Clothes dryer with steam function and steam control method

A control method and clothes dryer technology, which are applied in the field of clothes dryers, can solve problems such as steam ejection and residual heat burns of users, and achieve the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

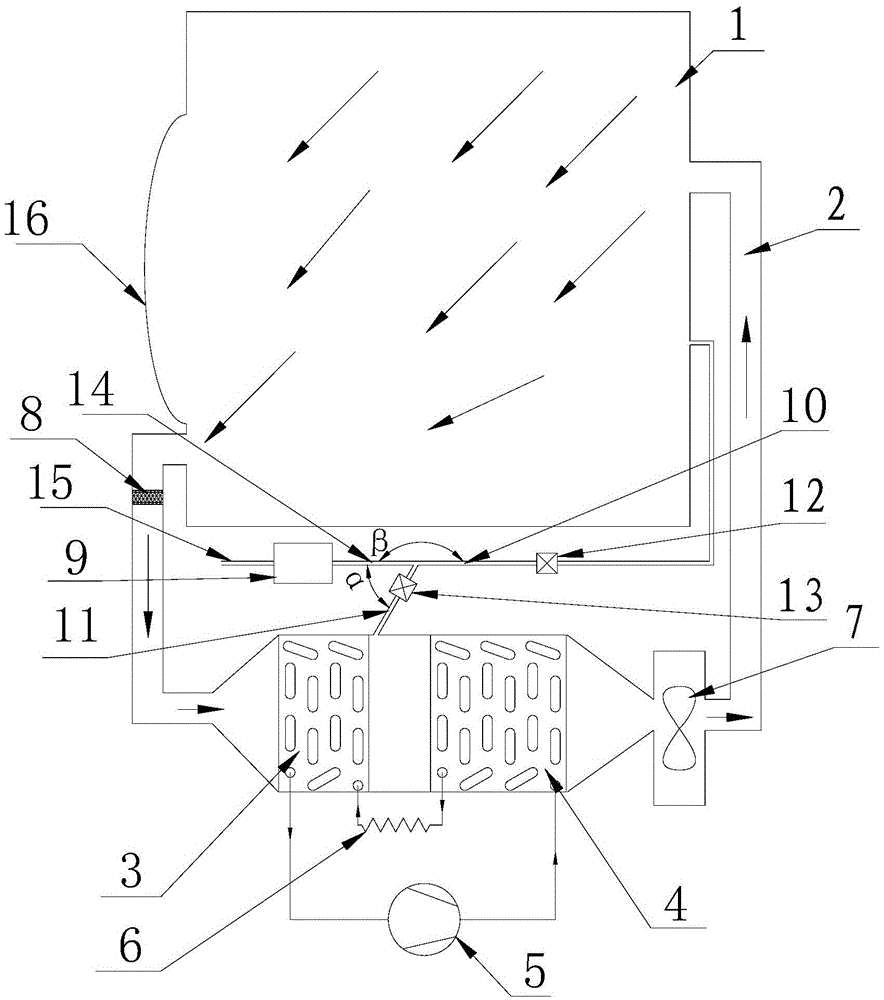

[0044] In this embodiment, the steam generator 9 of the clothes dryer can be any existing steam generator with the following structure: a body forming a chamber with a certain volume is provided, and a chamber for converting water into steam is provided in the chamber. The heating device is provided with a water inlet for water to enter the chamber and an air outlet for steam to flow out of the chamber on the body.

[0045] Such as figure 1 As shown, in the present embodiment, the gas outlet of the steam generator 9 communicates with one end of the gas outlet pipe 14, and the other end of the gas outlet pipe 14 communicates with the first pipeline 10 and the second pipeline 11 respectively, and the first pipeline 10 It communicates with the outer cylinder 1 , and the second pipeline 11 communicates with the drying air passage 2 between the evaporator 3 and the condenser 4 .

[0046] By connecting the second pipeline with the drying air path between the evaporator and the cond...

Embodiment 2

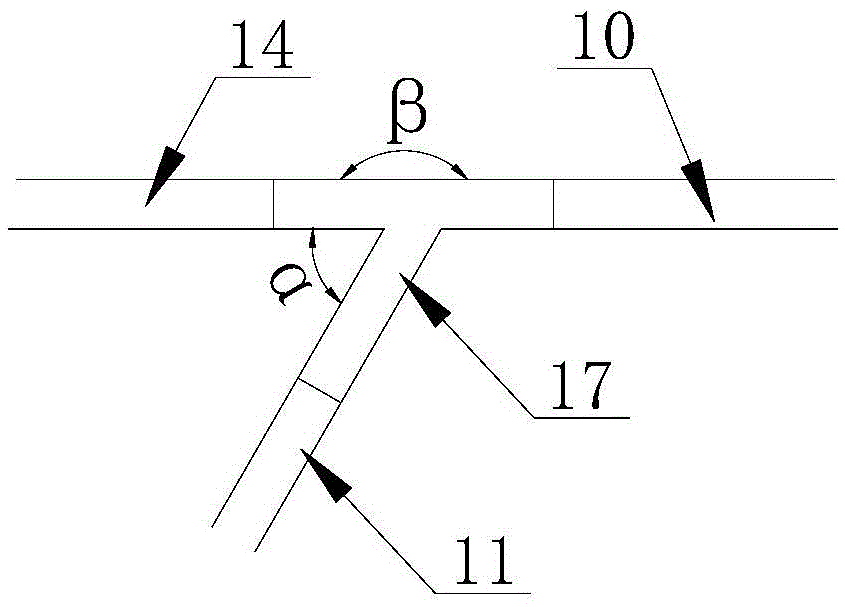

[0054] The difference between this embodiment and the first embodiment above is that: figure 1 As shown, the angle between the axis of the first pipeline 10 and the air outlet pipe 14 on the clothes dryer is larger than the angle between the axis of the second pipeline 11 and the air outlet pipe 14 . Through the above setting, the three-way structure at the intersection of the first pipeline 10, the second pipeline 11 and the outlet pipe 14 has a Venturi effect, so that the steam with a lower density flowing in from the outlet pipe 14 flows to the first pipeline 10, The non-vaporized water with higher density flowing into the air outlet pipe 14 flows to the second pipeline 11 .

[0055] Such as figure 2 As shown, in this embodiment, one end of the gas outlet pipe 14 communicates with the gas outlet of the steam generator 9 , and the other end communicates with the first pipeline 10 and the second pipeline 11 through the tee 17 . Described tee 17 comprises air inlet section,...

Embodiment 3

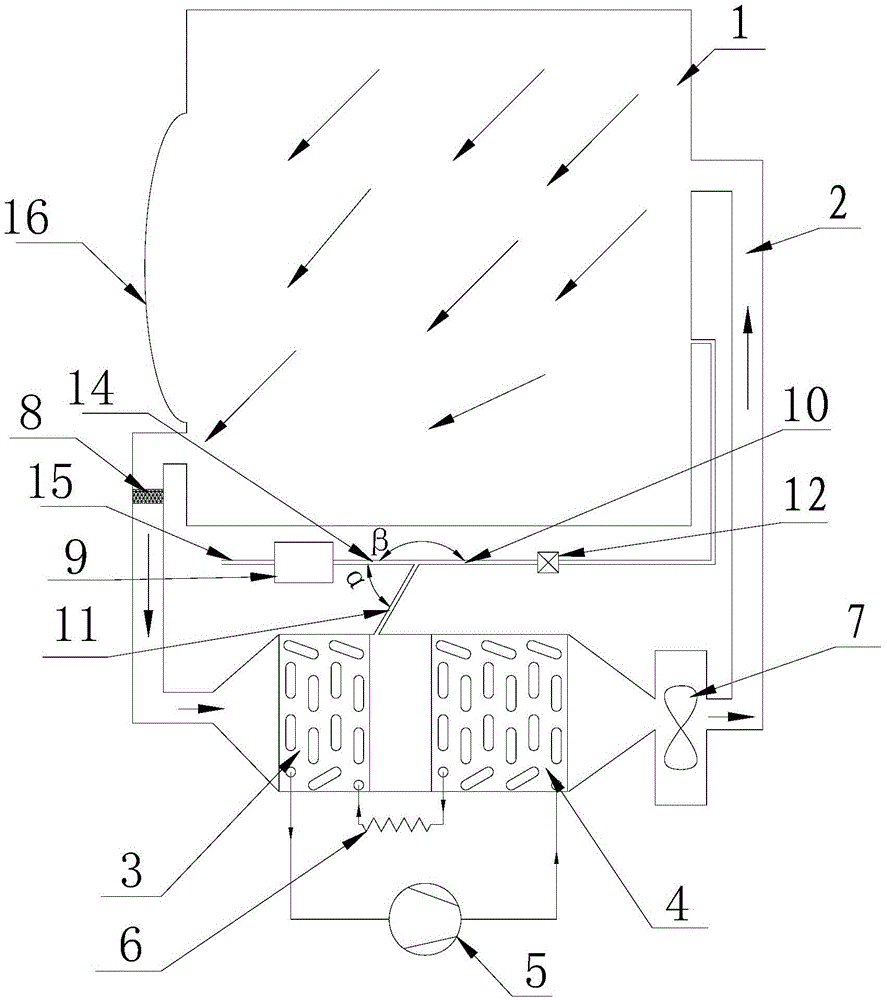

[0063] The difference between this embodiment and the second embodiment above is that: image 3 As shown, only the first control valve 12 is provided on the first line 10 . During the normal steam washing process of the clothes dryer, the medium flowing through the pipeline is automatically controlled through the three-way structure with Venturi effect, so that the gaseous water vapor flows into the first pipeline, and the liquid unvaporized water flows into the second pipeline. In order to avoid the situation that the second control valve needs to be arranged on the second pipeline, the number of control valves required on the pipeline is reduced, and the production cost is reduced.

[0064] In this embodiment, the corresponding states during the working process of the clothes dryer are as follows:

[0065] State 1: During the normal steam process of the clothes dryer, the door body 16 of the clothes dryer is in a closed state, and the first control valve 12 is opened, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com