Liquid self-help injection device, self-help injection and filling method, remote monitoring method

A technology for filling devices and filling pipes, which is applied in remote supervision, liquid self-service filling devices, and self-service filling fields. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

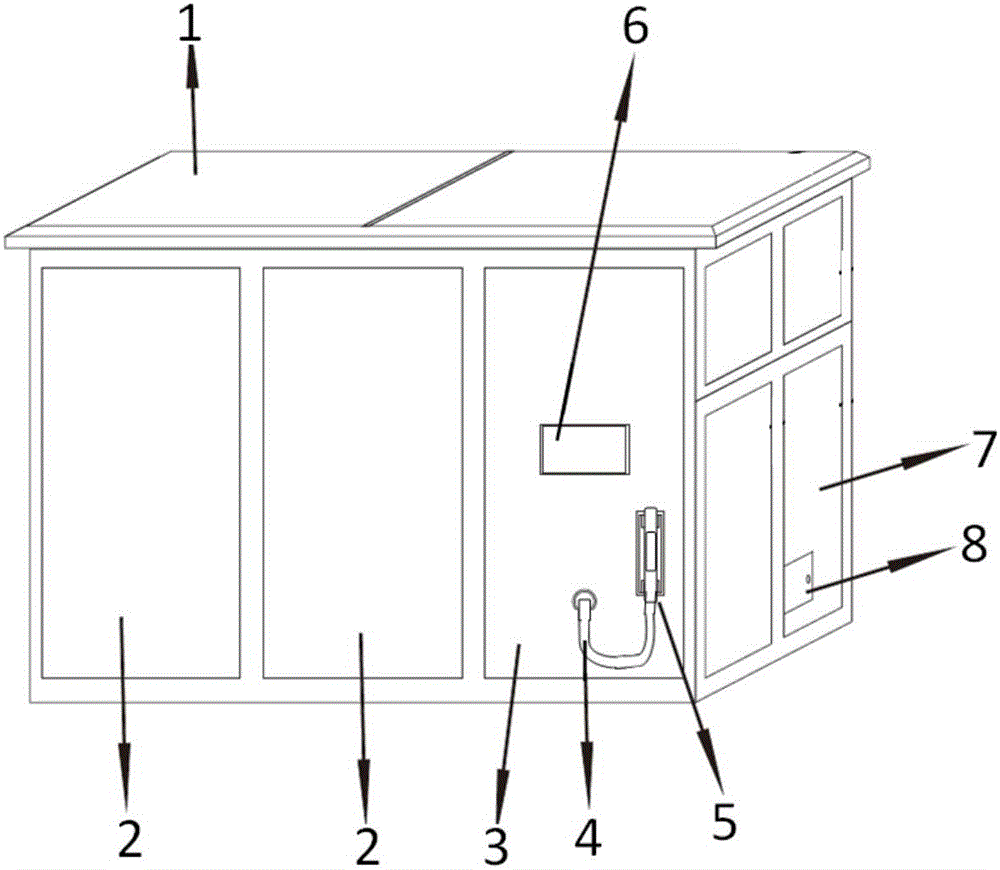

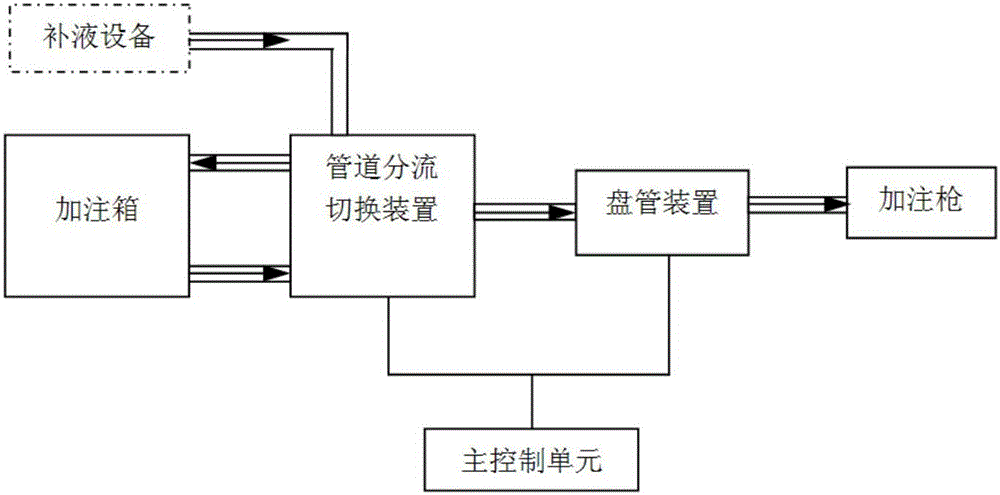

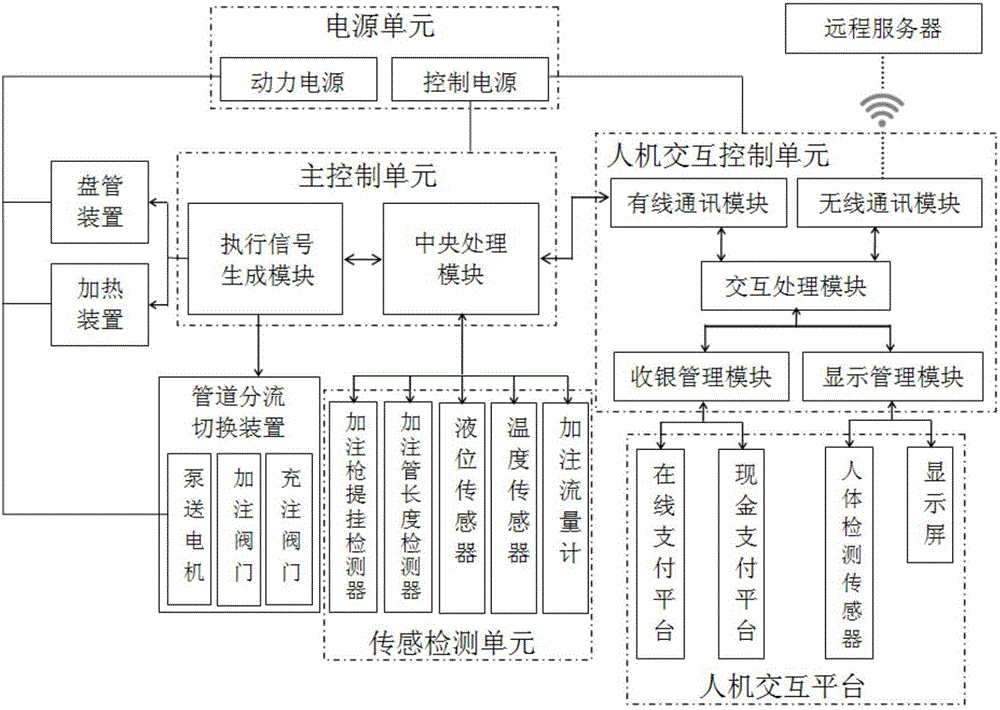

[0045] Firstly, the overall composition and structure of the intelligent liquid self-filling device of the present invention will be described. The liquid self-filling device of the present invention is mainly used for self-filling of liquids, preferably self-filling of urea solution for vehicles, and this self-filling operation process has a high degree of intelligence and automation, which fully meets the requirements of Unattended fluid refill requirements. Specific as attached figure 1 As shown, the intelligent self-service filling device as a whole includes: shell box 1, filling box 2, control cabinet 3, filling pipe 4, filling gun 5, power supply unit, human-computer interaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com