Amplitude and frequency regulating device and road roller

A technology of road rollers and amplitude modulation, applied in the field of road rollers, can solve the problems of over-compacting of road rollers, the inability to adjust the phase of the eccentric shaft, and the inability to adjust the phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

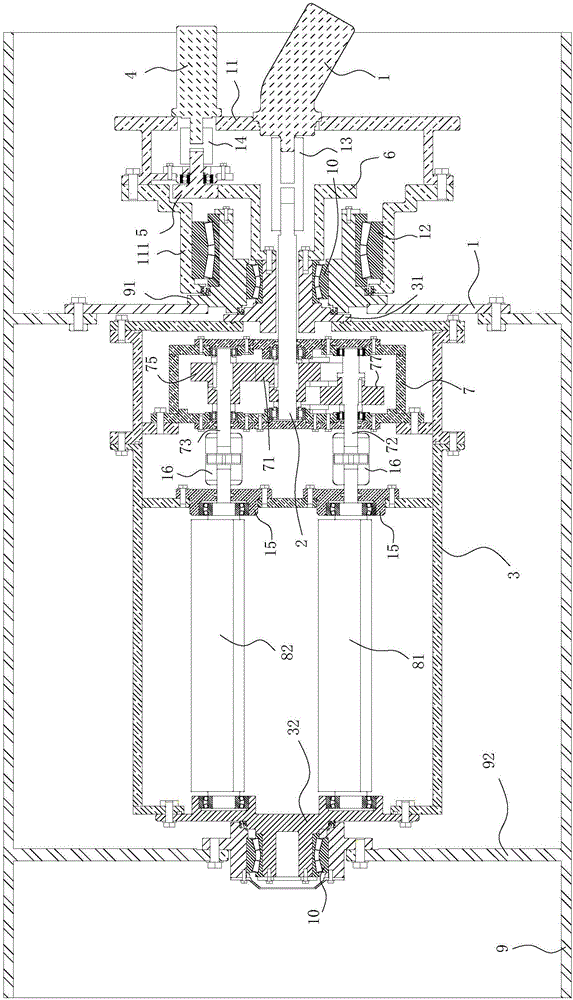

[0032] Such as Figure 1-4 As shown, in this embodiment, an amplitude and frequency modulation device is provided, which includes a first driving mechanism 1, and an output end of the first driving mechanism 1 is connected to a first transmission shaft 2, and the first transmission shaft 2 and the frequency modulation mechanism Connected, the frequency modulation mechanism is fixedly connected with the vibration box 3; wherein the frequency modulation mechanism is used to adjust the vibration frequency of the roller, so that the road surface is compacted by vibration as required;

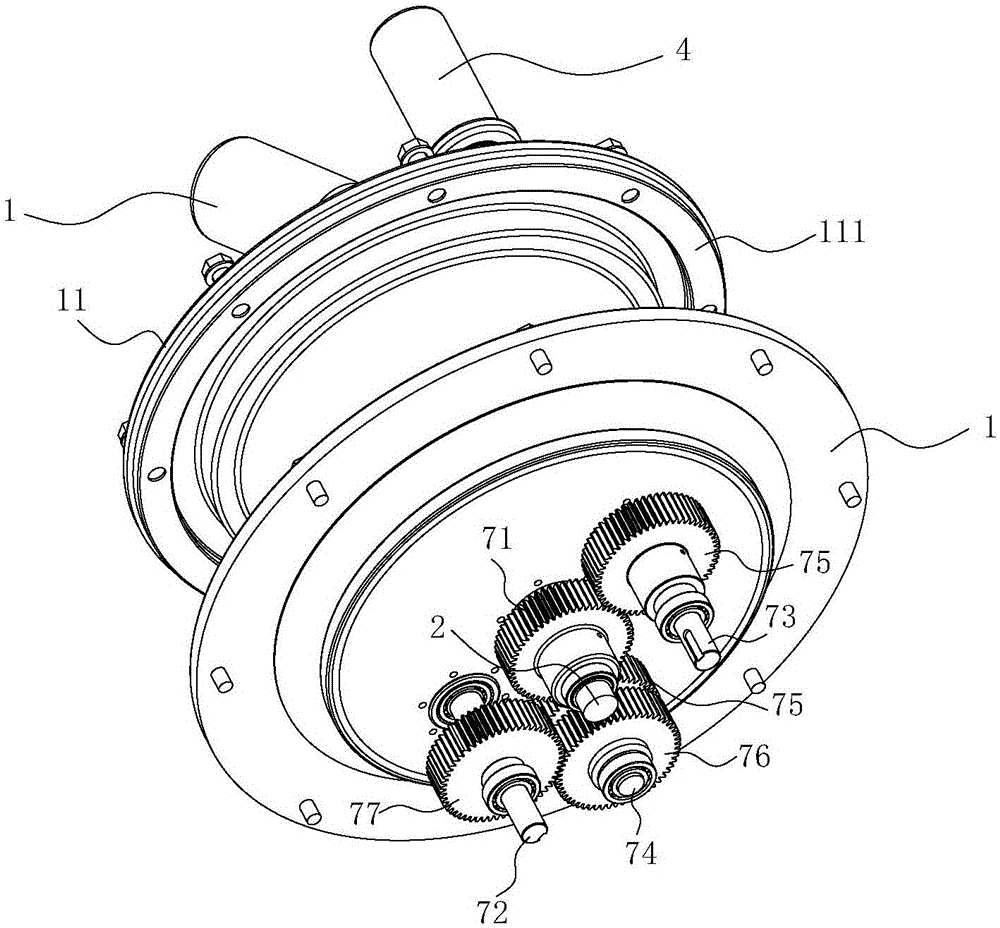

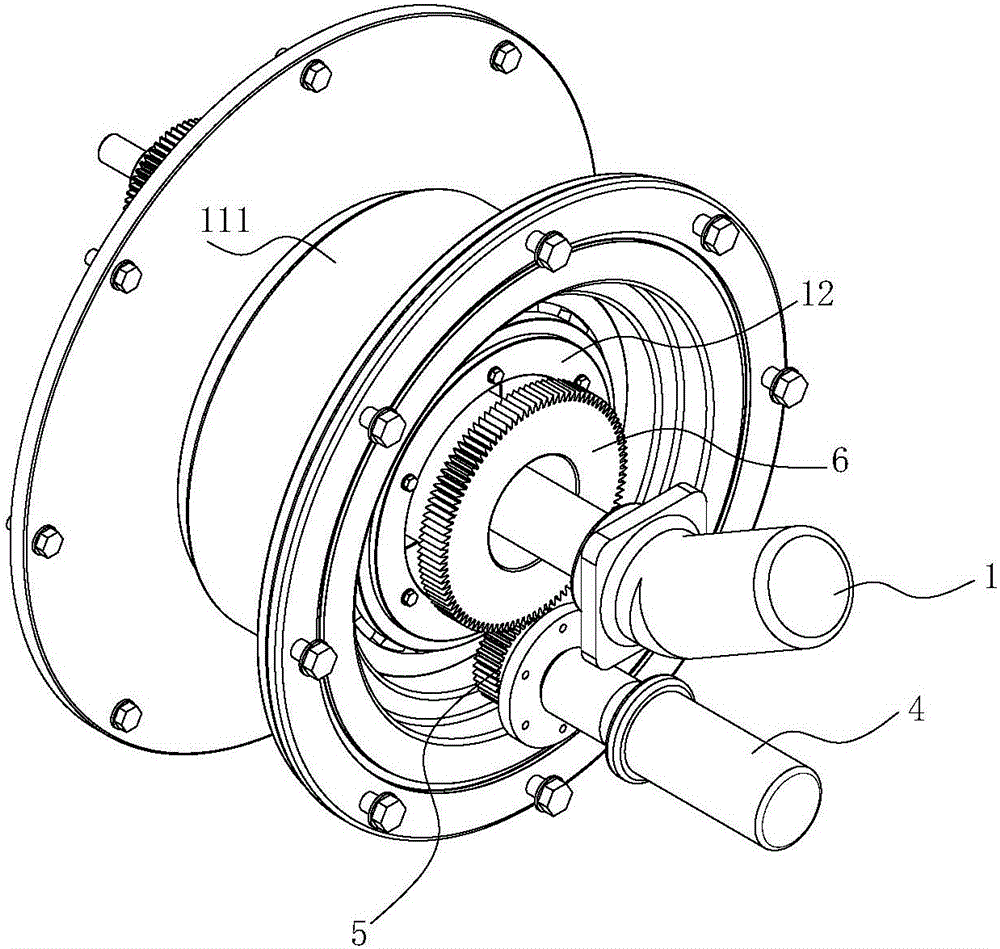

[0033] Amplitude modulation mechanism, which is used to adjust the phase between eccentric shafts, such as image 3 As shown, the amplitude modulation mechanism includes an amplitude modulation motor 4, the output end of the amplitude modulation motor 4 is connected with an amplitude modulation driving gear 5, the amplitude modulation driving gear 5 and the amplitude modulation driven gear 6 mesh with e...

Embodiment 2

[0047] This embodiment provides a road roller, which includes the amplitude and frequency modulation device as described in the first embodiment. The roller is equipped with an amplitude and frequency modulation device, which can meet the requirements of different paving materials, different paving thicknesses, and different compaction stages. The roller in this embodiment can adjust the amplitude according to needs, and realize any adjustment from the minimum amplitude to the maximum amplitude.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com