sot shape integrated circuit chip test and sorting device

A technology for testing integrated circuits and chips, applied in electronic circuit testing, measuring devices, sorting, etc., can solve problems affecting chip detection efficiency, difficulty in transmission, and positioning, and achieve cost savings, efficiency improvement, and high-efficiency detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

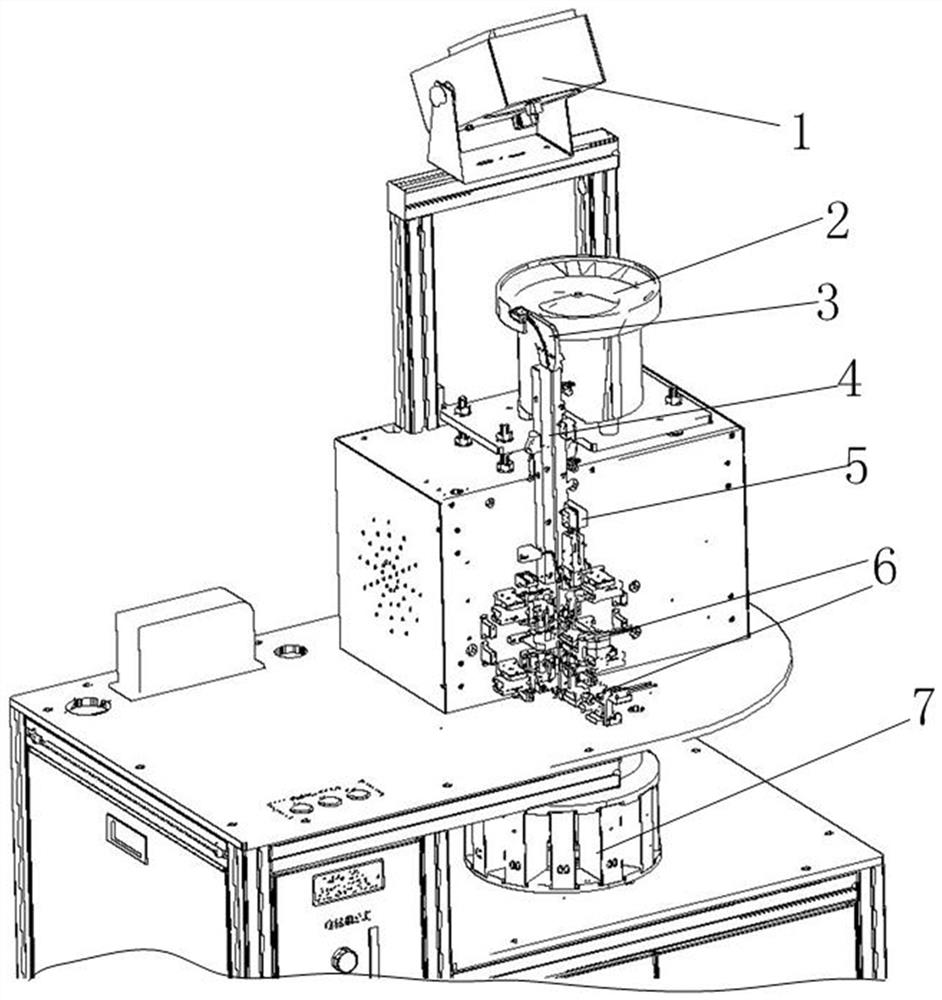

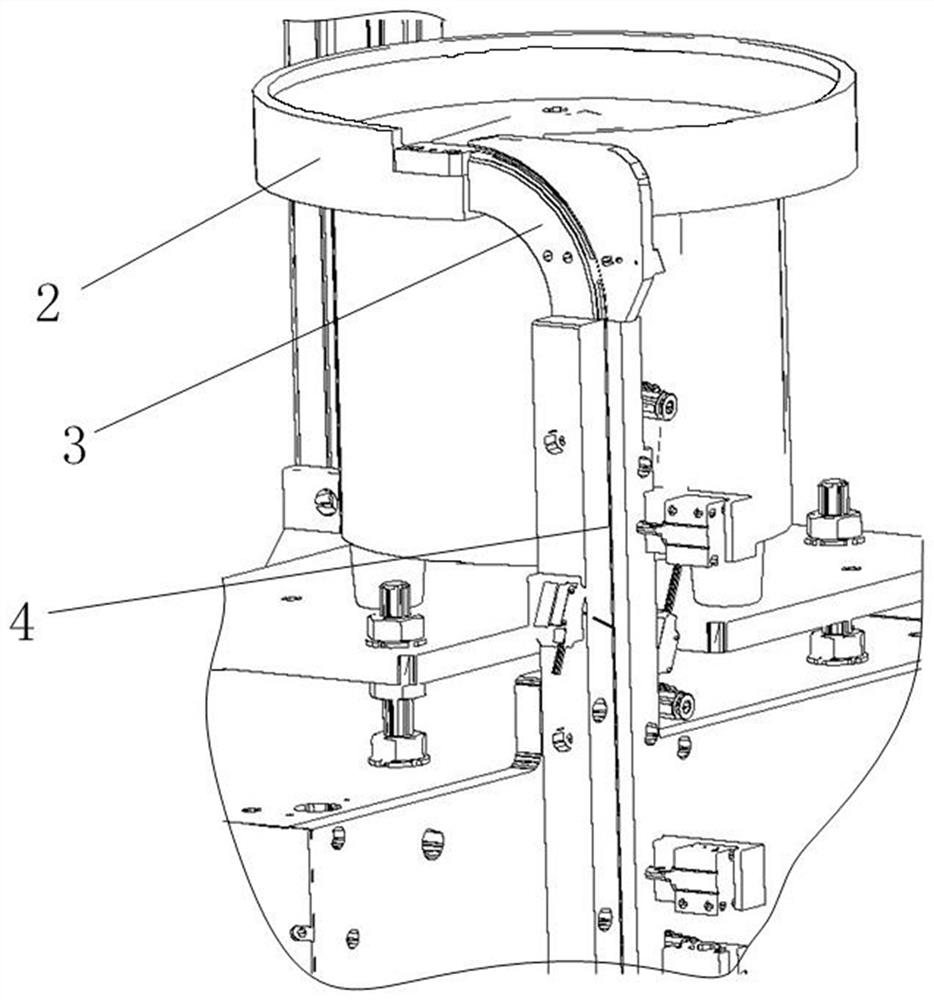

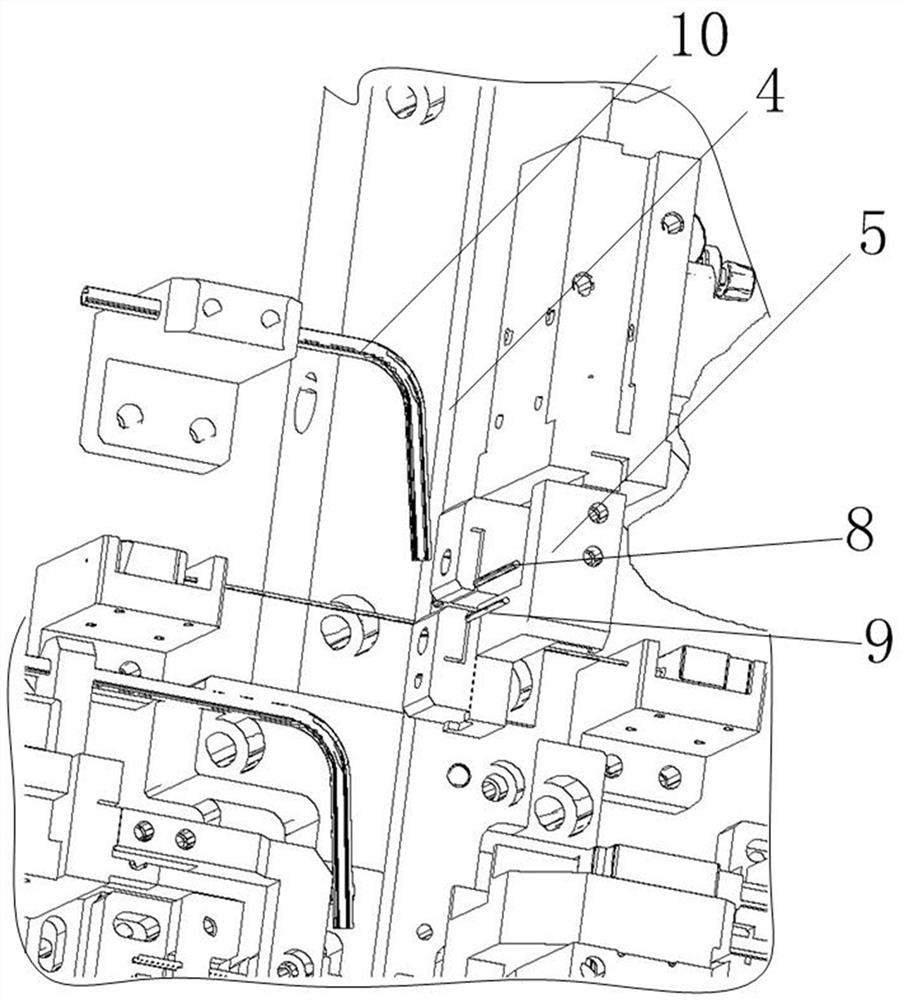

[0030] Such as figure 1 , 2 , 3, 4, and 5; SOT shape integrated circuit chip test and sorting device is used for automatic test and sorting of microchips, and the test and sorting device includes feeding mechanism, test track 4, separator 5, classification storage Storage module 7, industrial computer and some test stations 13,14; The beginning end of described test track 4 is adjacent to feeding mechanism, and the end of test track 4 is adjacent to classification storage module 7; Described separator 5 and test station 13 and 14 are adjacent to the test track 4 and arranged sequentially in the chip delivery direction of the test track 4; when the device is working, the microchips are input into the test track 4 through the discharge port of the feeding mechanism, and the separator 5 pairs of microchips are placed on the test track. The transportation on the board is controlled so that the chips arrive at each test station 13,14 in an orderly manner.

[0031] Described sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com