Gas overflowing type gas liquid reaction equipment

A technology of gas-liquid reaction and overflow type, which is applied in the direction of chemical methods, dissolution, mixers, etc. that make liquids and gaseous media react, and can solve problems such as energy loss, low reaction efficiency, and long reaction time, and achieve contact Increase the area, increase the contact area, and solve the effect of large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

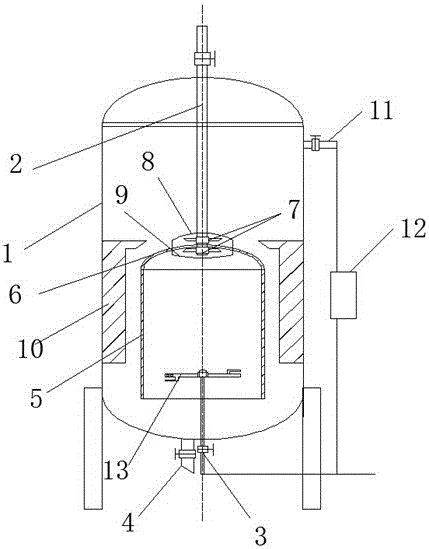

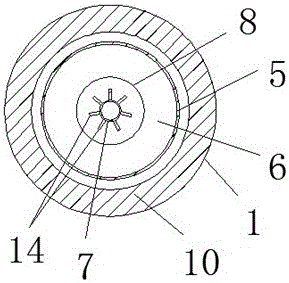

[0014] Embodiment 1: as figure 1 and 2 Shown is a kind of overflow type gas-liquid reaction equipment, the described reaction equipment is a sealed housing 1, the top of the housing 1 is provided with a liquid inlet pipe 2, and the bottom of the housing 1 is provided with an air inlet pipe 3 and a discharge pipe. Pipe 4, the middle part of the housing 1 is provided with a cylindrical overflow tube 5, the top of the overflow tube 5 is provided with an arc-shaped sealing top cover 6, and the bottom of the overflow tube 5 communicates with the housing 1, The liquid inlet pipe 2 is connected to the sealing top cover 6, and the outside and the inside of the sealing top cover 6 are provided with a symmetrically installed liquid separator disc 7, and the liquid separator disc 7 is connected to the liquid inlet pipe 2, and the liquid separator 7 is connected to the liquid inlet pipe 2. A plurality of liquid pipes 14 are uniformly distributed on the liquid separating disk 7, and the t...

Embodiment 2

[0015] Embodiment 2: as figure 1 and 2 As shown, the liquid separating disc 7 above the sealing top cover 6 is provided with a downwardly curved arc-shaped shunt baffle 8, and the liquid separating disc 7 below the sealing top cover 6 is provided with an upwardly curved secondary arc-shaped divider. Liquid baffle 9; through the combination of the arc-shaped shunt baffle 8 and the secondary arc-shaped liquid-separating baffle 9, the liquid discharged from the liquid-distributing disk 7 above the sealing top cover 5 is guaranteed to flow downward, and the liquid below the sealing top cover 5 is divided The liquid discharged from the liquid disc 7 flows upwards, so that the discharged liquid flows down slowly along the side wall of the overflow tube 5 .

Embodiment 3

[0016] Embodiment 3: as figure 1 and 2 As shown, the upper part of the housing 1 is provided with an exhaust pipe 11, and the exhaust pipe 11 is connected to the intake pipe 3 through an air pump 12 and a return line; The return pipe is used for backflow, which is convenient for making full use of the gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com