Phase shifter transmission device

A transmission device and phase shifter technology, which is applied to electrical components, antennas, etc., can solve the problems of stuck, long lateral transfer distance, and wide arrangement of multi-frequency antenna phase shifters, so as to reduce installation volume and effectively utilize The effect of space and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

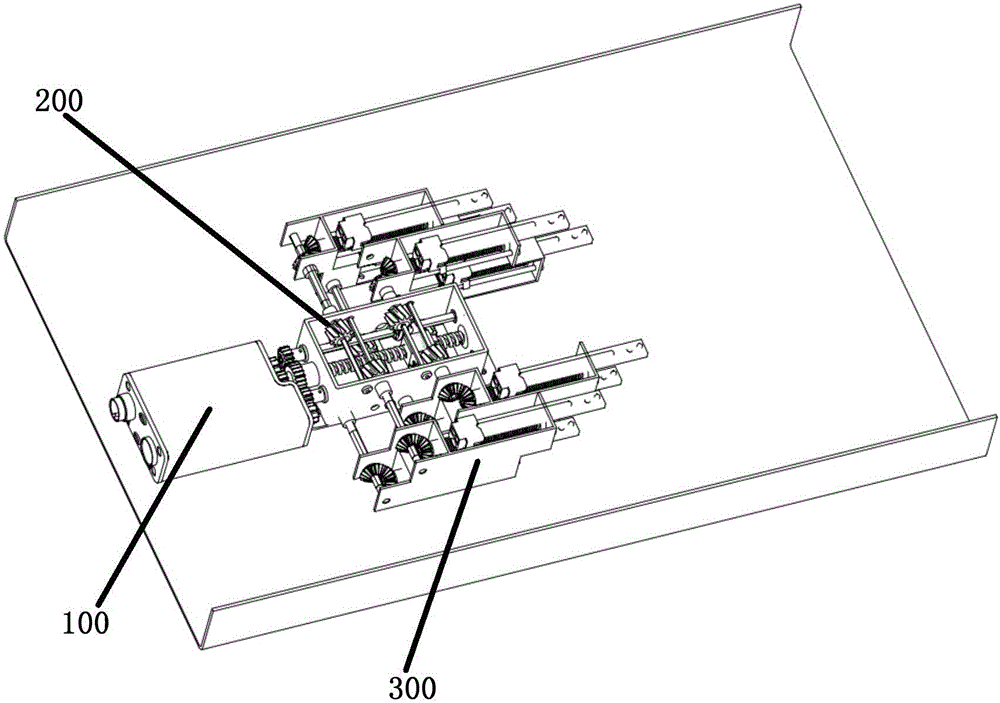

[0025] The phase shifter transmission device of the embodiment of the present invention includes: RCU motor part 100, position selection part 200 and pull rod part 300, wherein, RCU motor part 100 is pluggably connected with position selection part 200, and position selection part 200 can also be It is connected with the tie rod part 300 in a plug-in manner.

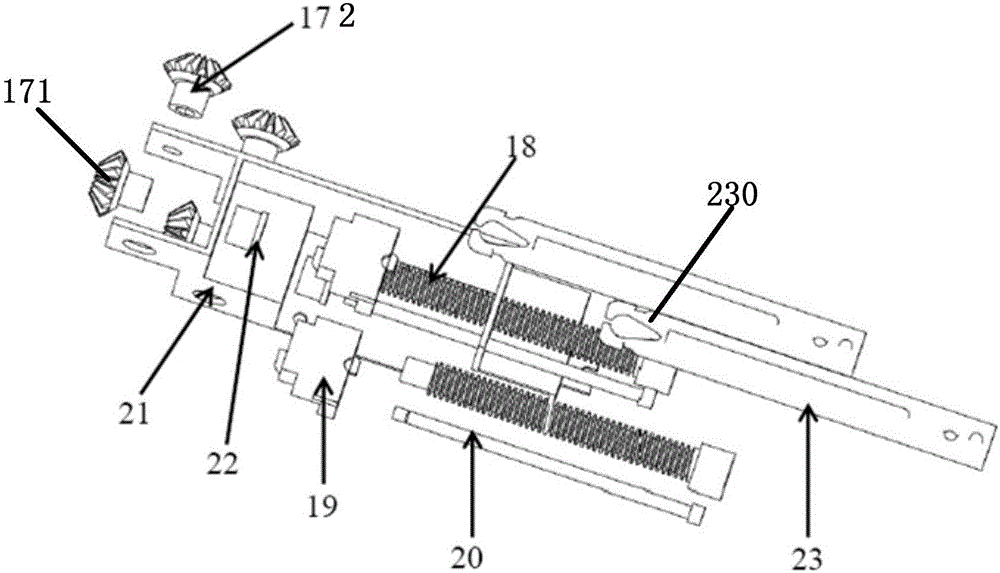

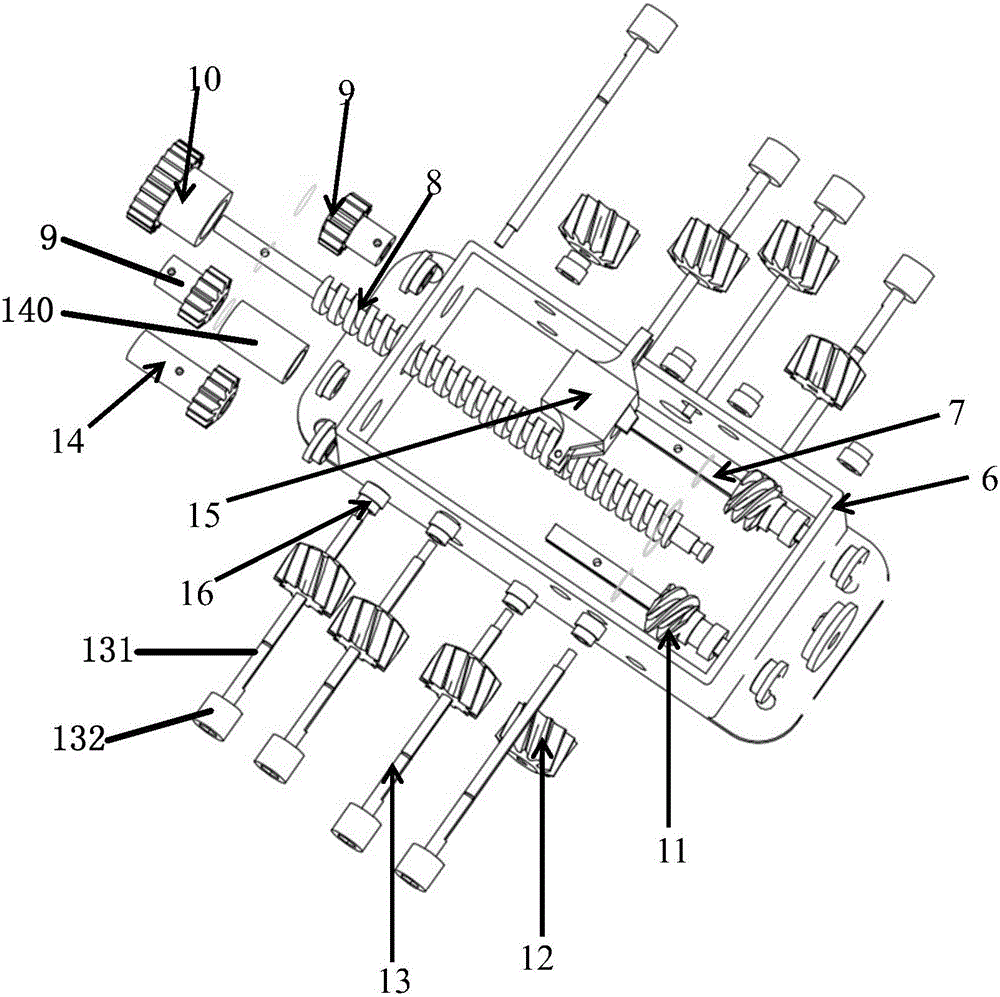

[0026] In a specific application embodiment, the position selection component 200 includes: a cavity 6, a second screw 8 and at least one sliding rod 7 that are rotatably connected to an opposite side wall of the cavity 6, and the sliding rod 7 is arranged in parallel The second screw 8 side. Preferably, a pair of sliding rods 7 can be assembled symmetrically and parallelly on both sides of the second screw rod 8 . Wherein, the second screw rod 8 is sleeved with a second nut 15 that can linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com