Seal clamp

A technology of sealing clips and pressing plates, applied in the field of sealing clips, can solve problems such as air leakage, and achieve the effect of ensuring product quality, avoiding air leakage problems and preventing discounts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

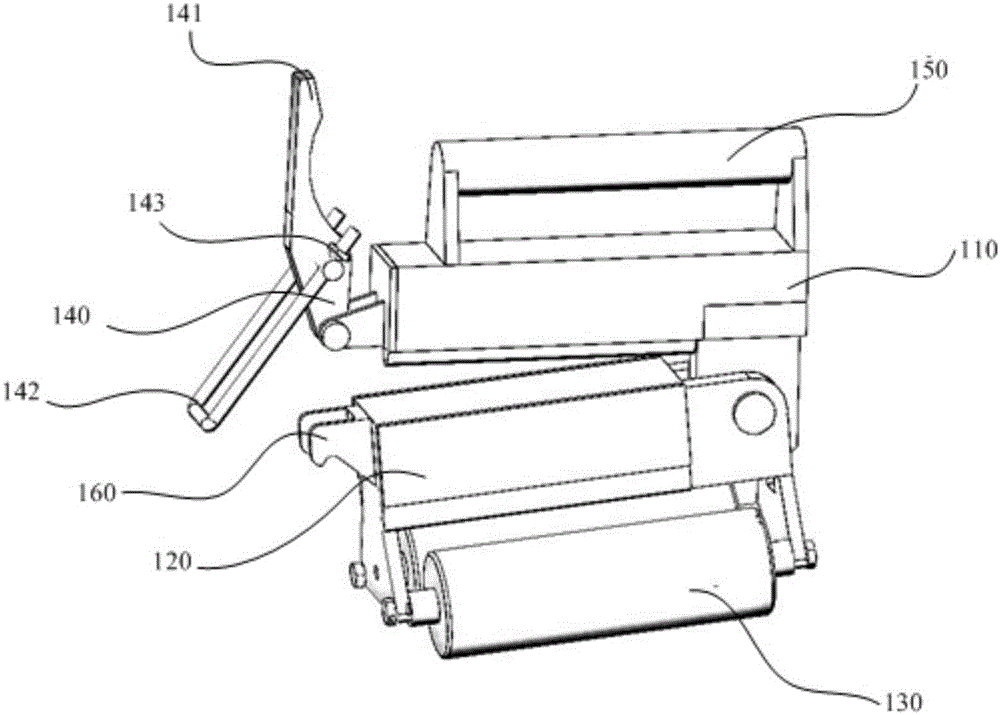

[0023] In view of the prior art, in the manufacturing process of the heat-shrinkable tube, the online cutting of the expansion of the circular tube, the cutting under the existing conditions will cause air leakage, which will affect the stability of the expansion and ultimately affect the quality of the product. The invention designs a special sealing clip, which is placed on the round tube product just after the expansion mold when the heat-shrinkable tube is expanded, which can play a good sealing role, and can realize expansion while cutting, avoiding the expansion of the tube The air leakage problem during the cutting process improves the stability of the expansion and ensures the product quality.

[0024] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com