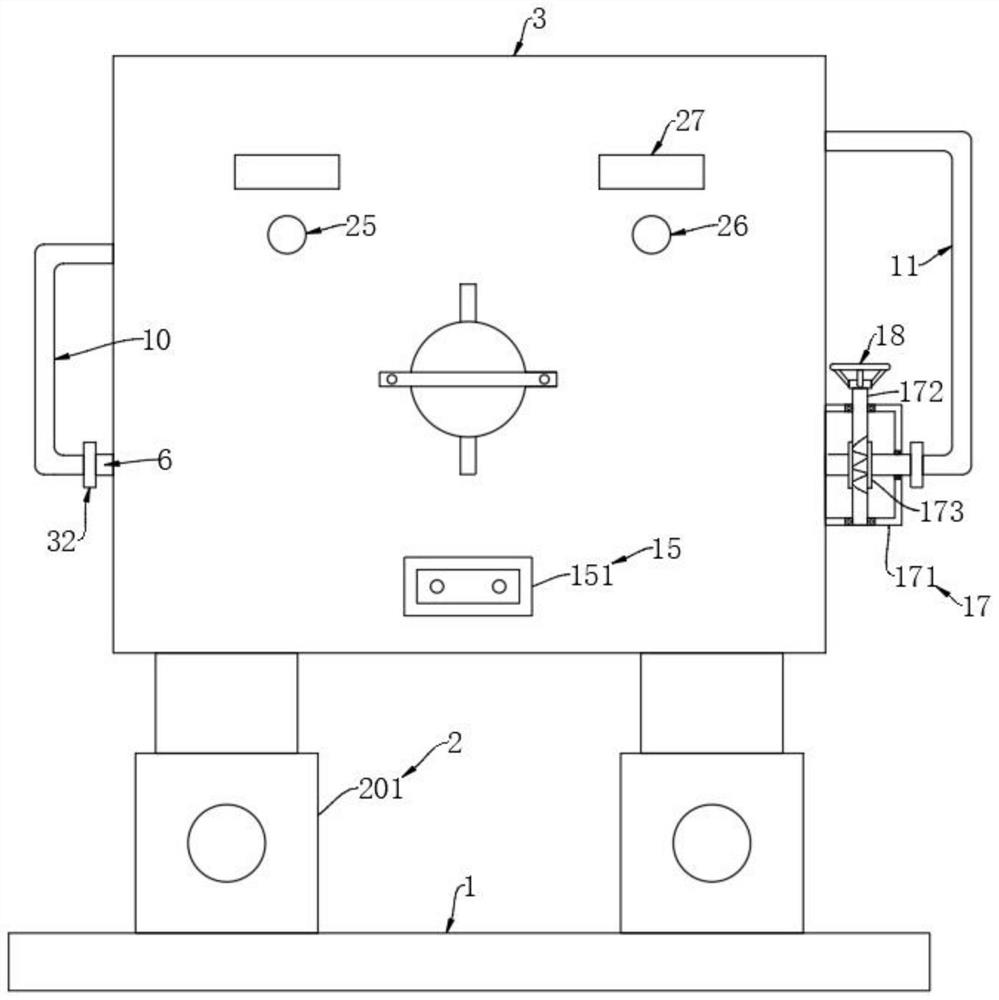

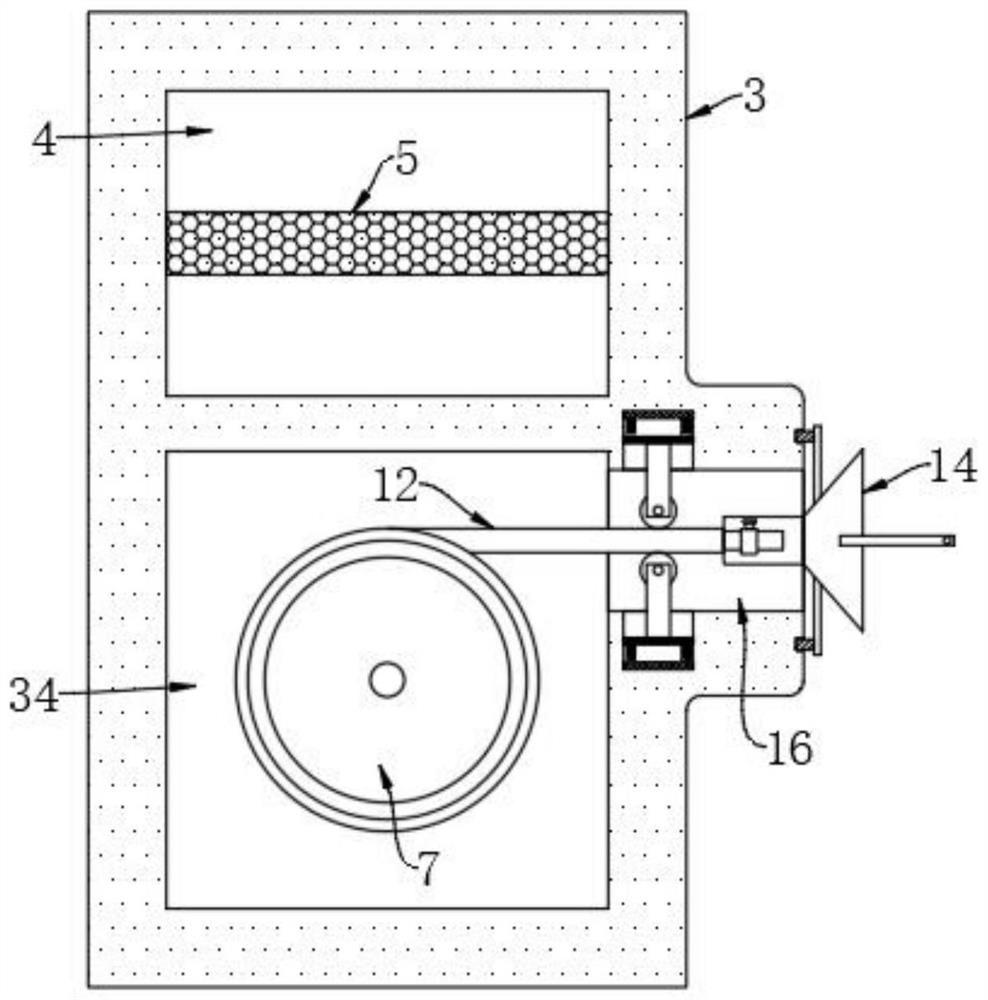

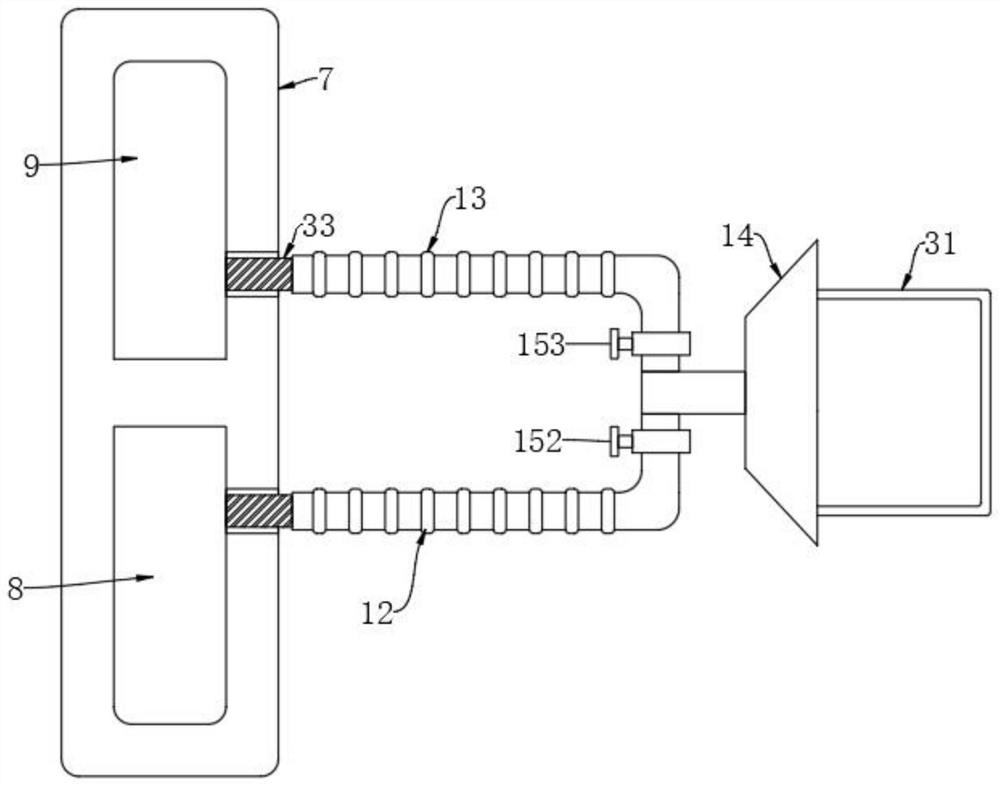

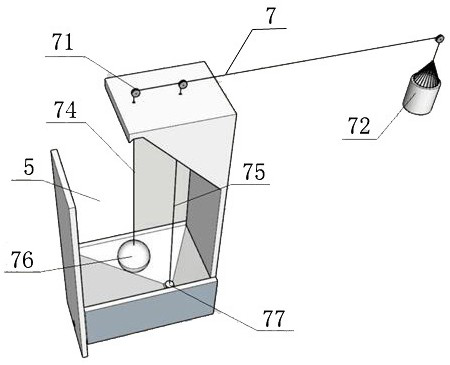

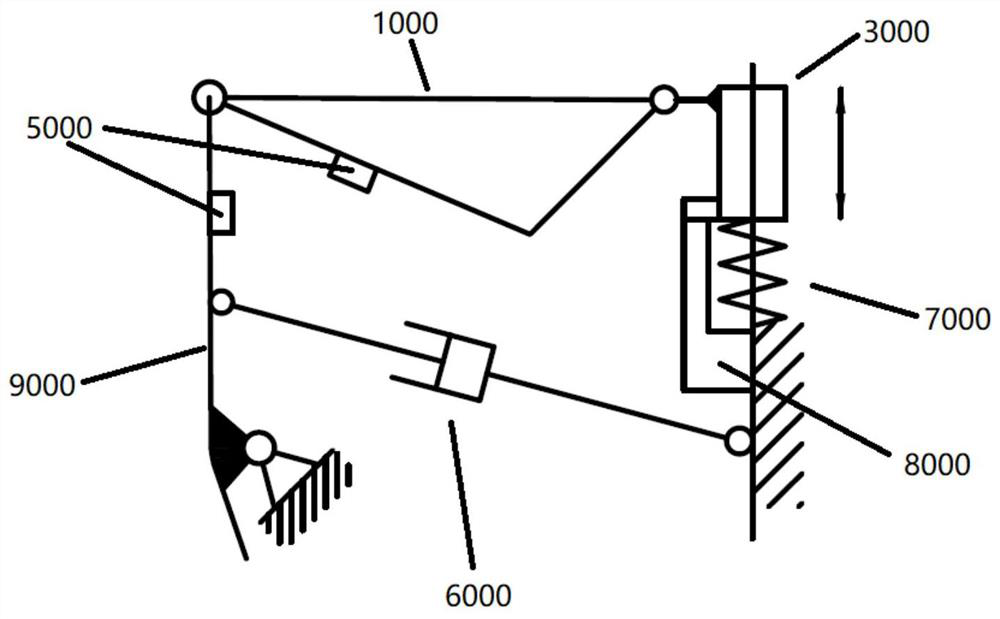

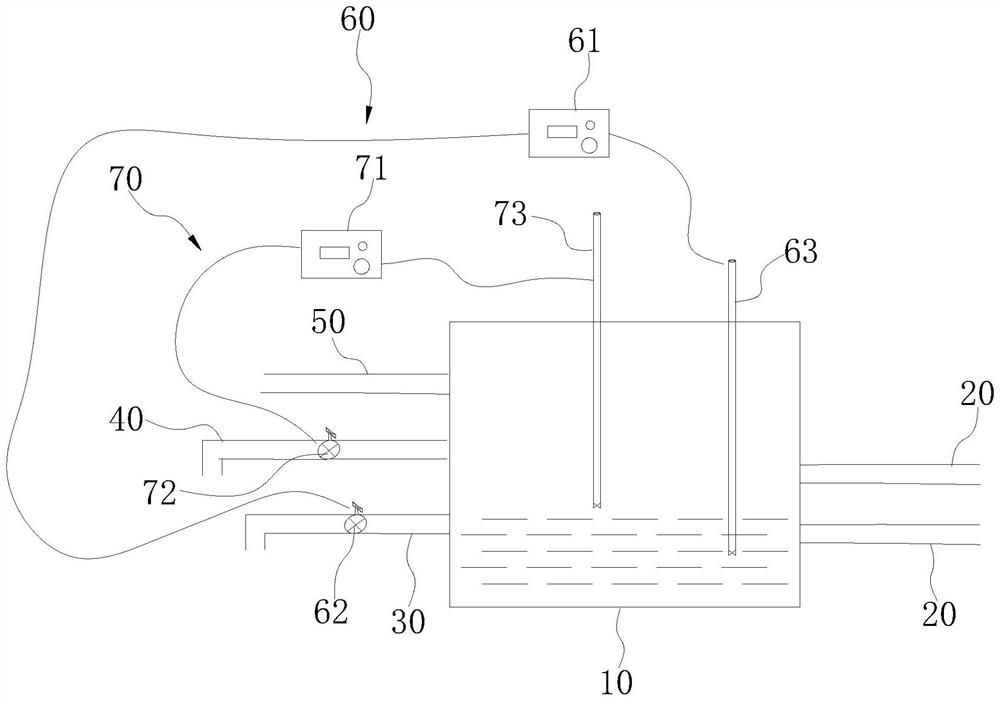

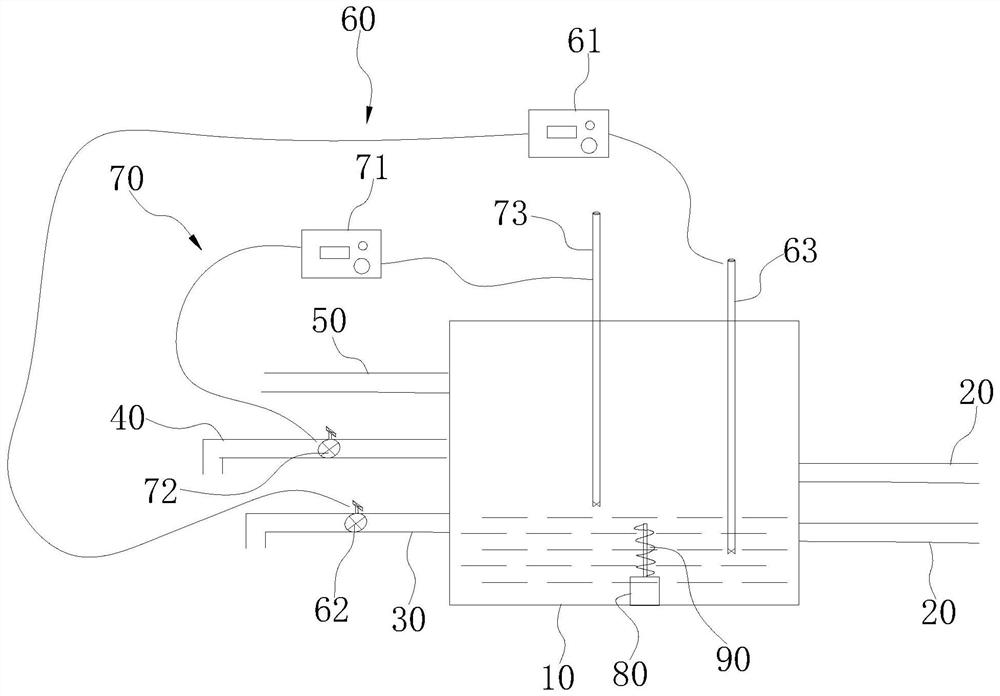

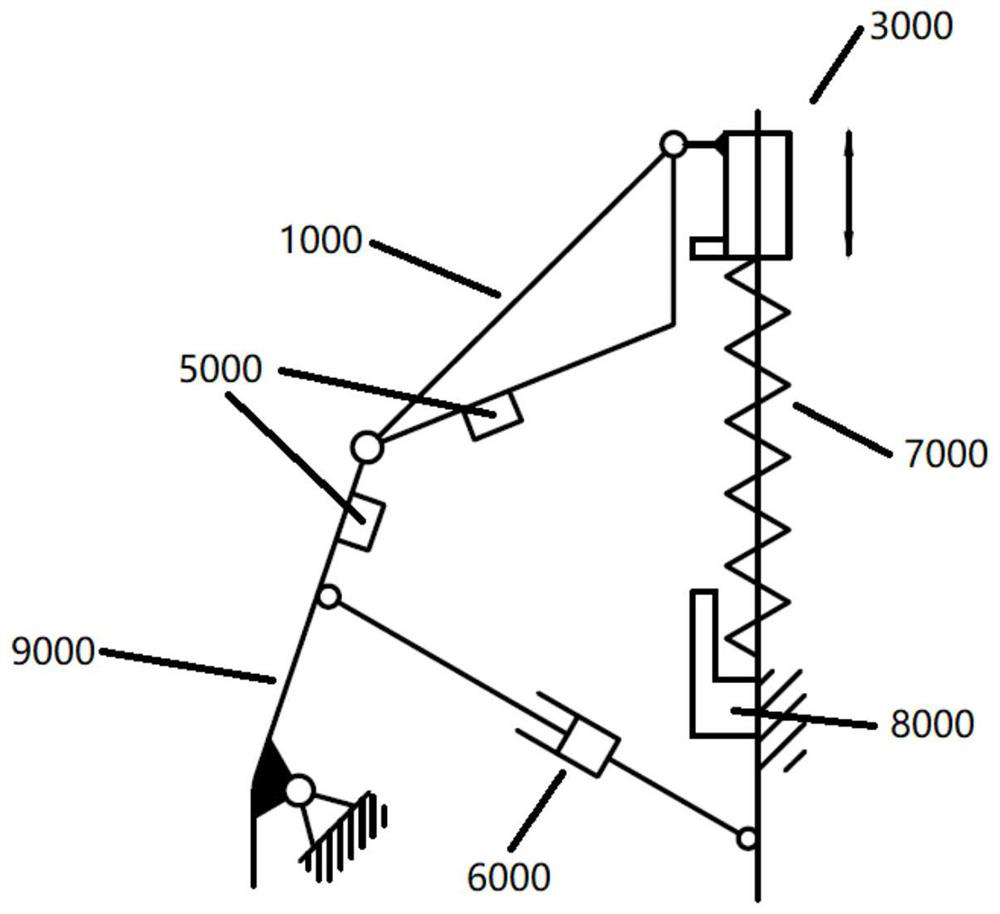

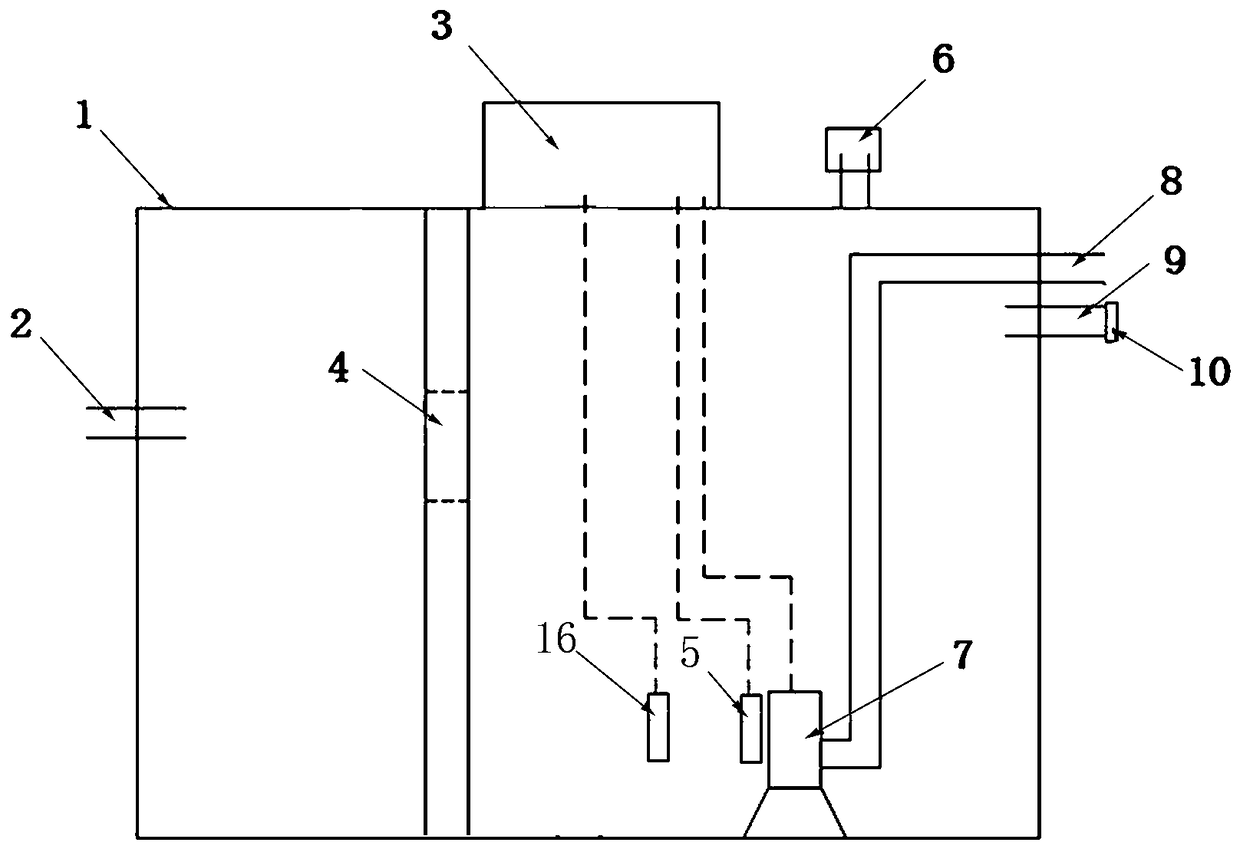

Automatic initial rainwater diversion device

PendingCN113073719ARealize automatic shuntReduce pollutionFatty/oily/floating substances removal devicesSewerage structuresEnvironmental engineeringStormwater

The invention discloses an automatic initial rainwater diversion device, and belongs to the technical field of rainwater separation. The automatic initial rainwater diversion device comprises a rainwater diversion pool, an initial rainwater storage tank, a switching device and a time delay device, wherein the initial rainwater storage tank is located under the rainwater diversion pool; an initial rainwater channel is located in the left side of the initial rainwater storage tank; a middle-later rainwater inlet is formed in the right side wall of the rainwater diversion pool, and a middle-later rainwater channel is vertically and downwards arranged in the right side of the initial rainwater storage tank; the switching device is arranged on a partition wall between the initial rainwater channel and the initial rainwater storage tank; and the time delay device is installed between the middle-later rainwater channel and the initial rainwater storage tank. The automatic initial rainwater diversion device has the technical effects that automatic diversion of initial rainwater and middle and later rainwater is realized, so that the initial rainwater is collected and treated, and the middle and later rainwater is collected and reused; and after runoff is finished, the device can automatically recover to an initial state, manual control is not needed, and energy consumption is avoided.

Owner:CHONGQING UNIV

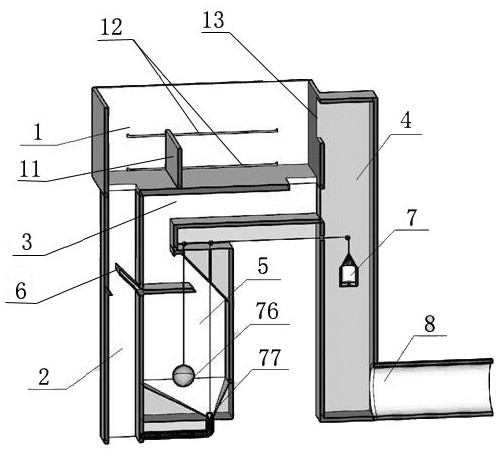

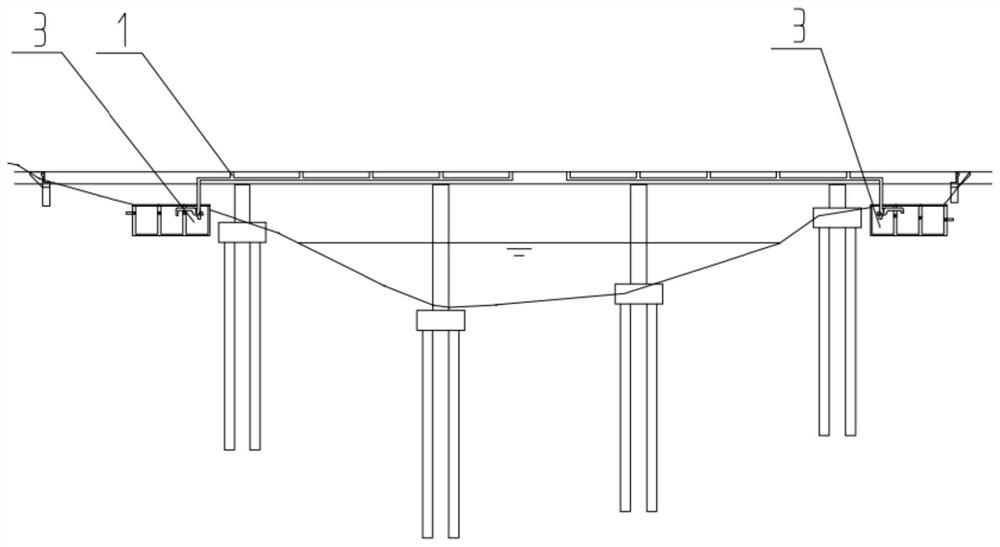

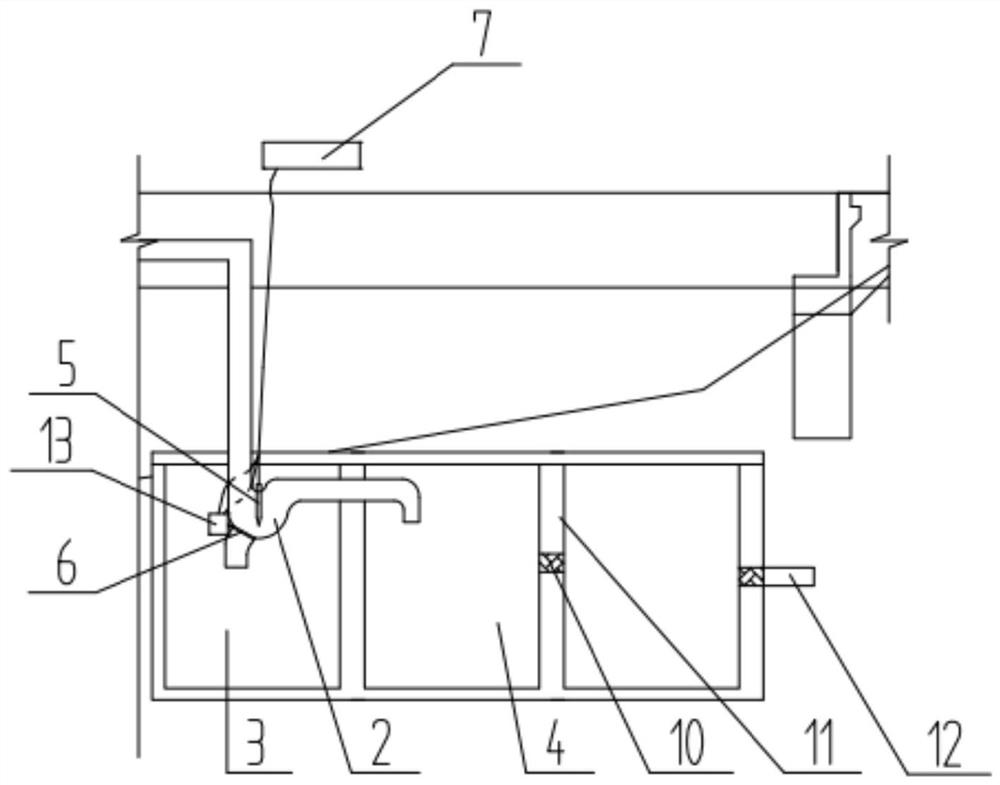

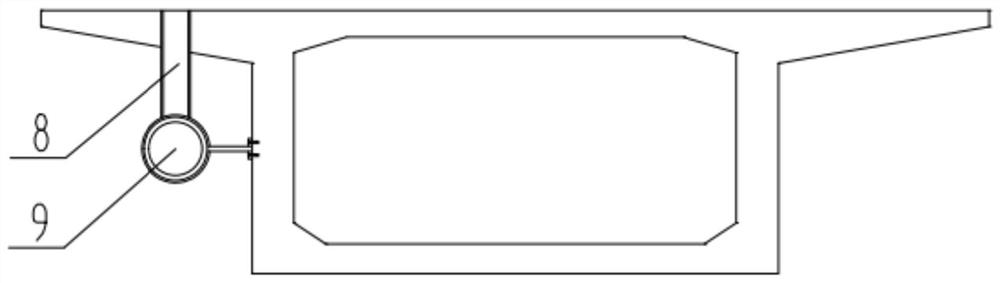

Pig house

PendingCN110934077ARealize automatic shuntReduce energy consumptionAnimal housingEnvironmental engineeringMechanical engineering

The invention provides a pig house, and aims to solve the technical problem that a conventional pig house cannot perform automatic shunting on excrement and urine. The technical scheme of the invention lies in that the pig house comprises a house main body, wherein the house main body consists of excrement leakage plates, enclosing walls and a house roof; a baseplate is arranged below the excrement leakage plates; the upper surface of the baseplate slopes downwards from left to right; the slope of the baseplate is 0.5%-3%; gaps are formed between the baseplate and the excrement leakage plates;a dry excrement pond is arranged on the left side of the house main body; a waste liquid pond is arranged on the right side of the house main body; excrement scraping plates which extend in the frontand rear direction and a guide rail which is adapted with the excrement scraping plates and extends in the left-and-right direction are arranged on the upper surface of the baseplate; the left end ofthe guide rail extends above the dry excrement pone, and the right end of the guide rail extends above the waste liquid pond; a traction rope and a resetting rope are connected to the excrement scraping plates; the traction rope extends towards the dry excrement pond, and is twisted to a traction capstan above the dry excrement pone; and the resetting rope extends towards the waste liquid pond, and is twisted to a resetting capstan above the waste liquid pond.

Owner:巨星农牧有限公司

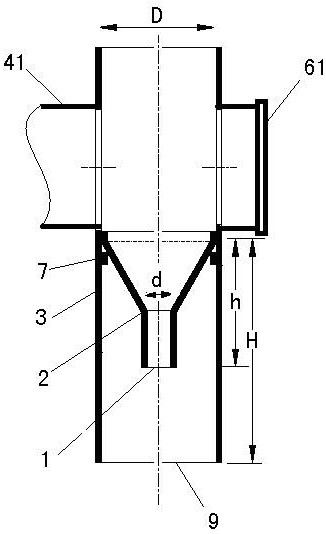

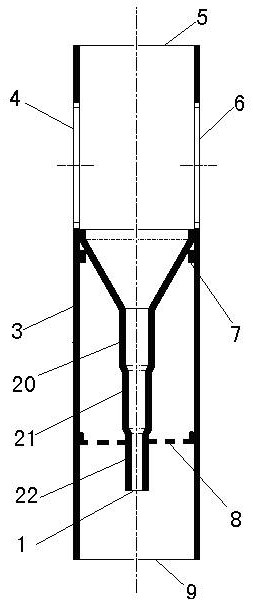

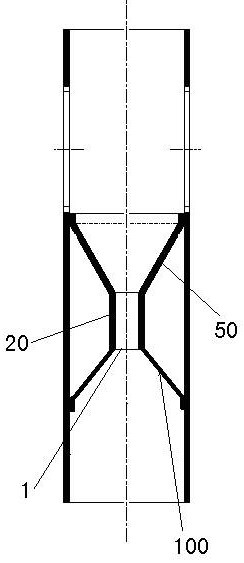

Rain and sewage diverter for building vertical pipe

The invention discloses a rain and sewage diverter for a building vertical pipe, which comprises an outer pipe and a beam pipe which is connected with the inner wall of the outer pipe and is arranged in the outer pipe, the pipe wall of the outer pipe above the beam pipe is provided with a rainwater overflow port and an access hole, the beam pipe is funnel-shaped and is provided with a horn mouth and a straight drainage pipe section which is located at the lower end of the beam pipe and has the pipe diameter smaller than that of the outer pipe. When the diverter is used, the upper end is directly connected to a downpipe of a building, the lower end is connected to a municipal sewage pipe network, and the overflow port is connected to a municipal rainwater pipe network; the diverter is low in production cost and convenient to install and use, the situation that sewage pollutes a rainwater pipe network and the building environment can be effectively avoided, and great economic and social benefits can be brought after application and popularization.

Owner:南通润远工程设计有限公司

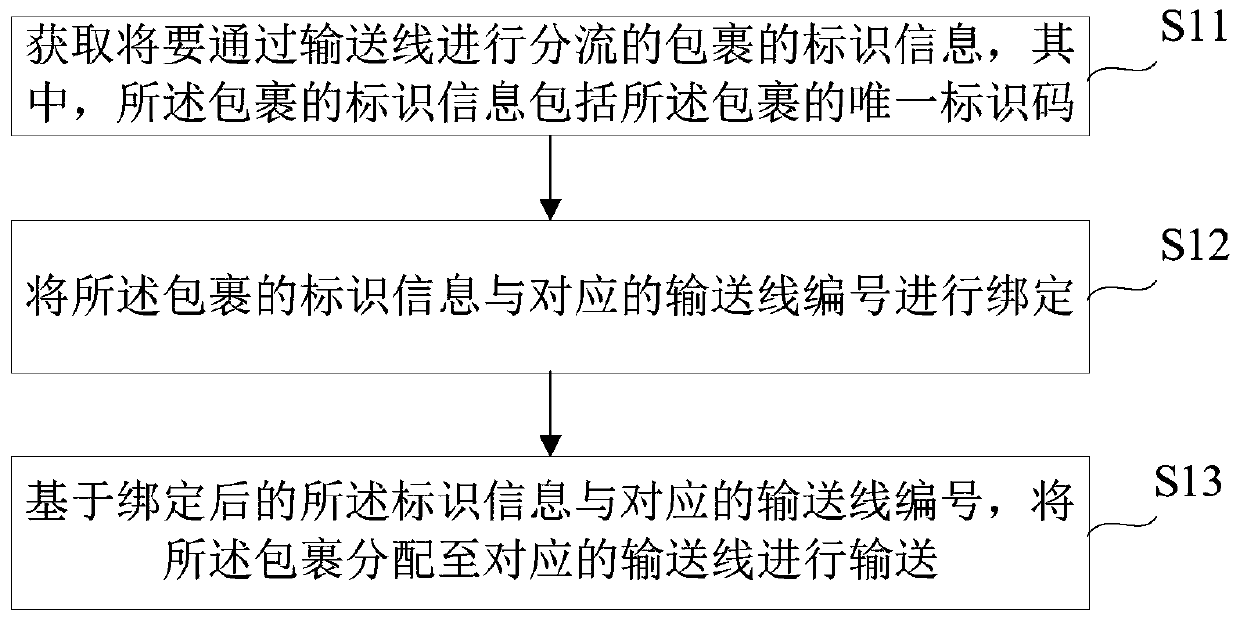

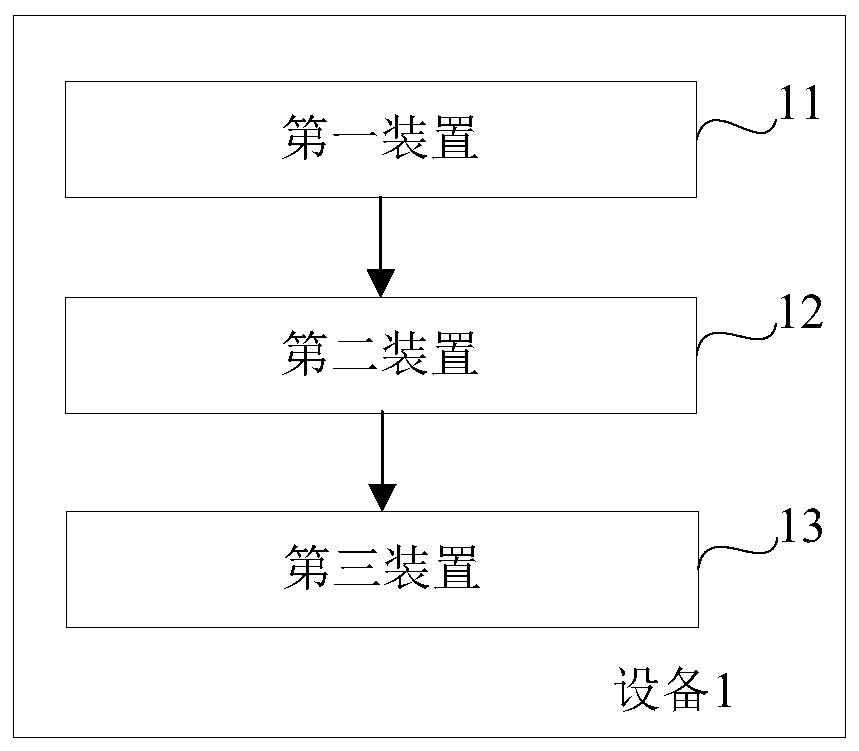

A method and equipment for diverting packages through conveyor line

PendingCN110880028ASave human effortImprove work efficiencyCo-operative working arrangementsLogisticsProcess engineeringSystems engineering

Owner:SHANGHAI WANWUXINSHENG ENVIRONMENTAL PROTECTION TECH GRP CO LTD

Plastering head

The invention provides a plastering head. The plastering head comprises a frame, a forming plate arranged on the frame and used for achieving wall adhering of a plastering medium and a hopper; an acute angle is formed between the forming plate and a vertical direction, a wedge-shaped space is formed between the forming plate and the wall surface, and the plastering head is in a plastering posture;the hopper is hinged to the upper end of the forming plate and used for flattening and storing the plastering medium, and the hopper is inclined relative to a horizontal direction, so that the plastering medium flows into the wedge-shaped space from the hopper under the action of gravity; the hopper can be overturned and pressed downwards to drive the forming plate to be overturned and pressed forwards, and when the forming plate is overturned and pressed to be in a vertical state, the plastering head is changed into a scraping posture from a plastering posture; and a linear motion part can accurately limit the overturning and pressing action in the overturning and pressing process, and when the linear motion part moves downwards to a designated position, the position of the linear motionpart can be kept fixed through a limiting part. According to the plastering head, manual intervention is reduced, plastering quality control is good, the mortar utilization rate is high, and the procedures of feeding, flattening, wall mounting, scraping and the like of plastering operation can be carried out in a small space.

Owner:上海蔚建科技有限公司

Clothes dryer with steam function and steam control method

ActiveCN106592179BReduce the amount requiredAvoid squirtingTextiles and paperLaundry driersThermodynamicsWater vapor

The invention relates to a clothes dryer with a steam function. The clothes dryer is provided with a steam generator. An air outlet of the steam generator is communicated with an outer barrel and a drying wind path through pipes, so steam flows to the outer barrel and / or the drying wind path in a controllable manner. The invention also relates to a steam control method of the clothes dryer. In a normal steam treating process of the clothes dryer on clothes, at least most water vapor generated by the steam generator flows into the outer barrel. When a door body on a clothes putting opening of the clothes dryer is open, at least most water vapor generated by the steam generator flows into the drying wind path. Through the above device and method, steam generated by the steam generator flows to the outer barrel and / or the drying wind path in a controllable manner, preventing occurrence that large amount of steam sprays from an opening formed by opening of the door body and waste heat hurts users caused by steam flowing into the outer barrel after a user opens the door body. The clothes dryer is simple in structure and substantial in effect, and is suitable for popularization and application.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Fuse detecting system

InactiveCN105289996AImprove work efficiencyReduce defective productsSortingSquare ShapeElectrical and Electronics engineering

The invention relates to a fuse detecting system which comprises a feed device, a push device arranged at the rear end of the feed device, a homocentric squares-shaped push device opposite to the push device, a detecting table between the push device and the homocentric squares-shaped push device, a first detecting device for detecting whether a fuse exists on the detecting table or not and detecting whether the fuse is qualified or not, a first current dividing device located at the rear end of the detecting table, a second current dividing device located at the rear end of the first current dividing device, and a second detecting device for detecting whether a fuse on the second current dividing device is qualified or not. The second current dividing device comprises a current dividing base, a current dividing pipe arranged on the current dividing base and capable of moving on the current dividing base, a horizontally-moving driving piece for driving the current dividing pipe to move, and a to-be-detected piece located on the current dividing pipe. A first current dividing hole and a second current dividing hole penetrate through the current dividing base. A to-be-detected hole penetrates through the to-be-detected piece. The first current dividing hole, the second current dividing hole, the to-be-detected hole and the current dividing pipe are all in parallel.

Owner:SUZHOU ANTAUR AUTOMATION EQUIP

PH-based rainwater and sewage pipe network intelligent diversion device

InactiveCN109208734ARealize secondary collectionReduce the riverControlling ratio of multiple fluid flowsSewage drainingLevel sensorSewage

The invention discloses a pH-based rain and sewage pipe network intelligent diversion device, comprising a control box, a sewage pump, a liquid level gauge, a pH value sensor, an intelligent control system, wherein the intelligent control system controls the start and stop of the sewage pump, and the sewage pump discharges the sewage to a designated sewage well; the pH-based rain and sewage pipe network intelligent diversion device comprises a control box, a sewage pump, a liquid level gauge, a pH value sensor and an intelligent control system. At least two liquid level data are preset in thatintelligent control system, which are marked as a start liquid level and a shutdown liquid level, and the shutdown liquid level is high than the top elevation of the sewage pump; When the liquid level measured by the liquid level gauge is higher than the starting liquid level and the pH value measured by the sensor is greater than 9 or less than 6, the sewage pump is started to work. Turn off thesewage pump when the pH value measured by the sensor is between 6 and 9 or when the level measured by the level gauge is lower than the shut-off level. The invention can realize the secondary collection of sewage. The device can collect initial rainwater, reduce pollutants into the river; Intelligent control system, which can realize automatic rainwater and sewage distribution; Flood discharge and drainage will not be affected.

Owner:宁波点溪环保科技有限公司

Multi-waste liquid diversion method and electroplating production system

ActiveCN110387573BRealize automatic shuntReduce labor intensityCellsControlling ratio of multiple fluid flowsLiquid storage tankProcess engineering

The invention relates to a multi-waste-liquid splitting device and an electroplating production system. The multi-waste-liquid splitting device comprises a liquid storage tank, a first waste liquid detection assembly and a second waste liquid detection assembly, wherein one end of the liquid storage tank is in communication with a liquid inlet pipe, and the other end of the liquid storage tank isin communication with an acid liquid drainage pipe, a maintenance liquid drainage pipe and a cleaning liquid drainage pipe; the first waste liquid detection assembly comprises a first controller, a first electric control valve and a first detection sensor, the first electric control valve is in communication with the acid liquid drainage pipe and the first detection sensor is arranged inside the liquid storage tank; and the second waste liquid detection assembly comprises a second controller, a second electric control valve and a second detection sensor, the second electric control valve is incommunication with the maintenance liquid drainage pipe and the second detection sensor is arranged inside the liquid storage tank, wherein each of the first detection sensor and the second detectionsensor is provided with a PH value detection module and an ORP detection module. According to the multi-waste-liquid splitting device, automatic splitting of waste liquid with different properties can be automatically realized according to the measured PH value and the measured ORP value, the splitting precision and the splitting efficiency are high, the whole process does not need manual participation, and the labor intensity of workers is reduced.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +1

a plaster head

The invention provides a plastering head, which includes a frame, and a forming plate arranged on the frame for bonding the upper wall of the plastering medium; the forming plate is arranged at an acute angle to the vertical direction, and a wedge shape is formed between the forming plate and the wall surface space, the plastering head is in the posture of putting up the plaster; the hopper for flattening and storing the plastering medium is hinged with the upper end of the forming plate; the hopper is set on an inclined plane with the horizontal direction, so that the plastering medium flows into the wedge from the hopper under the action of gravity In the space; and the hopper can be turned downwards to drive the forming board to turn forward. When the forming board is turned upright, the plastering head changes from the dusting posture to the scraping posture; the linear moving parts limit the turning process The overturning action can be accurately realized, and when the linear moving part moves down to the specified position, its position can be kept fixed by the limiting part. The invention reduces manual intervention, has good plastering quality control, and has a high utilization rate of mortar; and realizes the processes of material supply, flattening, wall mounting, and scraping for plastering operations in a small space.

Owner:上海蔚建科技有限公司

A kind of warehousing logistics transshipment method

The invention relates to the field of logistics, in particular to a warehousing logistics transfer method. The sorting device used in the method comprises a detection mechanism, a logistics box, a transfer mechanism, a third conveyor belt, a push mechanism, a sorting mechanism and a processing box; The push mechanism can push the logistics boxes to the inside of the sorting mechanism for sorting and output. The sorting mechanism of the present invention is provided with multiple layers up and down, each layer corresponds to a specific destination area, and the second conveyor belt is controlled to rotate to the entrance of the corresponding third conveyor belt according to the destination to be delivered by the package, so as to realize the Items in different regions are automatically distributed to different levels of the sorting mechanism; when the items are output, they can be put into the corresponding unloading ports according to the size of the items, which is convenient for direct loading and unloading according to the size of the items during assembly. At the same time, it is convenient for the neat stacking and stacking of items, avoiding the loss and omission of small items, and improving the speed of item sorting and management.

Owner:深圳市泰际信息科技有限公司

Bridge deck accumulated water diversion drainage anti-pollution system and method

InactiveCN111926697ASimple structureReduce hardware costsMeasurement devicesClosed circuit television systemsWater diversionStormwater

The invention discloses abridge deck accumulated water diversion drainage anti-pollution system and method. Accumulated water on the bridge deckflows into the accumulated water collecting pipeline from the accumulated water collecting structure through the accumulated water collecting pipeline and the accumulated water detectionand diversiondevice; accumulated water entering the accumulated waterdiversion detection device is detected; if accumulated water is polluted, the processor controls the accumulated water detectionand diversion device to discharge accumulated water into the sewage collecting tank from the second drainage end; if accumulated water is not polluted, the accumulated water detection and diversion device is controlled to discharge the accumulated water to the drainage pipe from a first drainage end. The accumulated water detection and diversion device is used for detecting andclassifying rainwater, and then the rainwater is selectively collected or discharged according to the pollution condition of the accumulated water, so that the pollution to a water area is avoided. Accumulated water is subjected to diversion treatment, so that all the accumulated water is prevented from flowing into the sewage collectingtank, the frequency of cleaning the sewage collectingtank is reduced, unpolluted water is prevented from being treated as sewage, and the sewage treatment cost is reduced.

Owner:CHINA UNITED NORTHWEST INST FOR ENG DESIGN & RES

COD-based rain and sewage pipe network intelligent splitting device

InactiveCN109183949ARealize secondary collectionReduce the riverMeasurement devicesSewage drainingLevel sensorEngineering

The invention discloses a COD-based rain and sewage pipe network intelligent splitting device, which comprises a control box, a sewage pump, a liquid level gauge, a COD concentration sensor, an intelligent control system, and an intelligent control system for controlling the start and stop of the sewage pump; the intelligent splitting device comprises a control box, a sewage pump, a liquid level gauge, a COD concentration sensor and an intelligent control system. At least two liquid level data and one COD concentration data are preset in that intelligent control system, which are mar as the starting liquid level, the close liquid level and the opening / closing concentration respectively, and the closing liquid level is higher than the top elevation of the sewage pump; When the liquid levelis higher than the starting liquid level and the COD concentration data is higher than the on-off concentration, start the sewage pump to work; If the COD concentration data is less than the on-off concentration, or the liquid level measured by the level gauge is lower than the off-off liquid level, the sewage pump shall be switched off. The invention can realize the secondary collection of sewage; Can collect initial rainwater, reduce pollutants into the river; Intelligent control system, which can realize automatic rainwater and sewage distribution; Flood discharge and drainage will not be affected.

Owner:宁波点溪环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com