Flexible electroluminescent X-ray image memory display panel

An electroluminescent layer and X-ray technology, applied in the field of X-ray imaging applications, can solve the problems of complex and expensive reading equipment and display devices, and achieve the effects of improved definition, clear and accurate patterns, and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

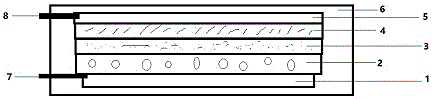

[0017] A flexible electroluminescent X-ray image memory display board, which comprises: a flexible transparent conductive layer 1, an electroluminescent layer 2, an insulating layer 3, a memory layer 4, a metal electrode layer 5, a sealing protection layer 6, and a flexible transparent conductive layer Lead 7, metal electrode layer lead 8; characterized in that: the flexible transparent conductive layer is made of flexible PET film conductive material, the electroluminescent layer is made of electroluminescent material, and the insulating layer 3 is made of barium titanate powder material. Formed; the memory layer is made of zinc oxide materials, which constitute a flexible memory imaging display panel. When the target object is placed between the X-ray light source and the flexible memory imaging display board, the flexible memory imaging display board is energized and emits light. After the X-ray light source instantly releases X-rays, the image of the memory target object is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap