An earthquake-damaged replaceable steel beam structure

A steel beam and section steel technology, applied in the field of earthquake-damaged replaceable steel beam structures, can solve the problems of difficult maintenance and replacement of steel beams and high maintenance and replacement costs, and achieve the effects of reduced transportation difficulty, low repair costs, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

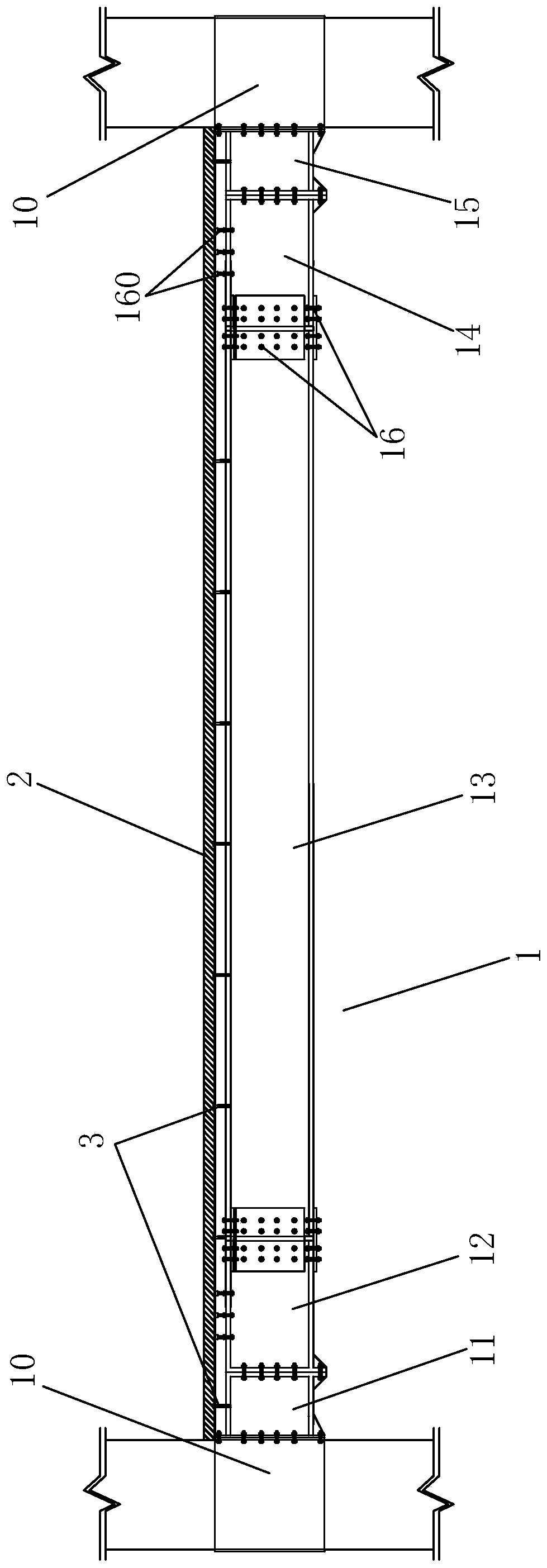

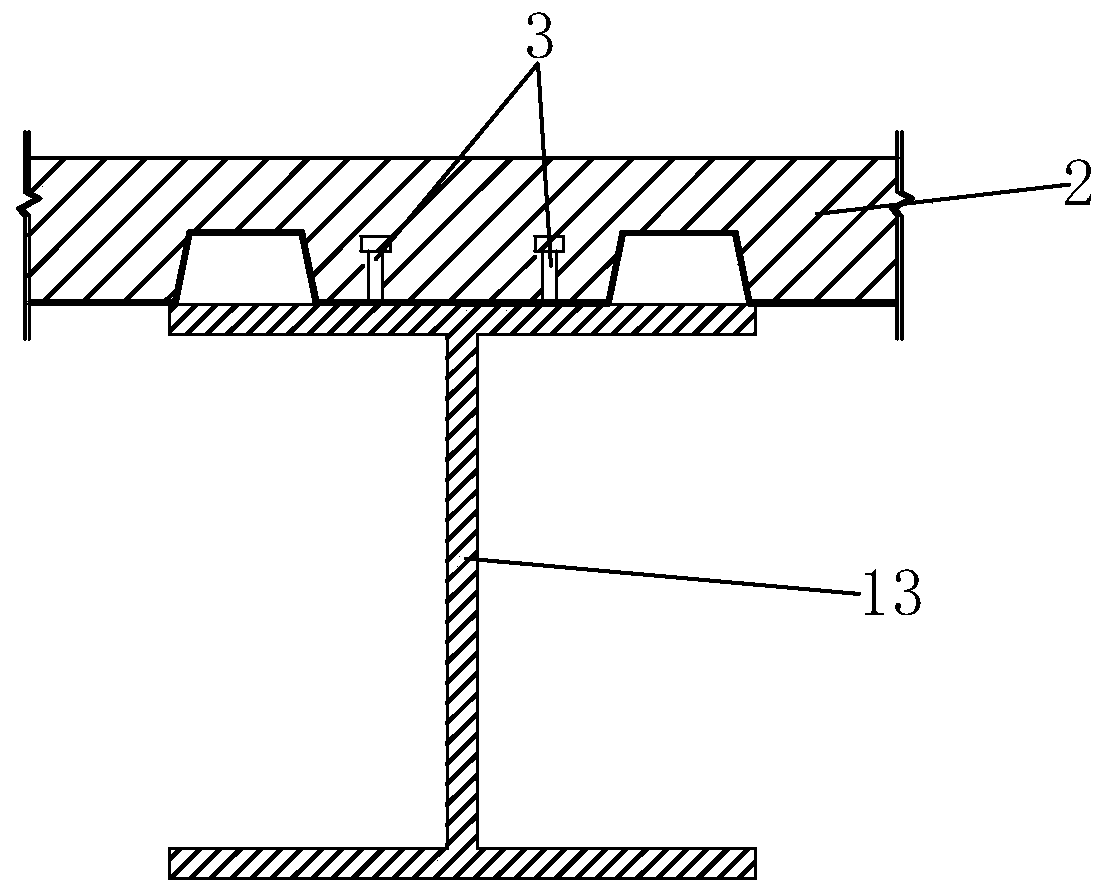

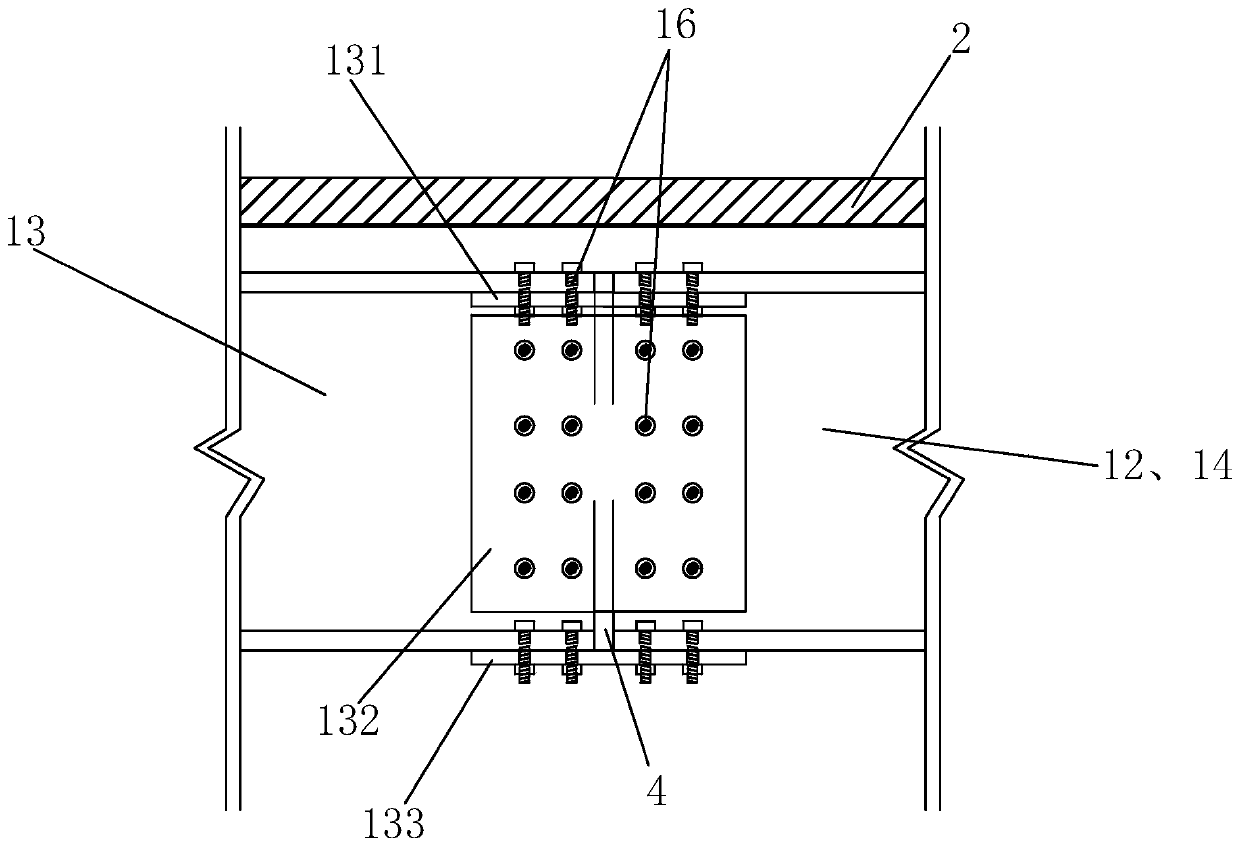

[0035] Such as figure 1 As shown, a seismically damaged replaceable steel beam structure includes a composite steel beam 1 and a composite floor 2 connected to the composite steel beam 1, and the composite steel beam 1 includes a first end steel beam connected in sequence 11. A first energy-dissipating section steel beam 12, a mid-span steel beam 13, a second energy-dissipating section steel beam 14 and a second end steel beam 15, the first end steel beam 11 and the second end The steel beams 15 are respectively connected to the end columns 10 on both sides, and the above-mentioned steel beams are all I-shaped beams, such as figure 2 As shown, the mid-span steel beam 13 is connected to the composite floor 2 through welding studs 3 . Such as Figure 5 As shown, the steel beam 12 of the first energy dissipation section and the steel beam 14 of the second energy dissipation section are both connected to the composite floor 2 through the second high-strength friction bolt 160 w...

Embodiment 2

[0042] The structure and connection mode of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 11 with 12 As shown, the lower ends of the first friction plate 17 and the second friction plate 18 are connected with the lower ends of the first and second end steel beams 11 and 15 and the lower ends of the first and second energy dissipation section steel beams 12 and 14 flush, the first end steel beam 11 and the first energy-dissipating section steel beam 12 and the second end steel beam 15 and the second energy-dissipating section steel beam 14 are connected through the lower flange splicing plate 133, And the lower flange splicing plate 133 passes through the first high-strength friction bolt 16 and the first end steel beam 11, the second end steel beam 15, the first energy-dissipating section steel beam 12 and the second energy-dissipating section steel beam 14 connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com