A heat-resistant austenitic stainless steel with high structural stability at 700℃

A technology of austenitic stainless steel and stability, applied in the field of heat-resistant stainless steel, can solve the problems of insufficient mechanical properties and corrosion resistance, poor structure stability, etc., and achieve excellent high-temperature mechanical properties and corrosion resistance, good processing performance, melting simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Fe 50.22 Cr 24.62 Ni 22.23 Mo 0.73 Ti 0.09 Nb 0.18 W 0.70 mn 0.78 Si 0.40 C 0.05 (wt.%) alloy

[0016] Step 1: Alloy Preparation

[0017] The composition alloy adopts high-purity components, and the elements are proportioned according to the mass percentage of the alloy composition; the proportioned mixture is smelted several times in a non-consumable vacuum arc melting furnace under the protection of Ar gas to obtain a uniform mass of about 60g alloy ingot. Then the alloy ingot is hot-rolled at 1150°C. Before the hot-rolling treatment, the alloy ingot is kept at 1150°C for 30 minutes, and then it is hot-rolled out of the furnace. The deformation amount is about 10% each time. After each pass of hot-rolling Return to the furnace for 5 minutes of heat preservation, the total amount of rolling deformation is 80%, and the thickness of the final rolled plate is 1.4mm. The hot-rolled samples were subjected to solution treatment at 1150°C / 30min, water co...

Embodiment 2

[0022] Example 2 Fe 50.56 Cr 24.68 Ni 22.28 Mo 0.73 Ta 0.34 Nb 0.18 mn 0.78 Si 0.40 C 0.05 (wt.%) alloy

[0023] Step 1: Alloy Preparation

[0024] Alloy preparation is the same as Step 1 in Example 1.

[0025] Step 2: Alloy structure and mechanical properties test

[0026] Using OM, SEM and XRD to detect the microstructure and structure of the alloy after stabilization treatment, the results show that the alloy is a single austenite structure, and more fine MC-type carbides are precipitated in the matrix; the stabilization is tested by MTS universal tensile testing machine The mechanical property parameters of the plate samples after treatment are: σ 0.2 =227MPa, σ b =545MPa, δ=54.5%.

[0027] Step 3: Study on the Stability of the Alloy Structure

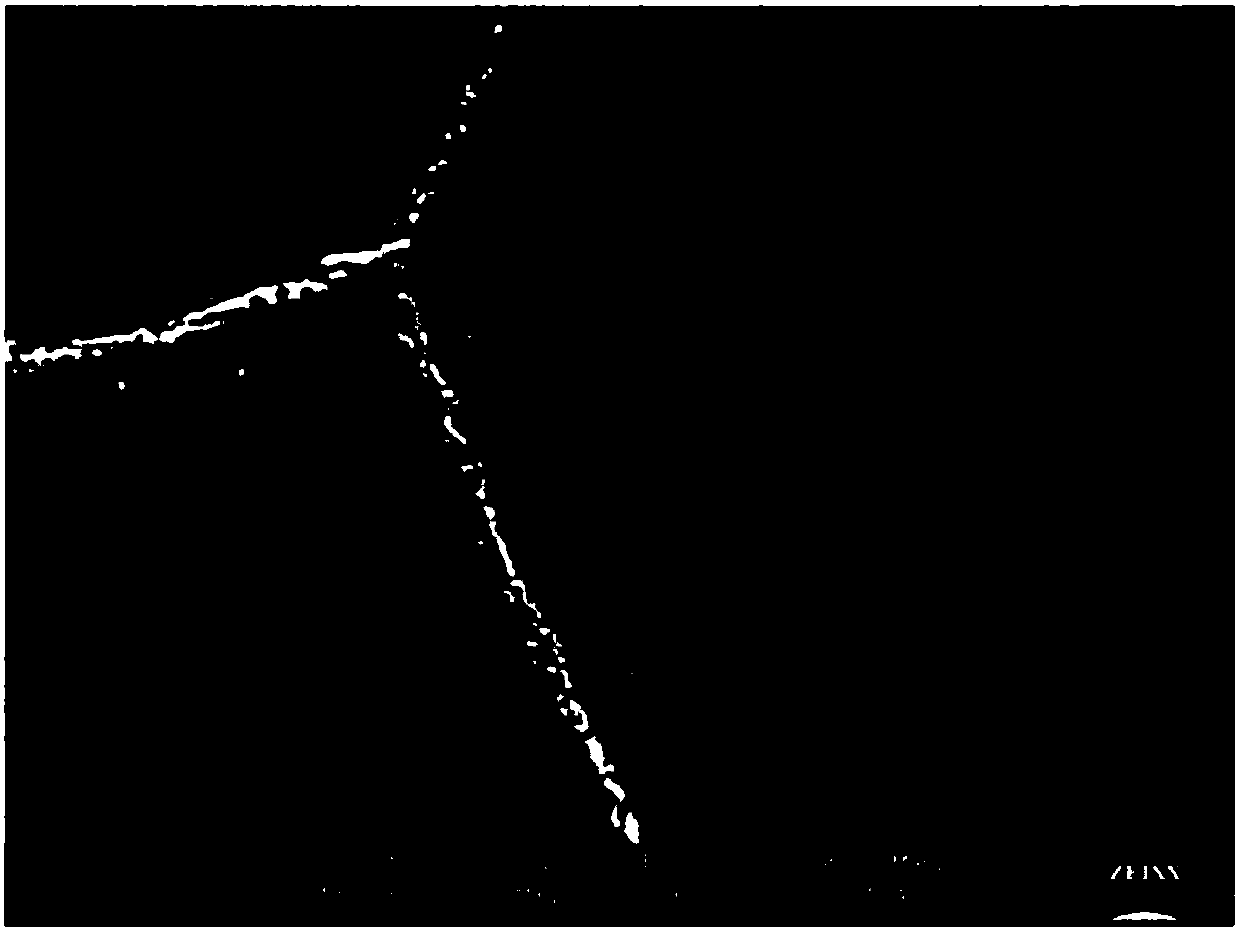

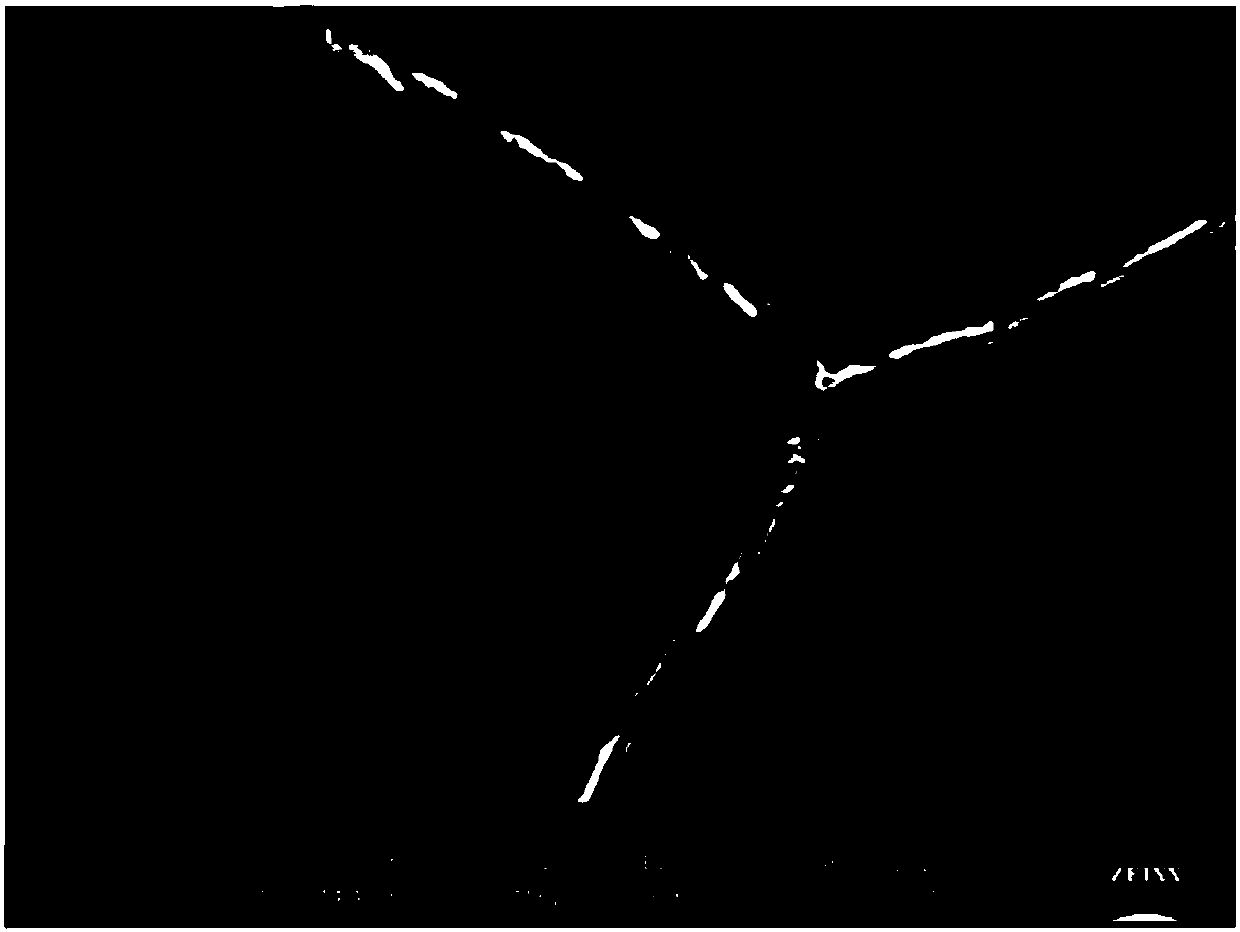

[0028] In order to study the stability of the alloy structure, the stabilized sample was subjected to aging treatment at 700°C for 408 hours, and the structure was observed by OM and SEM. The results are shown in Figu...

Embodiment 3

[0029] Example 3 Fe 50.92 Cr 24.76 Ni 22.36 Mo 0.37 Zr 0.35 mn 0.79 Si 0.40 C 0.05 (wt.%) alloy

[0030] Step 1: Alloy Preparation

[0031] Alloy preparation is the same as Step 1 in Example 1.

[0032] Step 2: Alloy structure and mechanical properties test

[0033] Using OM, SEM and XRD to detect the microstructure and structure of the alloy after stabilization treatment, the results show that the alloy is a single austenite structure, and a small amount of fine MC-type carbides are precipitated in the matrix; the stabilization treatment is tested by MTS universal tensile testing machine The mechanical property parameters of the rear plate samples are: σ 0.2 =200MPa, σ b =501MPa, δ=57.1%.

[0034] Step 3: Study on the Stability of the Alloy Structure

[0035] In order to study the stability of the alloy structure, the stabilized sample was subjected to aging treatment at 700 ° C for 408 h, and the structure was observed by OM and SEM. The results are shown in Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com