Discharge detecting device of bearing double-end-face processing machine tool

A technology for processing machine tools and detection devices, which is applied in the direction of metal processing equipment, grinding machine parts, manufacturing tools, etc., can solve the problems of low manual detection efficiency and high labor costs, and achieve automatic management, high efficiency and full automation, and reduce Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

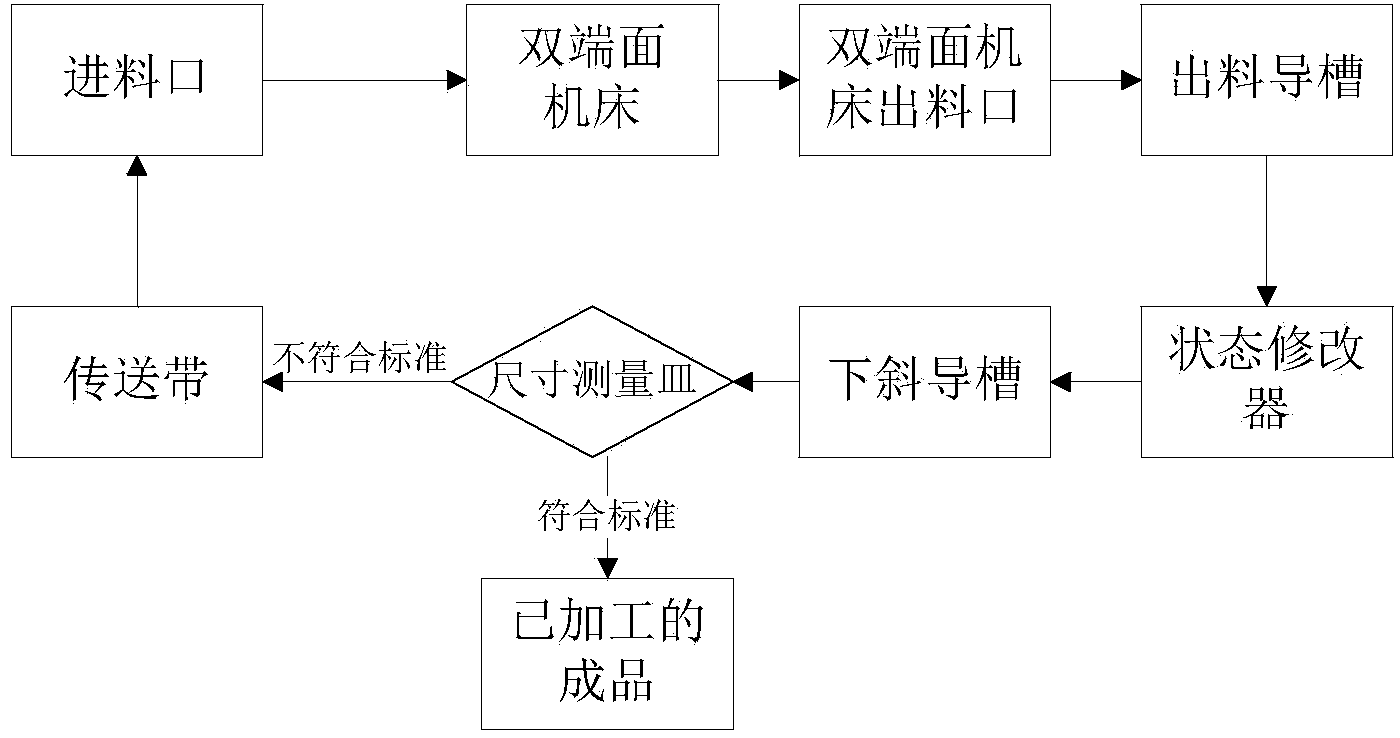

[0016] The present invention is to realize the automatic detection of the discharge port of the double-end machine tool in bearing processing and find out the products that do not meet the requirements, reduce manpower, increase the precision and quality of bearing processing, reduce the number of repeated secondary processing, and realize the double-end processing of bearings. Automatic management of output. The embodiments of the present invention are designed according to the principles of the present invention, and the present invention will be further described below in conjunction with the drawings and specific embodiments.

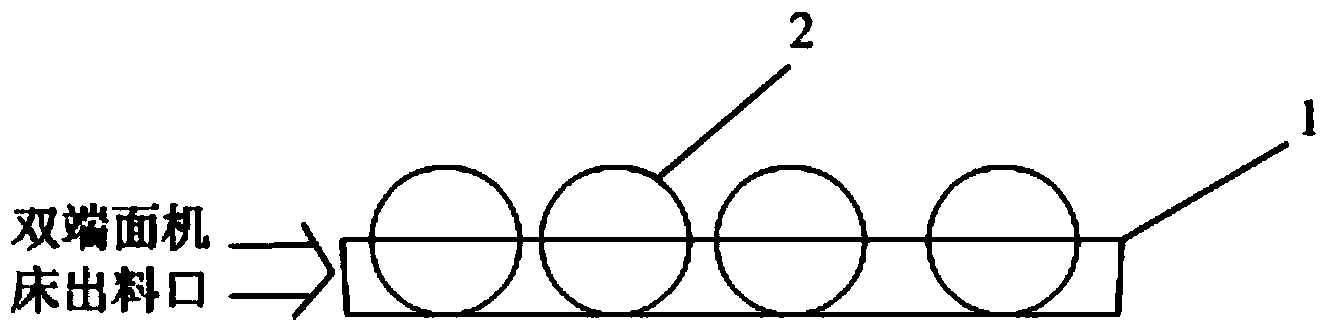

[0017] Such as figure 1 Shown is the working process of the discharge detection device of the bearing double-end surface processing machine tool in this embodiment. The principle is as follows: the bearing first enters the machine tool through the feed port of the machine tool for processing, and then rolls along the guide plate (the iron plate that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com