Processing equipment for positioning welding angle through infrared rays

A technology of positioning welding and processing equipment, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problem of lack of auxiliary equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

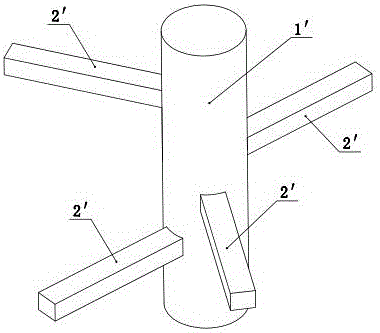

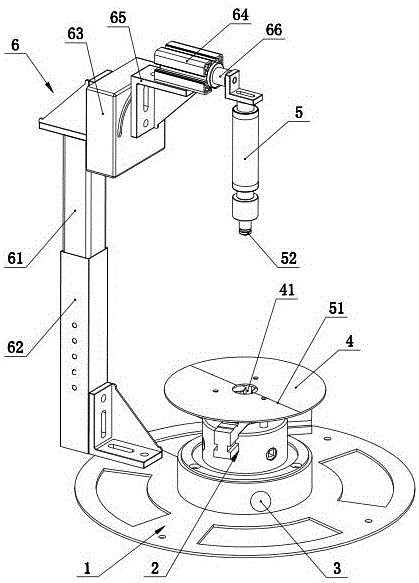

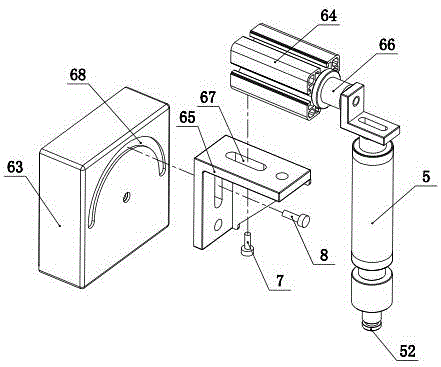

[0013] Such as figure 2 , 3 The shown shows a processing equipment for positioning the welding angle by infrared rays, including a chassis 1, a three-jaw chuck 2 is rotated on the chassis 1, and the three-jaw chuck 2 is correspondingly connected to drive it to rotate on the chassis 1. The handle 3. The three-jaw chuck 2 is coaxially fixed with a dial 4, and the center of the dial 4 is provided with a central through hole 41 communicating with the three-jaw chuck 2, and the upper end surface of the dial 4 is evenly distributed around the center through hole 41. From the scale line of 0 to 360 degrees, the top of the dial 4 is provided with an infrared laser head 5 that can irradiate infrared rays 51 thereon, and the emitting end of the infrared laser head 5 is provided with an angle for changing the emitted infrared rays 51 The rotating head 52, the infrared laser head 5 is movably installed on the chassis 1 through the connecting mechanism 6. The connecting mechanism 6 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com