Hollow fiber and solid core fiber butting and packaging system and method thereof

A hollow-core optical fiber and packaging system technology, applied in the field of high-stability docking packaging, can solve problems such as difficult application, fragile solid-core optical fiber, and difficult operation, and achieve the effects of high fiber coupling efficiency, high strength, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

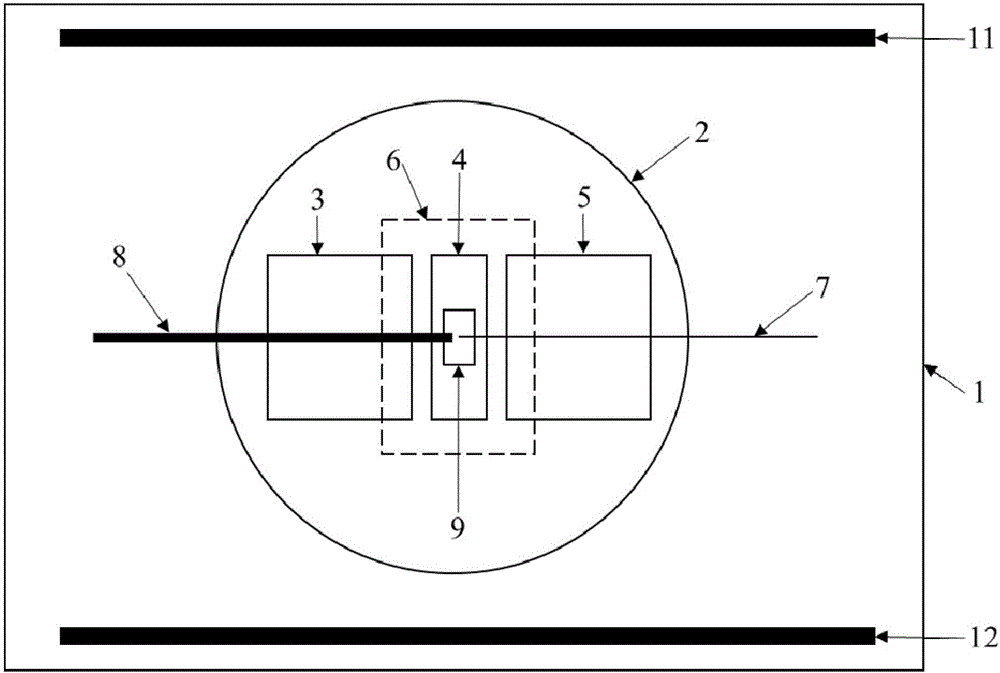

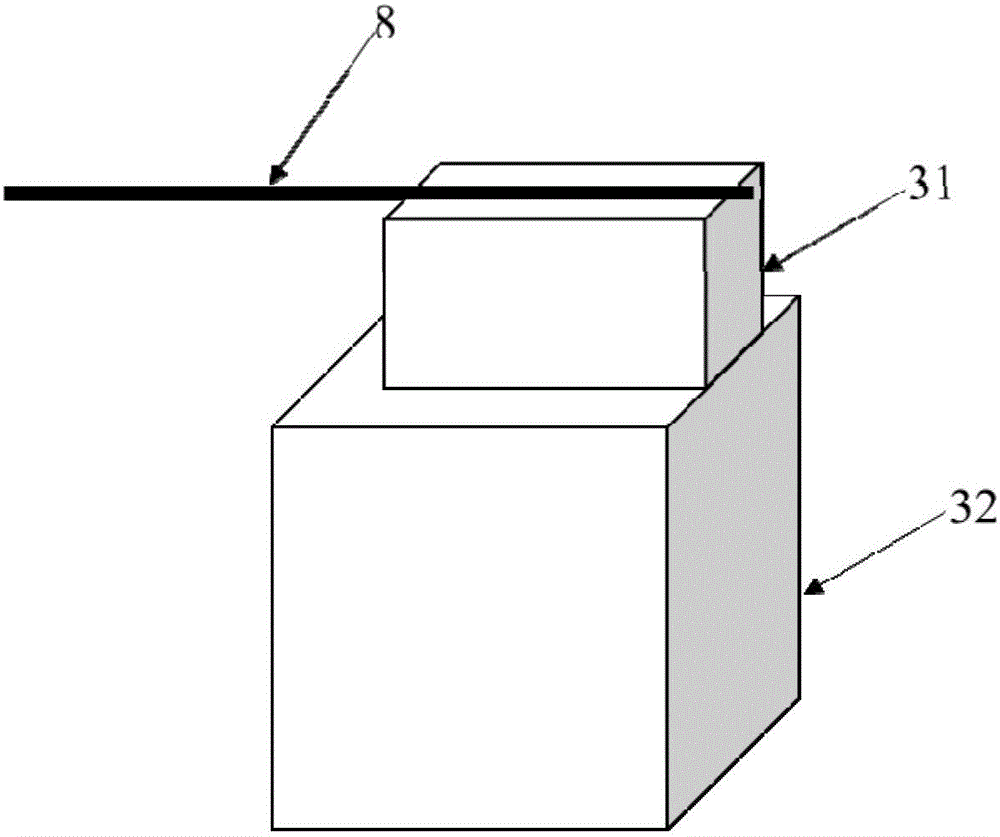

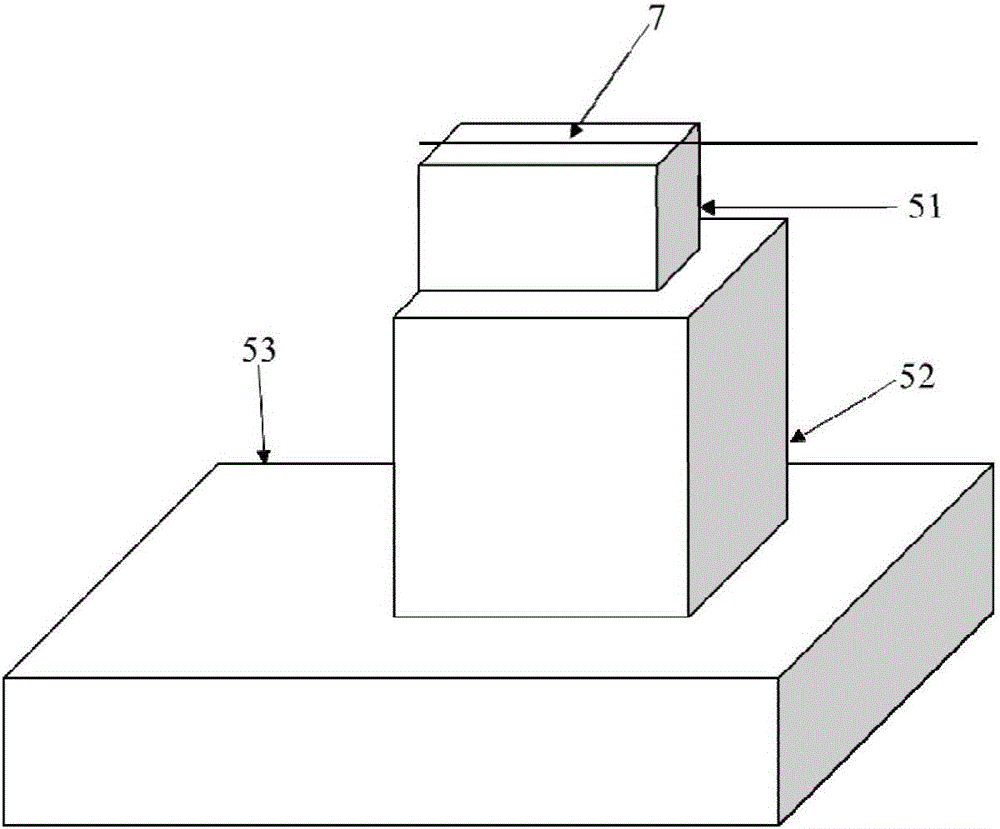

[0047] like figure 1 As shown, the hollow-core optical fiber and solid-core optical fiber high-precision docking packaging system of the present invention includes an optical platform 1 with left and right guide rails, a two-dimensional manual linear displacement and rotation platform 2, a docking hollow-core optical fiber loading module 3, and a solid-core optical fiber docking module. Optical fiber loading module 5, docking point fiber optic fixture loading base 4, optical fiber packaging fixture 9 and docking point two-dimensional CCD video surveillance module 6, described fiber optic packaging fixture 9 is installed on the docking point fiber optic fixture loading base 4 for adjusting fiber packaging The relative position and height of the fixture 9, the described docking hollow-core optical fiber loading module 3, docking solid-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com